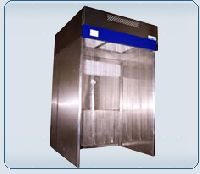

Powder Dispensing Booth

90,000 - 225,000 Per Piece

1 Piece (MOQ)

Powder Dispensing Booth

125,000 - 350,000 Per Piece

1 piece (MOQ)

For mixing, weighing & dispensing of powder. The reverse flow scavenging pre-filter at the work level ensures that aerosolysed particles are picked up at the source without allowing to disperse into the area.

Best Deals from Powder Dispensing Booth

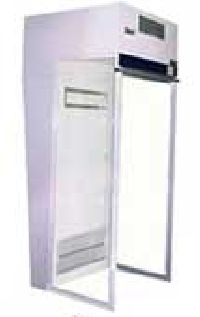

Powder Dispensing Booth

120,000 - 350,000 Per Piece

1 Piece(s) (MOQ)

Equipment is used for dispensing of powder & chemicals to minimize the risk of contaminating of the work area & ensures the health for working person under the laminar air flow. The equipment is based on 3 level of filtration of air circulation. This ensures that the cloud or particles formed by the material dispensed is sucked from the pre filter, intimated filter & supply with mini pleat HEPA filter. Magnehelic gauge will indicate the pressure difference between the filters. During the initial cycle, we achieve class 100 air with velocity 0.45m/s +/- 20% below working area.Features Class 100 air Air curtain effect, Antistatic PVC curtains is provided Internal coving is provided DOP part up stream is provided Mini pleat HEPA filter eff. 99.997% down to 0.3 micron as a supply filter Pre filter eff. 95% Intermediate filter efficiency 90% Electric Motor with high capacity blower FRP blower with aluminum impeller dia 7"x41/2" Electrical supply 3 phase, 415 volt, 50Hz Velocity 0.45m/s +/-20% below working area Antistatic PVC curtains [optional] 10% of the air will throw out with Hepa filters. Feather Touch buttons for on off the Aux. socket & machine

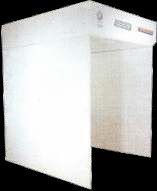

powder containment booth

Get Price Quote

Powder Dispensing Booth

Get Price Quote

Powder containment booths are used to control the hazardous emissions of powders, dust or vapors during powder dispensing, product sampling, or bag dispensing, etc., without risk to the operator or environment. The downdraught prevents airborne dusts caused by weighing and dispensing operations rising into the operator's breathing zone. The air forced downwards is extracted at low level into the booth's filtration system where dust particles are contained at each level of filtration prior to being re-circulated back into the booths' air stream.

Powder Containment Booths

Get Price Quote

Whitenair Technologies offers an ideal enclosure for Pharmaceutical handling by providing high quality Powder Containment Booth. Powder Containment Booth offers many benefits of modular clean room and biological safety cabinet, including a filtration system that maintains cleanliness level of ISO3/ISO 5. Powder Containment Booth offered by us is widely appreciated for providing excellent purity testing, Weighing, Packaging, Chemical analysis. Whitenair Powder Containment Booths available in 304/316 stainless steel or powder coated Steel.  Features : Recirculation Module creates a HEPA Filtered Clean Zone Rear mounted air vents draw air and powder away from operator and work area Rear manifold recalculates air through inlet HEPA filters to ensure a continuous wash of particle-free air to the work area Air conditioning and dehumidification modules maintain precise environmental condition Broad access area, with parting vinyl strip shields, allows easy access, even pallet loading of large containers Whitenair Powde containment rooms features a versatile air-handling system that lets you configure the working space for your requirements. Neutral pressure room : 100% Air Recirculation, Configured as a neutral pressure room, this system ensures 100% recirculation system of exhausted air and complete protection of the external environment Positive Pressure Room : This additional protection optimizes protect purity by controlling airborne aerosols, microbes and other submicron particles Negative Pressure Room : Exhaust Ventilation, for additional protection of personnel inside the room, the Clean Zone Recirculation system let you adjust the percentage of air recirculation into the Containment room.

Powder Dispensing Booths

130,000 - 250,000 Per 1

1 1 (MOQ)

Powder Dispensing Booth

Get Price Quote

The Raw materials and compounds are refilling, weighing, filling, and sampling. It is provided with high efficiency HEPA filter, which averts the airborne dusts by down flow of air technique. The unit eliminates powder contamination to protect the operator and the surrounding environment.The weighing room is one kind of clean equipment which used in micro-organism research, pharmacy and scientific experimentation, it can supply the single and multi-way airflow, and clean air (HEPA AIR) will be circulated in the working area, the other part will be exhaust outside, it can make the working area negative pressure to prohibit cross population, it can guarantee the working area with high clean grade.

Powder Dispensing Booths

Get Price Quote

powder containment booth

Get Price Quote

Immunotech” The manufacture of oral solid dosage forms such as tablets is a complex multi-stage process under which the starting materials change their physical characteristics a number of times before the final dosage form is produced. Traditionally, tablets have been made by granulation, a process that imparts two primary requisites to formulate: compatibility and fluidity. Both wet granulation and dry granulation (slugging and roll compaction) are used. Regardless of whether tablets are made by direct compression or granulation, the first step, milling and mixing, is the same; subsequent steps differ. Numerous unit processes are involved in making tablets, including particle size reduction and sizing, blending, granulation, drying, compaction, and (frequently) coating. Various factors associated with these processes can seriously affect content uniformity, bioavailability, or stability. Sampling/Dispensing is the first step in any pharmaceutical manufacturing process. Sampling/Dispensing is one of the most critical steps in pharmaceutical manufacturing; as during this step, the weight of each ingredient in the mixture is determined according to dose. Dispensing may be done by purely manual by hand scooping from primary containers and weighing each ingredient by hand on a weigh scale, manual weighing with material lifting assistance like Vacuum transfer and Bag lifters, manual or assisted transfer with automated weighing on weigh table, manual or assisted filling of loss-in weight dispensing system, automated dispensaries with mechanical devices such as vacuum loading system and screw feed system. Issues like weighing accuracy, dust control (LAF booths, glove boxes), during manual handling, lot control of each ingredient, material movement into and out of dispensary should be considered during dispensing. Immunotech” The manufacture of oral solid dosage forms such as tablets is a complex multi-stage process under which the starting materials change their physical characteristics a number of times before the final dosage form is produced. Traditionally, tablets have been made by granulation, a process that imparts two primary requisites to formulate: compatibility and fluidity. Both wet granulation and dry granulation (slugging and roll compaction) are used. Regardless of whether tablets are made by direct compression or granulation, the first step, milling and mixing, is the same; subsequent steps differ. Numerous unit processes are involved in making tablets, including particle size reduction and sizing, blending, granulation, drying, compaction, and (frequently) coating. Various factors associated with these processes can seriously affect content uniformity, bioavailability, or stability. Sampling/Dispensing is the first step in any pharmaceutical manufacturing process. Sampling/Dispensing is one of the most critical steps in pharmaceutical manufacturing; as during this step, the weight of each ingredient in the mixture is determined according to dose. Dispensing may be done by purely manual by hand scooping from primary containers and weighing each ingredient by hand on a weigh scale, manual weighing with material lifting assistance like Vacuum transfer and Bag lifters, manual or assisted transfer with automated weighing on weigh table, manual or assisted filling of loss-in weight dispensing system, automated dispensaries with mechanical devices such as vacuum loading system and screw feed system. Issues like weighing accuracy, dust control (LAF booths, glove boxes), during manual handling, lot control of each ingredient, material movement into and out of dispensary should be considered during dispensing.

Powder Dispensing Booth

Get Price Quote

POWDER DISPENSING BOOTHS (Also called POWDER CONTAINMENT BOOTHS) protects the operators from toxic chemicals raw materials used for manufacturing of tablets, medicines, capsules etc from external contamination during the process of weighing or measuring.

Powder Dispensing Booth

Get Price Quote

Our organization has gained recognition as one of the distinguished manufacturers, exporters and suppliers of a broad gamut of Dispensing Booth. The components use in the fabrication process of this booth is of exceptional quality and sourced from the certified and reliable vendors of the market. This booth is widely used to dispensing Bulk Powder, sampling and weighing small quantities of highly active materials. This booth is also designed to control the hazardous emission of powder dust during powder dispensing process. Furthermore, our offered Dispensing Booth is examined upon various parameters of quality to seek out any possible defect.

Powder Dispensing Booth

140,000 - 150,000 Per Piece

Powder Dispensing Booths

Get Price Quote

Powder Dispensing booths are used to control the hazardous emissions of powders, dust or vapors during powder dispensing, product sampling, or bag dispensing etc., without risk to the operator or environment.

Powder Containment Booths

Get Price Quote

we offer powder containment booths. Cleanair™ make powder containment booths are used to control the hazardous emissions of powders, dust or vapors during powder dispensing, product sampling, or bag dispensing, etc., without risk to the operator or environment. The downdraught prevents airborne dusts caused by weighing and dispensing operations rising into the operator's breathing zone. The air forced downwards is extracted at low level into the booth's filtration system where dust particles are contained at each level of filtration prior to being re-circulated back into the booths'' air stream. Powder containment booths cleanair™ make powder dispensing sampling booths are designed to give mixed air flow stream for product, operator and environmental protection and used to control the hazardous emissions of dust powder during powder dispensing sampling process. 0.3 micron downward air stream deflects air-borne dust away from the operator breathing zone which is caused in handling operation. Dust particle available is being filtered at three levels of filtration prior to being circulated back to the booths air stream. For filling, refilling, weighing & sampling of raw material & components

Powder Dispensing Booth

Get Price Quote

Powder Dispensing Booth

Get Price Quote

Dispensing Booths with its open-fronted design, this type of system affords comfort of access for product, operator and environment. Reverse laminar flow powder dispensing booths (Also called powder containment booths) protects the operators from toxic chemicals raw materials used for manufacturing of tablets, medicines, capsules etc from external contamination during the process of weighing or measuring. It is ideal where a high degree of flexibility is desired. Containment is achieved by air movement. Our down flow booths are workstation are available in a variety of air-handling models. When the Booths is operating under normal conditions air is pulled through the main working chamber to exhaust grills, normally situated in the rear of the Booths, suppressing air-borne dust away from the operators breathing zone. Down flow Booths and Workstation provide a safe, controlled working environment and are called upon to carry out a wide range of operations.

Powder Dispensing Booth

Get Price Quote

The Powder Dispensing Sampling Booths are designed to give mixed airflow stream for product, operator, and environmental protection and used to control the hazardous emissions of dust powder during powder dispensing / sampling process. 0.3-micron downward air stream deflects air-borne dust away from the operator-breathing zone, which is caused in handling operation. Dust particle available is being filtered at three levels of filtration prior to being circulated back to the booths air stream. For filling, refilling, weighing & sampling of Raw material & Components.

Powder Containment Booths

Get Price Quote

Mycron Air Tech make Powder containment booths are used to control the hazardous emissions of powders, dust or vapors during powder dispensing, product sampling, or bag dispensing, etc., without risk to the operator or environment.The downdraught prevents airborne dusts caused by weighing and dispensing operations rising into the operator's breathing zone. The air forced downwards is extracted at low level into the booth's filtration system where dust particles are contained at each level of filtration prior to being re-circulated back into the booths air stream. The Powder Dispensing/ Sampling Booths are designed to give mixed air flow stream for product, operator and environmental protection and used to control the hazardous emissions of dust powder during powder dispensing / sampling process. 0.3 micron downward air stream deflects air-borne dust away from the operator breathing zone which is caused in handling operation. Dust particle available is being filtered at three levels of filtration prior to being circulated back to the booths air stream. For filling, refilling, weighing & sampling of Raw material & Components.

Powder Containment Booths

Get Price Quote

Powder Containment booths are used to control the hazardous emission of powder dust during powder dispensingsampling process without any risk to the operator and product as well protecting the environment. The down draught of HEPA filter air prevents airborne dusts caused by handling operation away from the operator breathing zone. The air forced downwards is extracted at low level into the booth's filtration system, where dust particles are contained at three level of filtration prior to being circulated back into the booths air stream.