Y Piece

We are manufacturer and supplier of this product.

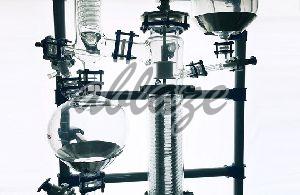

wiped film evaporator

The TFE series Agitated Thin Film Evaporator has proven its efficiency as a device used for the distillation and the evaporation processes, where a scraper system is used to force the process of liquid film-forming. It can successfully undertake several unit operations together, such as defoaming reactions, deodorization, cooling, heating, and much more. Also, you can use it for the recycling process of the organic solvents found from industrial waste. The Agitated Thin Film Evaporator is commonly used in the food industry, pharmaceutical industry, light industry, environmental protection industry, petrochemical industry, and many more. Instrumental Features The scraper system pushes the liquid from a thin film through the rotation process, and hence it provides the appropriate evaporation efficiency and also reduces its operating time. The high-precision pipe made from glass allows the liquid to create a unified thin film over the hot surface. The Scraper system is built of SUS 316L and PTFE; all the other parts that come in contact with the liquid or gas are usually created from high borosilicate glass 3.3 and PTFE, as both the elements have an excellent corrosion resistance properties. The principle evaporation compartment is built from high borosilicate glass 3.3, which allows you to observe the process closely and clearly. You can control the temperature and keep it to the absolute level. The Agitated Thin Film Evaporator can reach up to 260°c temperature. We have a Self-cleaning roller Model film-forming system available with us. You can apply it to TFE-150, TFE-200, and TFE-300 models. We can make the most significant size up to DN300, which can help you reach an effective evaporation area of 0.6 meters Sq. A Self-cleaning roller Model, as well as the Scraper Model film-forming systems, are available with us. We also have Stainless steel material used in manufacturing the distillation barrels. Benefits of Wiped Film Evaporator or Agitated Thin Film Evaporator The Wiped Film Evaporator has a highly specific heat transfer capacity. It has a short residence time. It has a low-pressure drop capacity. It can operate under low vacuum scenarios. It has recorded the evaporation ratios up to greater than 95% without any recirculation. It is highly capable of processing high viscosity products. It is capable of processing the systems that create the deposits. It is super easy to clean. Applications of Wiped Film Evaporator or Agitated Thin Film Evaporator Wiped Film Evaporator can be installed to carry out the evaporation process without any mass transfer. It helps in moderating the evaporation ratios. You can apply or use the Wiped Film Evaporators for the viscous products. You can use it to feed the streams that contain solid particles. You can use the Wiped Film Evaporator to attain the high evaporation ratios of almost more than 95%. It can be applied to stripping.

Material : Metal

Application : Food Industry, Pharmaceutical Industry

Color : Blue

Voltage : 220V

Finishing : Polished

Automatic Grade : Fully Automatic

Feature : High Working Efficiency

...more

Wide Bottom Outlet Spherical Vessel

This vessel is used to fit immersion heat exchanger at the botoom.

...more

Vortex Stirrer

This srirrer is used for low viscosity fluid containing small solid particles.

...more

Vent Valve

We are manufacturer and supplier of this product.

Vent Vacuum Valve

We are manufacturer and supplier of this product.

Unequal Tee

We are manufacturer and supplier of this product.

U Bend With Bottom Outlet

We are manufacturer and supplier of this product.

U Bend

We are manufacturer and supplier of this product.

Two Point Digital Temperature Indicator

This instrument is mainly used to monitor the temperature of liquid in a glass vessel and temperature of vapours at reflux divider in a typical glass distillation unit.This instrument consists of a Temperature indicator and two Resistance temperature detectors (RTDS). The instrument works on 230V,50Hz power supply.in a typical glass distillation unit. This instrument consists of a Temperature indicator and a Resistance Temperature Detector (RTD). The instrument works on 230V, 50Hz power supply. This displays the temperature in degree Centigrade in three and half digits of 12.5mm character height.

...more

Tubular Type Sight Glass

We are manufacturer and supplier of this product.

trunkey projects

Ablaze also provides the complete turnkey project with technical know-how, designed, developed, and equipped with all facilities by a company under contract. Bromine Recovery plant: Cold process to hot process .HBr production Plant Sulphuric acid concentration plant Sulphuric acid dilution plant Nitric Acid concentration plant Solvent Recovery plant

...more

Triple Wall Glass Jacketed Reactor

Ablaze is presenting Flexi (Detachable) Transparent Double Jacketed Vessel to maintain the leading position in industry by way of developing indigenously newer products with higher value towards their Mission and to cater the customer via innovation. Salient Features of Jacketed Vessel Vacuum Jacket ensures Transparent insulation. Minimum heat loss. Process visibility. Minimize frost formation for cryogenics operation. Vacuum Jacket & main vessels are detachable ensures Ease of cleaning. No breakages due to thermal expansion. Partial Replacement of any part can be possible reduce the maintenance cost.

...more

Three Neck Bottom Outlet Spherical Vessel

We are manufacturer and supplier of this product.

thin film evaporator

We are one of the corrosion resistant Wiped Film Evaporators Manufacturers based in India. Wiped Film Evaporator is a Thin Film Evaporator and consists of a jacketed glass SS other corrosion resistant pipe section in which is rotating a corrosion resistant PTFE SS other corrosion resistant wiper system with suitable rows of blades supported by suitable bearings. Wiped Film Evaporators give a high wiping frequency and therefore, an optimum renewal speed of the boundary layer, which are pre-requisites for thorough mixing of the liquid film and for high evaporation rates. The Thin Film Evaporators are forced against the evaporator wall by centrifugal force, and this can be varied via the speed of rotation of the drive, depending on the viscosity of the liquid. Function: The roller wiped film system guarantees a uniform, laminar mixing of the thin film on the entire evaporator surface. Due to overlapping of the rollers and wiping on the unheated areas, so-called “dead-zones” are avoided. At the same time, the liquid thin film on the rollers is continuously renewed. This results in a very low residence time of the evaporating feed on the evaporator surface. Build-up or caking of material on the evaporator surface and on the rollers, which might happen with other wiping systems, is completely avoided with the Ablaze designed roller wiped film system All contact Parts are Glass and PTFE. Designed to carry out distillation at high vacuum. Efficient condenser to condense all the vapors at high vacuum. All Flameproof Electricals and Instrumentation. Can be scaled up to 1 Sq. Mt2 Heat transfer area. Optional SCADA Operated system.

...more

Thermometer Pocket

Thermometer pocket is used to put thermometer , where temperature need to be measured.

...more

The Glass Reactor Systems

350,000 - 1,850,000 Per Set

The Glass Reactor Systems is a common term for a type of rector widely used in the process industries. It is used for a variety of process operations such as dissolution of solids, product mixing, chemical reactions, batch distillation, crystallization, extraction and polymerization. Our Glass Reactor systems assurance the best performance in pilot plant, kilo lab and chemical production - for scale up to cGMP manufacturing of APIs and chemicals. Our versatile reactors are connected to nutsch filters, mixing vessels and scrubbers for additional process steps.

...more

Teflon Bush & Teflon Ropes

Teflon Bush & Teflon Ropes Where there is little need for mechanical strength offered lined steel dip pipes, Super Provides Pure PTFE Dip pipes and it can be an ideal low cost solution to introduce liquor into a storage vessel etc.. They are manufactured from paste extruded PTFE flared one end to raised face dimensions to connect between suitable mating flanges. They can be supplied in any length up to 6000mm long and generally available in sizes from ¾” to 6″NB. Entry pipes are often used to protect the bores of glass lined vessels from mechanical damage, being a sacrificial sleeve. We can supply custom sized liners to ensure correct fit in existing nozzles etc. Nozzle Liners can also be supplied to protect nozzles on glass lined vessels to protect from mechanical damage

...more

Support Plate Assembly

If the free cross-sections obtained with the combination of column sections and packing supports are not large enough, then an alternative is to use type APS pipe sections in combination with fixed support plates. Each item comprises the glass supports plate,screwed rod with nuts, flat washers and compression springs and the special backing flange required for the assembly.

...more

Sulphuric Acid Plant

Sulphuric acid is an essential product of the chemical industry, and is deployed in the most several of processes. It is used in many organic processes as a catalytic agent for synthesis processes or to dry gases such as chlor, bromine, or chloromethane, whereas in the fertilizing industry, sulfuric acid is a basic ingredient for the final product. Ablaze deal in two types of Sulphuric Acid Chemical Plant that includes : Sulphuric Acid Concentration plant Sulphuric Acid Dilution plant Benefits of Industrial Sulphuric Acid Plant High product quality is guaranteed, as glass is completely inert to sulphuric acid Available in wide range of concentrations and capacities Simple and easy to operate Operational reliability due to maintenance free in working Corrosion Resistant

...more

Sulphuric Acid Dry HCL Gas Generator

The plant produces dry HCl gas by the process of distillation of 30% hydrochloric acid with concentrated sulphuric acid as entrainer. Feed Sulphuric acid is fed from top to the packed column and feed 30% hydrochloric acid is also fed to the column. Both the acid flow concurrently. HCl gas is generated by mixing of the two liquid acid feeds. The top portion of the packed column acts as a drying zone for the product HCl gas. Condenser / Cooler is provided on top of a column to cool the outgoing HCl gas. Suitable drying section removes final traces of moisture from outgoing HCl gas. The bottom product from the plant is spent Sulphuric acid with 70% strength (with 1-1.5% HCl content). It is cooled in a heat exchanger prior to discharge. All the wetted parts of the system are fabricated from corrosion resistant materials (Glass and PTFE).

Application : Industrial

Voltage : 220V

Automatic Grade : Automatic

Driven Type : Electric

...more

Sulphuric Acid Dilution Plant

Sulphuric acid is a heavy chemical and finds numerous applications in the industry. It is the product of ‘Contact Process’ and commercially available as 98.5% (ww) H2SO4 or stronger in the form of oleum. However, many of the processes and applications utilizing sulphuric acid require weaker acid than this. As a result, dilution equipment is often necessary in order to meet the requirement for this weaker acid. During dilution, considerable heat is generated depending on the extent of dilution desired. The Integral heat of solution of sulphuric acid is plotted in fig.1. The heat liberated sometimes is sufficient to produce boiling of the acid and so, provision is made for the re-circulation of a portion of cooled dilute acid, thus ensuring working at controlled temperature. From the above it will be clear that intimate mixing and efficient heat transfer form the pre-requisites for sulphuric acid dilution unit to avoid excessive temperature and local heating and uniform product concentration. Process Description Metered quantity of sulphuric acid is introduced to a heat exchanger with re-circulation of water through a pump from the tank containing pre-determinant quantity of water. The turbulence created in the heat exchanger ensures both intimate mixing and efficient heat transfer. When desired strength of acid is reached, the contents of the tank are transferred to storage and fresh batch can be started again.

...more

sulphuric acid concentration plant

Sulphuric acid is used in many processes in chemical plants, thus making spent acid quite diluted. Disposing of this spent acid becomes an environmental pollution problem besides a waste of precious resource. The diluted spent acid can be efficiently re-concentrated up to a maximum concentration of 96% (ww) and reused in the main plant process, thus saving the environment and that too by improving the economical bottom line. Thus, sulphuric acid recovery or concentration plant is a fantastic option for high sulphuric acid users in process plants. Concentration of Sulphuric acid is mostly performed under vacuum in order to reduce the operating temperature, especially for high concentrations. We offer turnkey solutions right from know-how & technology, to supply, installation & commissioning. Our plant comprises of equipments wherin the wetted parts are made up of Borosilicate glass 3.3, Fluoropolymers (PTFE, PFA, FEP, PVDF, PP, etc), High Nickel alloys, Graphite & exotic metals (Ta, Ti, Nb, etc.). The plants can be totally automated by PLC or DCS based systems and even integrated with computers (SCADA etc).

...more

Sulfuric Acid Concentration Plant

Sulfuric acid finds its application directly and indirectly in the manufacture of fertilizers, dyes, intermediates, and many others. Commercial Sulfuric acid is typically available as 98% w/w concentration. Several applications of Sulfuric acid involve the use of medium or high concentration acid, which ends up as relatively dilute acid by picking up water from the reaction. This dilute acid may be concentrated to bring it to the desired concentration level and recycled in the process. This takes care of an effluent problem and also, reduces the requirement of fresh make-up acid. Sulfuric acid is highly toxic and corrosive and reacts readily with metals, depending on its strength and operating parameters. Thus, very few Material of Construction are compatible to handle, process and store Sulfuric acid. Thus, special design and special knowledge are required to set up and operate plants handling Sulfuric acid. Ablaze has a long and successful record of design and supply of several Engineered systems for mineral acids. Being manufacturer of Borosilicate Glass equipment, PTFE components and PTFE lined components, Ablaze is well qualified to handle such systems as these are the major Material of Construction used in such systems. Ablaze also has in-house capabilities for Instrumentation and Automation, which is necessary for reliable and safe operation. Custom made designs are offered for Sulfuric Acid Concentration Plant, depending on the initial and final concentrations of acid, heating medium and cooling medium available, etc. The process basically involves boiling of Sulfuric acid to preferentially evaporate water. The process scheme and operating parameters are selected based on several factors like plant capacity, feed composition/ impurities, initial and final concentration, utilities available etc. A typical and generic flow scheme is shown for a Concentration of Sulfuric acid. The actual process scheme is decided based on the above factors Feed Dilute Acid is fed to the Evaporator/ Boiler at suitable operating pressure. The preferentially evaporated water is condensed in a condenser and the condensate collected. Multiple stages and Vacuum operation may be considered depending on final strength, utilities available and the plant capacity. At higher concentrations of acid, proper demister needs to be provided to avoid carryover of Acid Mist

Application : Sulfuric Acid Concentration

Voltage : 380V

Automatic Grade : Automatic

Driven Type : Electric

Material : Steel

...moreOpening Hours