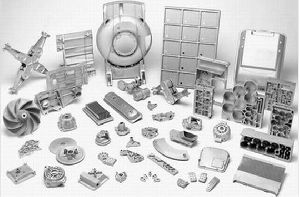

Stainless Steel Investment Casting

By keeping track with the market development, we are offering optimum quality Stainless Steel Investment Casting. These castings are manufactured by our professionals using superior grade raw materials in line with international quality standards. Further, we assure you that our entire gamut is tested on various quality parameters in order to maintain the quality and avoid any flaw. Customers can avail these castings at pocket friendly prices. Maximum Weight of Single Component in Stainless Steel Investment Casting possible is 50kg.

...more

Aluminium Sand Casting

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "Sand Casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries. Over 70% of all metal castings are produced via a sand casting process. Sand casting is relatively cheap and sufficiently refractory even for steel foundry use. In addition to the sand, a suitable bonding agent (usually clay) is mixed or occurs with the sand. The mixture is moistened, typically with water, but sometimes with other substances, to develop strength and plasticity of the clay and to make the aggregate suitable for molding. The sand is typically contained in a system of frames or mold boxes known as a flask. Maximum Weight of Single Component in Sand Casting possible is 120kg.

...more

Aluminium Pressure Die Casting

Pressure casting, also known in manufacturing industry as low pressure casting or pressure pouring, is another variation of permanent mold casting. Instead of pouring the molten metal into the casting and allowing gravity to be the force that distributes the liquid material through the mold, pressure casting uses air pressure to force the metal through the gating system and the metal casting's cavity. This process can be used to cast high quality manufactured parts. Often steel castings are cast in graphite molds using this process. For example, in industry, steel railroad car wheels are cast with this method. Maximum Weight of Single Component in Pressure Die Casting possible is 4kg.

...more

Aluminium Gravity Die Casting

The gravity process begins by preheating the mold to 150-200 °C (300-400 °F) to ease the flow and reduce thermal damage to the casting. The mold cavity is then coated with a refractory material or a mold wash, which prevents the casting from sticking to the mold and prolongs the mold life. Any sand or metal cores are then installed and the mold is clamped shut. Molten metal is then poured into the mold. Soon after solidification the mold is opened and the casting removed to reduce chances of hot tears. The process is then started all over again, but preheating is not required because the heat from the previous casting is adequate and the refractory coating should last several castings. Because this process is usually carried out on large production run work-pieces automated equipment is used to coat the mold, pour the metal, and remove the casting. Maximum Weight of Single Component in Gravity Die Casting possible is 35kg.

...moreBe first to Rate

Rate This