Uht Sterilizer

HRS advantage is extended to the dairy industry through state-of-art systems such as PHE based pasteurisers, chillers, inoculation tanks and many more solutions for milk, cream, whey, whey cream, yoghurt, curd milk and allied products. The UHT Sterilizer by HRS is based on ultra heat treatment technology and has a complete hygienic design to give the final output. It can be customized to suit varied capacity and a special provision for future capacity expansion is an additional advantage. This system works on the principle of sterilization which allows heating milk at ultra high temperature and then cools it to ambient temperature for further input to desired aseptic packaging line. UHT Sterilizer ensures correct quality of end product with its special features and PLC automation controls which enable flawless operation with minimal manual interference. It is programmed to perform CIP automatically and efficiently.

...more

Smooth Tube Heat Exchangers

HRS Process Systems Limited also designs and manufactures ECOFLUX* Smooth Tube Heat Exchanger for various industrial application like heating, cooling, condensing and reboiling in our world class manufacturing facility to cater to Customer's heat transfer requirement. We manufacture units presently to working pressure of 80 bar for process service plant and with 0 temperature upto 400 C. For specific design we can manufacture units with 150 bar pressure at 500 C. Our manufacturing facility is equipped to fabricate STHE with diameter of 2000 mm and tube length upto 9000 mm. For special equipment we can make heat exchanger with 12000 mm tube length. These are customised units based on specific industry application. The units can be fabricated based on customer drawings. We can design and manufacture units to customer specifications too. We design STHE with or without ASME 'U' stamp certification, CE certification and others codes. Heat exchangers are manufactured in Stainless Steel AISI 304/316, depending upon the application. Material like SS304L, SS316L, Hastelloy, Copper, Cu-Ni alloys, Titanium, AL6XN can also be offered.

Speciality : Flexible in design, customised solution,Suitable for high temperature & presure applications etc.

...more

Scraped Surface Heat Exchanger

Pre-heaters systems

HRS Process System Ltd. offers specialized solutions for pre-heating and pasteurisation of fruit pulp. Concentrated fruit pulp normally has high fiber and sugar content and also contains considerable plant cellular material as compared to juice. HRS ECOFLUX* based pre-heaters, pasteurisers heat the product to desired temperature and holding it for appropriate time for inactivation of microbes. The preheating or pasteurization system can be integrated with evaporators, sterilizers and fillers as per customer requirement. Accurate automation through these systems minimizes intervention of operator thereby reducing errors. Additionally, HRS also provides systems for chilling or freezing pulp as required for frozen pulp filling and storage.

...more

Nutraceuticals Processing Systems

HRS provides Nutraceutical processing systems to food and healthcare industries. Good quality nutraceuticals, probiotic health supplements and infant food substitutes are some of the key requirements of modern consumer. This advanced system is integrated with Ecoflux* DT series based pasteurizer and Ecoflux* MI series water heater to form the powder mixing section, powder solution processing section and oil storage and dosing section. The powder mix section includes a tri-blender, mixing cum storage tank and tubular heat exchangers for water RO heating. Superior quality pumps are used for powder and essential nutrient mixing and dosing. An independent multiple circuit CIP system is engineered with the nutraceutical processing system for large plants. The entire integration can be done with separate control panels for main unit & CIP system.

...more

Integrated Automated CIP Station

HRS excels in design and supply of integrated and sophisticated centralised CIP systems. Such systems are advantageous in reducing the consumption of water, chemicals, steam and power; eventually reducing the effluent discharge. This approach is advancement to local CIP setup, where each machine has an independent CIP module. The CIP solution is heated in heat exchanger provided with steam and condensate setup. Multiple tanks are provided each for water, caustic and acid solutions. High capacity centrifugal pumps are provided to match the plant capacities. The number of CIP circuits and the volume of the tanks are decided depending on the plant area and number of systems to be cleaned. In large systems mix proof valves are provided to isolate the CIP circuits from one other.

Features : Data acquisition with SCADA,Design conformation with 3A, USDA, FDA and PMO standards etc.

...more

hygienic piston pumps

Traditional pumping systems for particulate products have always been a daily problem for all processors who need to move or pump whole or diced fruits or vegetables. Problems caused by the high cost of triplex piston pumps, the poor efficiency of lobe pumps, the damaged product resulting from the use of screw pumps, or the low pressure losses which double diaphragm pumps need. The HRS Piston Pump is of a completely hygienic design, and incorporates a separator fitted between the pump and the hydraulic chamber to ensure that there is no contact between the product and hydraulic oil. The hygienic design combined with a perfect response to CIP cleaning makes this pump so suited to food processing applications where product integrity and shape must be guaranteed, to maintain both appearance and nutritional quality.

...more

hygienic piston pump

Traditional pumping systems for particulate products have always been a daily problem for all processors who need to move or pump whole or diced fruits or vegetables. Problems caused by the high cost of triplex piston pumps, the poor efficiency of lobe pumps, the damaged product resulting from the use of screw pumps, or the low pressure losses which double diaphragm pumps need.

Pressure : 20 bar,30 bar,16 bar

...more

HRS Para Dice Heat Exchangers

HRS ParaDice* is a unique offering for dices and ready to eat food processing industry which is capable of processing fruit dices vegetable dices without shearing them. In this cutting edge solution, dices are pumped using HRS Hygienic Piston Pump and are heated and cooled in the highly efficient ECOFLUX* Double Tube Heat Exchangers. The fruit dices can be pasteurised or aseptically processed using the ParaDice*. HRS ParaDice* can be used for processing diced fruits, particulate foods, blanching of vegetables, pasteurisation and chilling of Ready-to-Eat foods, and similar applications.

...more

HRS Monobloc Steriliser

HRS latest offering to food processing sector is the HRS Monobloc Steriliser . This state of art system provides hygienic and innovative processing advantage along with bringing global technology to our customers. The HRS Monobloc is an integration of the Aseptic Steriliser and Aseptic Filler on a single skid fully automated with PLC based controls. Designed to process varying capacities up to 9000 kg per hour of fruit pulp puree concentrate of high viscosity. The heart of the Aseptic Steriliser are the Ecoflux* AS series Corrugated Tube Heat Exchangers to enable processing of the product at desired temperature range, a piston pump for homogenizing and de-aerator with automatic vacuum control system supported with CIP pump and peripherals. The filling section of the HRS Monobloc Steriliser is with the Aseptic Filler which has fully automated, double filler heads with bag clamping system, conveyor to support the drums and a sanitary steam line for sterilisation of the filling chambers.

Features : Bag-in-drum filling mechanism,Integrated CIP dosing system,Complete PLC based automation etc.

Applications : Concentration of fruit pulp, purees, paste,Aseptic Sterilisation and Filling of fruit and vegetable

...more

HRS Hot Water Systems

HRS Hot Water System is the most versatile and compact hot water generation system. It provides highly efficient solution to instantaneous hot water generation using energy efficient heat exchangers (Funke Brazed or Gasketed plate heat exchanger or Ecoflux* corrugated tube heat exchanger. HRS Hot Water Systems can also be installed with storage (buffer) vessel for semi-instantaneous applications and in conjunction with solar based hot water systems. A Hot water system not only heats the water to a desired temperature using low pressure steam but also maintains the required temperature of water with better temperature control using automation and control.

Application : Acid heating for steel plate pickling line.

...more

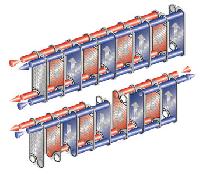

Heat Exchanger Based Systems

HRS Process Systems offers customised heat exchanger based systems (HES) as innovative heat transfer solutions for various key applications across process industry sectors. This is in line with the global reputation of HRS for providing sustainable, energy efficient range of heat exchangers and heat exchanger based systems (HES). HRS Heat exchanger based systems (HES) are usually skid mounted systems complementing the main plant. Through good process expertise, our systems ensure to recover energy which would otherwise have been lost to environment, thus making the overall plant much more environmentally efficient. HRS heat exchanger based systems (HES) are made for key applications like instantaneous hot water generation as 'hot water systems','acid heating', 'emulsion heating', 'heat recovery from waste condensate' and many more applications. As a customized solution, HRS HES can be designed to use across a wide spectrum of industries like pharmaceuticals, HVAC, hotels, hospitals, steel, textile, food processing, beverage processing, breweries, dairy, healthcare and many more allied sectors. HRS heat exchanger based systems (HES) are primarily used for heating, cooling, condensation and similar operations for efficient use of thermal energy. These skids are comprised of HRS range of heat exchangers (tubular heat exchangers or plate heat exchangers or a combination of these and any other heat exchangers as suited to the process) along with pumps, valves and suitable automation for ease of operation. HRS always ensures high quality components in the systems. The heat exchangers are manufactured in a range of materials like higher grades of stainless steel, nickel alloys, hastelloy, duplex, alloy 20, titanium, tantalum, etc., depending on property of fluid and process requirement. HRS Process Systems also has established a trusted partnership with food processing industry for fruit pulp, foods, prepared foods, infant foods, probiotics, etc. for more evolved processes like heating, cooling, condensing, evaporation, aseptic processing and more... HRS heat exchanger based systems (HES) have given customers the advantage of energy efficiency, better utilization of energy release to environment, higher productivity due to continuous running of plants and lower downtimes, and better savings on maintenance costs. These solutions have enabled enhance production capacities, thereby increased profitability for the plants. A wide industry spectrum with blue chip companies has benefitted from these heat exchanger based systems.

...more

Heat Exchanger

heat exchanger for difficult and critical processes where other types of heat exchangers such as rotary scraped surface heat exchanger, shell and tube or plain type are incapable of offering an adequate solution. Unicus® is capable of generating high levels of turbulence in products of high viscosity increasing substantially the overall heat transfer coefficient. In addition it does not allow the formation of any fouling layers on the inner tube surfaces and always stays clean enabling the unit to work in the optimum condition for efficient heat transfer at all times.

...more

Gaskets Materials

All gaskets are installed twice in the entry and exit area, creating a safety room which is open to the outside. It prevents the two media from mixing if the gasket leaks.

...more

Vegetables Evaporation System

In Food applications, concentrating fruit pulps for bulk transportation and reduction of water activity for longer shelf life necessitated the concept of evaporation. Evaporation is the process of vaporizing the water from a solution to produce concentrated product. HRS PSL provides evaporation systems of tubular and scraped surface type, to obtain the best thermally stable product, with capacity up to 20 tonhour.

...more

Emulsion Circuit Reheating System

HRS Process Systems Ltd. offers customized Heat exchanger based systems for various key applications in steel industry. This System comprises of Ecoflux* Corrugated tube Heat Exchanger along with all accessory and controls to ensure required temperature of emulsion.

Application : Emulsion Heating for various steel manufacturing processes.

...more

ECOFLUX* Smooth Tube Heat Exchangers

HRS Process Systems Limited also designs and manufactures ECOFLUX* Smooth Tube Heat Exchanger for various industrial application like heating, cooling, condensing and reboiling in our world class manufacturing facility to cater to Customer's heat transfer requirement. We manufacture units presently to working pressure of 80 bar for process / service plant and with 0 temperature upto 400 C. For specific design we can manufacture units with 150 bar pressure at 500 C. Features: Flexible in design, customised solution Suitable for high temperature & presure applications Thermal design in HTRI and Chemcad Software Mechnical design in PVD and PV Elite Software TEMA configurations available like BEM, BET, BKU, AES, AEL, etc. Wide choice of Material of Construction Our manufacturing facility is equipped to fabricate STHE with diameter of 2000 mm and tube length upto 9000 mm. For special equipment we can make heat exchanger with 12000 mm tube length. These are customised units based on specific industry application. The units can be fabricated based on customer drawings. We can design and manufacture units to customer specifications too. We design STHE with or without ASME 'U' stamp certification, CE certification and others codes. Heat exchangers are manufactured in Stainless Steel AISI 304/316, depending upon the application. Material like SS304L, SS316L, Hastelloy, Copper, Cu-Ni alloys, Titanium, AL6XN can also be offered.

...more

Ecoflux* Corrugated Tube Heat Exchanger

Ecoflux* Corrugated Tube Heat Exchangers (CTHE) use corrugated tubes instead of smooth tubes. The corrugations induce turbulence in the media and ensure high Reynolds number even at low velocity. The development of corrugated tube is perhaps the most exciting advancement in heat transfer technology. Corrugated tube is produced by indenting a plain tube with a spiral pattern. No tube wall thinning takes place & no strength is lost. Features A smooth indented inner profile ensures easy cleaning Turbulence is created at low fluid velocities to enhance the heat transfer in the tube Fouling on the tube surface is minimised A wide range of diameters & styles are available Technology:Corrugated tube is produced by indenting a plain tube with a spiral pattern. This imparts different flow regimes - spiral in the core and eddy's at the periphery. The helical flow contributes to the situation that the fluid particles are alternatively in the vicinity of the tube wall and then in the main flow. Between the helical impressions, around the circumference of the tube, secondary flow, typically in the form of eddies occur. The flow regime ensures that the rate of decrease in boundary layer resistance exceeds the rate of increase in pressure loss. In other words high heat transfer coefficients with minimum increase in pressure drop. Hydrodynamic Thermal Boundary LayerIncrease in heat transfer coefficient brings the temperature of the tube wall closer to the temperature of the bulk fluid on the tube. The roughness elements need to have a minimum height so as to influence the flow ( Fig. A ) and thus the heat transfer ( Fig. B ). To ensure that the heat transfer is improved by roughness elements, the flow must be influenced within the heat conduction layer. Advantages:Corrugated tube shell and tube heat exchangers have many benefits and advantages over comparable smooth tube versions: Compact tubular heat exchanger Long running times due to turbulent flow Very low maintenance costs, minimum spares requirement Higher heat transfer coefficient (2-3 times) results in reduction in heat exchanger area upto 50% Fouling is minimised due to turbulence created by eddies at the periphery or tube wall High response to CIP Wide choice of MOC Uniform thermal processing More flexibility in annular space sizing

...more

Corrugated Tube Heat Exchanger

Ecoflux* Corrugated Tube Heat Exchangers (CTHE) use corrugated tubes instead of smooth tubes. The corrugations induce turbulence in the media and ensure high Reynolds number even at low velocity. The development of corrugated tube is perhaps the most exciting advancement in heat transfer technology.

...more

Beverage pasteurizer processing lines

HRS is one of the leading suppliers of pasteurisers and complete beverage processing lines for fruit based non carbonated beverages. Juice pasteurization is one of the key processes of beverage production which ensure inactivation of micro-organisms and achieve desired shelf life. HRS beverage processing plant starts from preparation section and continues till pasteurisation. This integrated beverage processing line includes sugar syrup preparation, pulp unloading, ingredient dosing sections, beverage blending section, ready beverage storage section, beverage pasteuriser and a centralized CIP station. As required by customer, separate blending and pasteurization systems can also be provided.

...more

aseptic fillers

Aseptic Filling Equipment Manufacturer India, Aseptic Fillers, Aseptic Filling Process In order to satisfy the demands of the modern food-processing sector HRS Process Systems has taken a decisive step in the integration of technologies. We have developed an integrated system which combines their innovative Hygienic Piston Pump, Unicus® dynamic heat exchangers, Ecoflux*corrugated tube heat exchangers depending on the process and their bag-in-drum Aseptic Fillers.

...more

Aseptic Filler

In order to satisfy the demands of the modern food-processing sector HRS Process Systems has taken a decisive step in the integration of technologies. We have developed an integrated system which combines their innovative Hygienic Piston Pump, Unicus® dynamic heat exchangers, Ecoflux*corrugated tube heat exchangers depending on the process and their bag-in-drum Aseptic Fillers.

...more

Acid Heating System

HRS Process Systems Ltd. offers customized Heat exchanger based systems for various key applications in steel industry. Acid Heating System comes with ECOFLUX* heat exchanger in Tantalum at its heart along with special piping, pumps, valves, steam trap, control panel unit with automated flow & temperature controls.

Feature : Compact and Complete Package Solution, Pre-assembled skid for ease of installation etc.

Application : Food,Breweries,Hotel,Textile etc.

...more

Ammonia Gas Condenser

Plate Heat Exchanger Design services

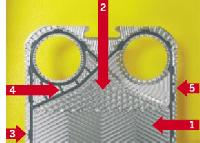

The heart of a PHE is a pack of embossed plates with apertures. The plates are assembled in a 180° angle to each other, resulting in flow gaps on each side. Each plate is provided with a gasket, which securely seals the flow gaps from the atmosphere and separates the two media used in the heat exchange. The gasketed plate pack is mounted in a rack and is compressed with tightening bolts between the fixed plate and the movable plate. To guarantee maximum heat transfer, warm and cold media are normally fed through the PHE in one-pass or multi-pass counter flow.

...moreBe first to Rate

Rate This