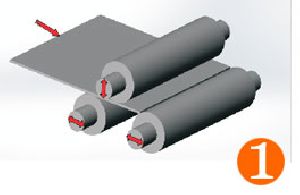

Three Roll Variable Axis Machine

Our Three Roll Variable Axis Machine is built in pre-pinching within machine and is provided with bottom rollers which can be adjusted in horizontal axis direction & top roller adjustable in vertical axis direction. Centre distance between bottom rollers can be varied easily in our Three Roll Variable Axis Machine. Cone bending can be obtained with heavy thickness and standard size bearings are used for low friction and easy maintenance in our Three Roll Variable Axis Machine.Highlights Reduced friction Easy to maintain Easy variation in rolls possible Enables cone bending of heavy thickness

...more

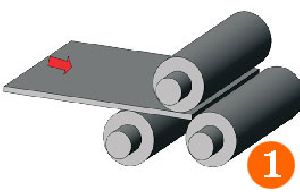

Three Roll Variable Axis

General Description As the name indicates the variable axis plate bending machine have all 3 rolls which changes its axis as per rolling needs. The top roll moves up and down and both side rolls move in and out horizontally giving advantage of reducing bottom roll centre to form small diameter and medium thickness shell rolling and also by increasing bottom roll centre one can roll large diameter and heavy thickness shell. The another main advantage of machine is that the working height is much less compared to 3 roll/4 roll planetary axis machine. Also mac hine up to capacity of 50 mm plate bending may not need any foundation. The variable axis machine can also work as a press for plate straightening application and is also capable to roll conical shapes to almost 80% values that of machine specified capacity by using it as press.

...more

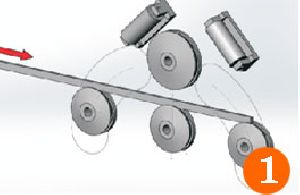

Three Roll Section Bending

General Description The latest in the 3 roll section bending machine design which gives advantage of 4 roll machine ( the bottom roll workind as a pinch roll) which enables clamping of sections at the centre between top and bottom roll to reduce distance between pinch roll and bending roll Due this working principle of machine the straight portion of section is at minimum which increases effective material utilisation.

...more

Three Roll Linear Axis Machine

Three rolls are used in Three Roll Linear Axis Machine to bend and pre-pinching of plate. Side rollers provided in Three Roll Linear Axis Machine moves in linear direction and the working of Three Roll Linear Axis Machine is similar to four roll linear axis plate bending machine. The only difference is that the bottom roller in Four Roll Linear Axis supports plate in bending of plate, and in Three Roll Linear Axis Machine side rollers do the same.Highlights Perfect bending Less friction Longer life Wide range of uses

...more

Three Roll Fix Axis

General Description As shown the machine is most suitable as a replacement to conventional plate bending machine where pre bending is done manually or on press machine outside and then inserted to machine for rolling purpose.The machine is most economical model among all plate bending machine and is most useful for small fabrication shop as well as the shop having separate press machine on which pre bending can be carried out.Since this is a rolling only machine all the power is available for rolling purpose and one can roll smallest possible diametrer for heavy thickness plate material.The same machine can also used for plate straightening machine for small left over rolled material which is to be reused after straightening.Also rerolling is easily possible in this machine which enables apple effect correction and out of roundness correction to make it a perfect circular shape to component.

...more

Roll Planetary Axis

General Description The three roll Planetary axis is a three roll machine having pre pinching/pre bending facility within the machine.The plate can be inserted from one side and is clamped between top roll and one of the pressure roll for a firm grip and the another pressure roll advances further to form desired radious of shell. The same procedure is repeated but on another side of plate to form desired radiouse.After having done pre pinchind the plate is formed in to circular shape by rolling and further pressing of pressure rolls and by forward and reverse movement of rotation by rolls.Usually a shell is formed in multiple passes of rolling by forward and reverse movement of rolls in rotary motion.It is also possible to form shell in a single pass provided the pressure roll position is well known for particular size of shell rolling by regular practice and experience.The PLC based machine is most suitable for repetitive type of jobs and shapes required regularly Other shapes can also be forme in this machine in single pass like square, polycentric,elliptical or open rolling.

...more

Plc Based Plate Bending Machine

We offer PLC Based Plate Bending Machine which comes with totally four rolls. The rolls move in a planetary movement in PLC Based Plate Bending Machine about a fixed pivot to get pre bending and bending of edges. Only 3 rolls out of 4 rolls are driven several times to get bending. Our PLC Based Plate Bending Machine offers bending in several shapes like square, round, polycentric, oval parallel and elliptical. Highlights Offers bending in several shapes Comes with programmed logic control Premium quality Durable

...more

Moving Control Console

We are a prominent Manufacturer and Supplier of Moving Control Console. Generally, Moving Control Console comes with portable/moving operator console to facilitate ease of access to other side of machine along with control panel. This avoids the requirement of additional manpower which otherwise will be needed to have idea about sheet advancement on other side. Our Moving Control Console eases the control and is used in several devices.Highlights Offers easy control Excellent quality Longer life Market leading prices

...more

Hydraulic Four Roll Plate Bending Machine

We offer high quality Hydraulic 4 Roll Plate Bending Machine to the clients. Hydraulic 4 Roll Plate Bending Machine, offered by us, finds uses in numerous manufacturing industries. Our Hydraulic 4 Roll Plate Bending Machine has features such as overload protection, correction of axial offsets, simple cone bending, and pre bending of sheet edges. Our Hydraulic 4 Roll Plate Bending Machine is suitable for light and medium aluminum or stainless steel plates. Highlights Overload protection Offers simple cone bending Easy to operate

...more

Hydraulic 4 Roll Plate Bending Machine

We offer high quality Hydraulic 4 Roll Plate Bending Machine to the clients. Hydraulic 4 Roll Plate Bending Machine, offered by us, finds uses in numerous manufacturing industries. Our Hydraulic 4 Roll Plate Bending Machine has features such as overload protection, correction of axial offsets, simple cone bending, and pre bending of sheet edges. Our Hydraulic 4 Roll Plate Bending Machine is suitable for light and medium aluminum or stainless steel plates. Highlights Overload protection Offers simple cone bending Easy to operate

...more

Hydraulic Three Roll Plate Bending Machine

We are a prime manufacturer and supplier of superior quality hydraulic 3 roll plate bending machine. Hydraulic 3 roll plate bending machine, offered by us, delivers perfect bending results due to total machine symmetry. Rolls provided in our hydraulic 3 roll plate bending machine are crack resistant and one can have an excellent operator view of bending processes. attributes provides excellent bending results equipped with crack resistant rolls offers simple cone bending quality assured

...more

Hydraulic 3 Roll Plate Bending Machine

We are a prime Manufacturer and Supplier of superior quality Hydraulic 3 Roll Plate Bending Machine. Hydraulic 3 Roll Plate Bending Machine, offered by us, delivers perfect bending results due to total machine symmetry. Rolls provided in our Hydraulic 3 Roll Plate Bending Machine are crack resistant and one can have an excellent operator view of bending processes. Attributes Provides excellent bending results Equipped with crack resistant rolls Offers simple cone bending Quality assured

...more

Four Roll Section Bending

General Description In this type of 4 roll section bending machine the bottom roll works as apinch roll and the material is clamped firmly betwwen top and bottom roll .The side roll advances to give desired radious of bending Since the bending force is applied nearer to clamping point the unbend portion of section left straight is at minimum. Due this working principle of machine the straight portion of section is at minimum which increases effective material utilisation.

...more

Four Roll Planetary Axis

General Description The working principle of 4 roll plate bending machine is similer to that of 3 roll plate bending machine but only the difference being it has one extra roll below the top roll which works as a clamping roll or more commonly known as pinchincing roll.The main advantage is that the plate can be feed horizontally since the bottom and one pressure roll work as a support roll for plate ( in case of 3 roll machine plate is required to feed in a slant position)Also the pressure roller on opposite side works as a reference surface and plate can be fed at perfect right angle to pressure roll or machine.After the plate is held firmly between top roll and pinching roll , the pressure roll advances to form desired radius on plate edge and adjacent area as shown The radius thus formed is checked with the template and same procedure is repeated till the template matches with pre bent/pre pinched edge of plate.After pre pinching the one edge of plate the same procedure is repeated on the another edge of plate to form pre pinching radius.After forming desired radius on both the edges ,the rolling/bending is carried our by rotating all rolls in a reverse and forward direction till the complete circle is formed.It is possible to form different shapes like square, rectangle, polycentric, elliptical,etc shapes more precisely ,but it is must that this are formed in a single pass and machine with PLC based controls is most suitable for this application.Also this machine is most suitable for mass production type components which requires repeatedly same output results mass.For engineering shop where same size of rolled products are required to be produced in small quantity and the sizes may change on day to day basis depending on job type ,the shell can be produced by rolling completed in multiple pass.

...more

4 Roll Plate Bending Machine

We bring forth a wide array of 4 Roll Plate Bending Machine in the market. The 4 Roll Plate Bending Machine has greater efficiency and can perform pre pinching & bending a plate in single pass. There is no sliding friction and full power is utilized for bending, in our 4 Roll Plate Bending Machines. The 4 Roll Plate Bending Machine moves in planetary motion. The 4 Roll Plate Bending Machine can roll more diameters as compared to 3 Roll Plate Bending Machine. The two rollers associated at top and bottom in 4 Roll Plate Bending Machine are operated by G.B. and motor.Attributes No sliding friction High efficiency Easy to operate Low maintenance Minimum Diameter : 1.1 times the top roll diameter Power Utilization : 30%

...more

3 Roll Plate Bending Machine

We are one of the renowned Manufacturers and Suppliers of a wide array of 3 Roll Plate Bending Machines. The 3 Roll Plate Bending Machine has infinitely variable speed of rolling as per requirement. These 3 Roll Plate Bending Machines have faster rolling for smaller thickness. We provide these 3 Roll Plate Bending Machines at rock-bottom prices. The 3 Roll Plate Bending Machines are operated easily and are highly durable.Width : 2000mm, 2500mm, 3100mm, 3600mm & 4100 mm. Capacity in Thickness : 12, 16, 20, 25 & 30 mm. Standard Features : Hardened rolls up to 60 R. C. Cone guide adjustable on button section rolling arrangement digital display for pressure arm A & B. Optional Features Soft rolls frame mounted cone guide roller Fully ground Plated and polished rolls for SS, copper or CRC Rolling interchangeable profile rolls with/without PU coating for thin & coated metal rolling in profile like GI/color coated sheets Material feed table Vertical support for large diameter rolling & shell support Hardened section bending dies for angle channel, beam, pipe etc. Moving console for all around operator movement NC/ CNC control for mass production Infinitely variable roller speed Automatic central lubrication system Unique Features Control Panel : The control panel is user friendly & most convenient to operate. All functions like, bending, cylinder movement, cone guide, drop-end, hold & roller rotation start/stop is on panel. Operator can see bending cylinder position as digital display on panel. Drop End : Most convenient & easy way to remove rolled shell from machine due to more clearance between bottom & top roll & higher degree of inclination of top roll. Cone Guide : Cone guide which is must for taper/conical rolling is provided to be operated by push button & is duly hardened to 55-60 RC hardness with heavy duty bearing within & to be operated from panel. Section Bending : An extended shaft provided on both top & bottom roller to facilitate die mounting which enables bending of different sections like, beams, channels, angles, pipes, flats, round/square bar bending. Capacity up to size 200 channel & beam. The operation is by push button on panel. Greater Tilting Angle : Greater tilting angle for taper shell rolling with major dimensional difference between small & large diameter.

...more

Cnc 4 Roll Plate Bending Machine

We are a prominent Manufacturer and Supplier of CNC 4 Roll Plate Bending Machine that is highly acclaimed for its robust construction and high operational efficiency with longer service life. CNC Three Rolls Plate Bending Machine has such a plate arrangement to create a pass between upper and lower gripping rolls in parallel positions. These rolls are connected to a drive motor for rotation to give a motion. Attributes High operational efficiency Has crack resistant rolls Delivers excellent bending Quality assured

...more

Cnc Three Rolls Plate Bending Machine

Our CNC Three Rolls Plate Bending Machine is used for roll bending of metal plates in several industries. CNC Three Rolls Plate Bending Machine has pre-bending feature of up to 3000 mm in length that is highly efficient for heavy plates. Our CNC Three Rolls Plate Bending Machine is made up of premium spare parts so that bending work can be executed precisely across the width and length of the plate. CNC Three Rolls Plate Bending Machine is designed and developed as per the international quality standards and can be customized as per the client requirements at affordable prices.Attributes High efficiency Precise bending Crack resistant rolls Market leading prices

...more

Four Roll Linear Axis Machine

Our Four Roll Linear Axis Machine uses four rollers for the bending of the plate. Our Four Roll Linear Axis Machine is frequently used in pre-bending of plate. During operation, side rollers moves in linear direction & bottom roller moves in vertical direction and this machine rolls more tighter diameter. Our Four Roll Linear Axis Machine uses bearings for friction and power loss reduction which ensures long life of machine. Our Four Roll Linear Axis Machine is mostly used in heavy type of applications.Highlights Delivers excellent bending Reduced power loss Reduced friction Crack resistant rolls

...more

Roll Bending Machine

The machine is most economical model among all plate bending machine and is most useful for small fabrication shop as well as the shop having separate press machine on which pre bending can be carried out. Since this is a rolling only machine all the power is available for rolling purpose and one can roll smallest possible diametrer for heavy thickness plate material. The same machine can also used for plate straightening machine for small left over rolled material which is to be reused after straightening. Also rerolling is easily possible in this machine which enables apple effect correction and out of roundness correction to make it a perfect circular shape to component.

...more

Hydraulic Plate Bending Machines

The main advantage is that the plate can be feed horizontally since the bottom and one pressure roll work as a support roll for plate ( in case of 3 roll machine plate is required to feed in a slant position)Also the pressure roller on opposite side works as a reference surface and plate can be fed at perfect right angle to pressure roll or machine. After the plate is held firmly between top roll and pinching roll , the pressure roll advances to form desired radius on plate edge and adjacent area as shown The radius thus formed is checked with the template and same procedure is repeated till the template matches with pre bentpre pinched edge of plate. After pre pinching the one edge of plate the same procedure is repeated on the another edge of plate to form pre pinching radius. After forming desired radius on both the edges ,the rollingbending is carried our by rotating all rolls in a reverse and forward direction till the complete circle is formed. It is possible to form different shapes like square, rectangle, polycentric, elliptical,etc shapes more precisely ,but it is must that this are formed in a single pass and machine with PLC based controls is most suitable for this application. Also this machine is most suitable for mass production type components which requires repeatedly same output results mass. For engineering shop where same size of rolled products are required to be produced in small quantity and the sizes may change on day to day basis depending on job type ,the shell can be produced by rolling completed in multiple pass.

...more

plate roller

. The main advantage is that the plate can be feed horizontally since the bottom and one pressure roll work as a support roll for plate ( in case of 3 roll machine plate is required to feed in a slant position)Also the pressure roller on opposite side works as a reference surface and plate can be fed at perfect right angle to pressure roll or machine. After the plate is held firmly between top roll and pinching roll , the pressure roll advances to form desired radius on plate edge and adjacent area as shown The radius thus formed is checked with the template and same procedure is repeated till the template matches with pre bentpre pinched edge of plate. After pre pinching the one edge of plate the same procedure is repeated on the another edge of plate to form pre pinching radius.

...more

section rolling machine

In this type of 4 roll section bending machine the bottom roll works as apinch roll and the material is clamped firmly betwwen top and bottom roll .The side roll advances to give desired radious of bending. Since the bending force is applied nearer to clamping point the unbend portion of section left straight is at minimum. Due this working principle of machine the straight portion of section is at minimum which increases effective material utilisation. features Both the bottom rolls are positively driven by palnatery gear box and hydraulic motor directly mounted in line with roll shaft The swinging control console gives liberty to operate machine from front or from one side which also makes it possible to remove rolled sections from front without any problem. All our section bending machine model comes with roller mounted in ball bearing which reduces friction and enhanced torque is available for rotation which other wise will go to waste if plain bush are use which create lot of friction due to metal to metal friction.

...more

section bending machines

In this type of 4 roll section bending machine the bottom roll works as apinch roll and the material is clamped firmly betwwen top and bottom roll .The side roll advances to give desired radious of bending. Since the bending force is applied nearer to clamping point the unbend portion of section left straight is at minimum. Due this working principle of machine the straight portion of section is at minimum which increases effective material utilisation

...moreBe first to Rate

Rate This