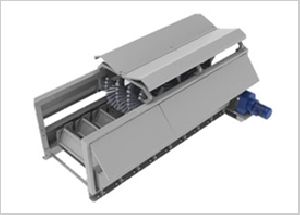

SCREW SAMPLERS

IFI understands the need for accurate & continuous sampling of Raw Materials and finish products in various industries. To meet these requirements IFI has designed and manufactured in house Screw Samplers to meet the quality requirements of the industry. The screw sampler is designed for sample extraction of dry and non-sticky powdered material from a duct or chute through which free flow of material is taking place. The sampler is driven by a geared motor coupled to a transport screw, crossing the flow of material. As an option, the screw sampler can be equipped with variable speed geared motor. The screw transports the extracted material to a discharge outlet chute where the material falls by gravity to the subsequent sample preparation equipment. The screw sampler type size and design is based on chute dimension in mm as well as chute form. It can be mounted in chutes (rectangular or circular) The control of the sampler is normally conducted from your central PLC system or local control is also possible. It can be equipped with a motion detector as an option. Manual type Screw Samplers are also available upon request.

...more

SACK SWEEPER

Cleans the sack from bottom, sides and top Installed at the sack discharge end of Rotary Packer. Recovers the spillage and dust on the sack Keeps the packing area clean Improves the working environment Uses the draught of the packer No extra air used Single drive in the form of geared motor The main module has pedestals at inlet and outlet which can be adjusted to match with the upstream and downstream of the equipment. This ensures smooth movement of the bags during transfers. The bed of the sack sweeper is made of powered rollers. The hollow rollers are fitted with brush that rotates in the opposite direction to make the brushing effective. The top brushes are also powered and fitted with bristles that can clean the sacks from top and sides. The level of the top brush can be adjusted to compensate the reduced length of the brush when it wears off. Safety covers are fitted on both sides. These covers are loaded with gas springs for ease of opening and closing. The drive is in the form of cascaded chains and sprockets – powered by a geared motor. The drive can be located on either side of the sack sweeper. The rpm of the geared motor can be chosen to suit the packer throughput. Top bonnet can be opened and closed with ease with the help of gas springs. Emergency stop push buttons are provided in all the four corners of the sweeper module

...more

Programmable Sequential Timer

IFI's integrated programmable bag filter controller helps you get the best performance out of your Bag Filter.It integrates all important signals associated with a bag filter & produces the most efficient cleaning program. The Inputs & Outputs of the IPBC can be configured as per user requirement.Sequential Operation of Solenoid Valves for Cleaning, Monitors Pressure build up in Air Header, Rotary Air Lock Valve Motion, Differential Pressure Build up across Bag Filter, Functioning of Hopper Level Indicator.

...more

PRE FABRICATED PLATFORMS and STRUCTURES

IFI designs, manufactures & supplies customized platforms which are pre fabricated& to be erected at site. Customized designs allows us to make platform exactly as per user requirements so as to fit in existing space, around existing equipment’s and at varying heights. IFI has internal engineering facilities to design platforms which are load bearing platforms on case to case basis. Pre-fabricated platforms, staircases, ladders, railings allow easy erection at site which can be completed in the least possible time. Platforms can be made in various MOC’s like Mild Steel which can be Painted or Galvanized. Stainless Steel platforms can also be manufactured on request.

...more

POWDER DOSING SYSTEM

FI has been a pioneer in applying Air Pollution Control Techniques in day to day process operations. A striking example of this pioneering approach is IFI’s Simple & Efficient “Sack Feeding & Dosing system”. Compact, Sturdy & Ergonomically designed to suit various industrial applications. This unique equipment can be effectively used for dosing of various powders in the food, cosmetic, chemical and dairy industry. At the heart of IFI’s Dosing system is a custom designed Dust Filter with Cleaning Arrangement, a Fan optimally designed and a Screw Conveyor which feeds the desired quantity of material into the onward system.

...more

Hydraulic Slide Gate

Slide Gates are used to control and isolate the discharge of bulk materials from hoppers, bins, silos or conveyors.Slide Gates consist of a rigid frame mounted to the bottom of the storage device or conveyor.A slide plate is located inside the frame that either opens or closes against the flow of material. The slide plate can be moved by manual, pneumatic, electric or hydraulic means.

...more

Electrostatic Precipitator

There was a time when smoke bellowing out of a chimney was considered to be a sign of industrialization. In today’s environmentally cautious age—even the analysis of suspended particles in “visibly clean” gas is mandatory. ESP has proved itself time & again to be the most economical equipment for handling high volume gas. Thus making it the first choice for various industries. With Ever increasing number of industrial processes, the importance of the ESP has increased considerably. The latest advancements in Electronic Control Systems has proved itself in enhancing the reliability & performance of the ESP’s. IFI brings the latest in ESP Technology right to your door step to fulfill the ever increasing needs of the industry.

...more

CONTINUOUS EMISSION MONITOR

Emission Monitor model EM919 is an indigenous product for measuring dust concentration. This device operates on the principle of optical transmissometry, using single pass of a divergent light beam. It can be installed directly on the outlet stack. The dust concentration is measured depending upon the amount of light blocked by suspended articles in exhaust gas. Advanced techniques are effectively used to detect & compensate for errors due to ambient light as well as stationary dust giving accurate emission readings. Unique design of Swirling Chamber ensures effective cleaning of lenses. Due to its unique algorithm of time-based accumulation of opacity, the EM919 can give emission per normalized gas volume (i.e. in mg/Nm3) Benefits: In-situ measurement Real time operation High intensity Red LED transmitter which Eliminates error of steam Leads to Effective detection of the ambient light Effective detection of stationary dust on the lens Single pass diverging beam Immune to minor alignment variations State-of-the-art microprocessor technology Reading in mg/Nm3 Calibration check for every reading Maintenance alarm if excessive dust coating on lenses. Hermetically sealed enclosures for the electronics High pressure blowers to keep the lenses clean

...moreBe first to Rate

Rate ThisOpening Hours