valve Automation

VALVE AUTOMATION SIL 3 certified Advance Valves provides fully integrated and qualified Instrumentation, Electricals and Controls for automated valves. This covers the increasing deployment of automation and controls in every industry, as we specialize in offering solutions to your unique and difficult applications. Gamut of applications covered include:- Motorised Intelligent On/Off application for pipeline, Tankage areas, Plant off-sites and on-sites Pneumatic On/Off application for plant on-sites and off-sites, Tankage area etc. Electro-Hydraulic On/Off application for pipeline and Tankage area etc. Modulating Control Function for Plant onsite and off-sited, pipelines, Tankage area etc. Wired and wireless Remote Operation for any plant and non-plant applications Quick Closing Emergency Shut Down applications for plant and non plant applications With experienced group of engineers and State-of-the-art in-house integration facilities, Advance Valves provides a unique Actuated Valve Value proposition to their clients. This has been made possible because of: A well experienced Automation department committed to optimally design and engineer the integration of valves, actuators and accessories A dedicated shop floor for integration of valve and actuator. Modern automated test beds for actuated valves testing. SIL 3 certified valves, actuators and accessories as required. Strong relationship with qualified global actuator and accessories manufacturers. Excellent track record of supply base of Actuated valves with all type of actuators (Pneumatic, Electric and Electro-Hydraulic). ‘Quality By Habit’ backed with an well established QA/QC program always ensures supply of Quality product to the clients. Excellent track record of actuated valves for all type of actuators – including Electrical, Pneumatic, Electro-Hydraulic.

...more

Screwed End Gun Metal Balancing Valve

The salient features include :- Precise double regulation Tamper-proof setting, with handwheel or lockshield Low flow-noise emission With or without Drain Cocks With or without Pressure Test Cocks Positive shut-off Exceeds IS 778 - 1984 Can eliminate separate Flow Measuring Device. Threaded in Gun metal Construction Sizes upto 3" PTFE Sealing Economy in installation & Operation

...more

Pressure Independent Control Valve

he Pressure Independent Control Valve (PICV) incorporates a small diaphragm type DPCV in order to keep a constant differential pressure across an orifice in order to provide a constant flow rate whilst the differential pressure is with the operating limits of the valve. Beyond these working pressures the valve acts in a similar way to a fixed orifice valve. Salient Features included:- Suitable for Plenty of applications, due to wide range of actuators available. High precision large diameter lockable hand-wheel with simple linear setting scale. The flow rate is adjustable via the hand-wheel even when an actuator is fitted. Full stroke equal percentage temperature control valve gives maximum control under all flow conditions. Reduces capital outlay by eliminating the need for terminal balancing valves, temperature control valves, branch and mains balancing valves, and system differential pressure control valves. The valve has been designed to be easily close coupled to the terminal unit. Selection is simple as no authority calculations are needed. Reduces circuit interactivity. Commissioning is simplified as no costly proportional balance is required. Controllability is made easy due to the equal percentage characteristic. User comfort maximized by ensuring every temperature control valve has full authority. Typical applications of the PICV’s may include:- Fan Coils Chilled Beams (Active and Passive) Radiant Panels and Radiators Heater Batteries Small Air Handling units Heat Recovery Units

...more

Pettinaroli Commissioning Solution

Pettinaroli Commissioning Solution (PCS) The Advance - Pettinaroli Commissioning Solution valve assembly is a new approach to perform the flushing, flow balancing, isolation, and temperature control requirements of individual terminal units.Advance – Pettinaroli Pre-fabricated / Assembled and Tested valve assemblies ensure that everything required for a successful connection is supplied in one package. Furthermore, off-site assembly and testing reduces site time and virtually eliminates costly failures.The Unit is available in Manual/Automatic/Pressure Independent Characterized Control Valves, offering different levels of functionality to meet the needs and budgets of each project. Salient Features:- Push straight onto a FCU and fit directly over a drip tray. Fit with actuators that enable Remote Commissioning and Single Station Balancing. Change the flows whilst the system is in operation. You choose the fittings that come with the valve saving time connecting on site. Have the PCS fitted with strainers and drain plugs, and a PCS unit which acts as a shut off valve and a very accurate flow measuring device if required. Pressure Independent Control Valve Versions eliminate the need for large differential pressure valves on the system; this can save a lot of money. PICV eliminates the need to calculate the two port control valves. Everything required for a successful connection assembly to a terminal unit is supplied in one package. Fewer components to be ordered for each project. Each PCS unit can be tagged and individually identified to each terminal unit. The PCS unit may be orientated in the horizontal or vertical plane on site. The Filterball strainer is easily accessed without drain down. All valves required for commissioning of the terminal unit are in one location. Automatic balancing valves reduce commissioning time to flushing and verification. Pressure independent valves offer full authority temperature control and maximum flow rate limiting.

...more

Low Torque Butterfly Valve

Low Torque Butterfly Valve – BF10R Series Having over 30 years of experience in the designing and manufacturing of Butterfly Valves, Advance Valves has widened its range by offering Low Torque BF10R Series butterfly valves to its range of Concentric, Double Eccentric & the High Performance Triple Eccentric Butterfly valves. Advance Valves BF 10R series is a lightweight low torque butterfly valve, the compact design of which provides excellent structural stability, flow efficiency and effective sealing resulting in prolonged service life and ease of operation. A unique design feature includes a replaceable seat with tongue-and-groove design which provides complete isolation of flowing media from the body at all times. The uniqueness of this specially-designed lining is that the liner is an easy “clip-on” design eliminating the use of any bonding material whatsoever. This feature therefore avoids disbonding between the valve body and the liner which occurs in other valves during operations over time leading to valve-body damage and consequent valve replacement and down time. This valve is ideal for low pressure applications upto 10 bar (150psi). Advance Valves has optimised the requirement for actuated valves solution whereby its full range of rubber-lined concentric butterfly valves are mated to a single-phase electrical operator. This product has a specially designed high induction motor generating a powerful starting torque. The actuator is compact and lightweight and is maintenance-free - truly a fit-nforget solution, additionally eliminating the headaches of actuator-sizing by the end-users. Key Features of Advance Valves’ Low Torque Butterfly Valve Designs available as per API 609, EN:BS 593, IS 13095. Anti-Static & Anti-Blowout features. Low Operating Torque. Wafer body design from 50mm (12”)upto 300mm (12”). Lugged models available on request. Valve Rating of PN10 (150psi). Operating temperatures ranging between -20 ° C to 120 ° C. Bi-Directional Flow with Bubble-Tight Shut-Off. Capable of both On / Off and regulating services. Seat Liner easily replaceable ISO 5211 Operator Mounting Flange. Perfectly mated to a single-phase electrical actuator. Maintenance and trouble free. Design & Performance Features Explained Replaceable Seat to Body Construction: A special replaceable seat with tongue-and-groove design provides complete isolation of flowing media from the body. The sandwiched replaceable seat design eliminates the need for additional line gaskets. Spherical Design of Disc & Seat: The spherical design of the replaceable seat near its contact area with the stem provides primary stem sealing and reduces the seating / unseating torque. This design not only reduces wear and tear of the contact surface of the seat but also provides tight shut-off and excellent regulating characteristics to the valve. Unique Torque-Reducing Design: A specially designed double “D” connection in the upper stem helps to improve the efficiency of torque transfer from the valve operator to the disc. This helps in optimizing actuator selection. Primary & Secondary Stem Seal Design: The stem seal design incorporates a primary seal inherently ensured by interference fit of the soft seat with the disc hub and the secondary sealing is provided by a special double o-ring design which prevents leakages even under adverse conditions. Smooth Operations: The incorporation of heavy duty corrosion-free bushes avoids shaft deflection and minimizes bearing friction. Integral ISO:5211 Mounting Flange: This standardized operator mounting flange is available for assembly of all operators such as hand-levers, gear-boxes, electrical and pneumatic operators further add to ease in operations. Range of Offerings Design Std.: API 609, EN:BS 593, IS 13095.Face-to-Face Dimensions: API 609 Cat. A, EN 558 Sr 20.Size Range: NB 50mm (2”) to 300mm (12”).Pressure Rating: PN 10 (150psi).Temperature Rating: -20°C to 120°C.End Connection: Wafer (Lugged models available on request).Flange Standard: ASME B16.5 #150, ASME B16.1 #125, AWWA C504, JIS OK.Testing: As per API 598

...more

Large Size Balancing valve

Advance Large Size Balancing Valves, a first in the world design by Advance, is a unique Manual Balancing solution for the present trend of large size HVAC and district cooling plants, optimizing space, and integrating all features into a single valve. The valve is designed using state of the art CFD tools validated on in-house flow test bed.ADVANCE Flow Computation Software and System Balancing Software that work with the Hand held digital Manometer are available on request. Advance also provides On-site Water Balancing Services to achieve maximum energy saving right from commissioning The salient features include :- Available in size up to 1000mm (40”). * (Size above 1000 mm available on request.) Precise Double Regulation and Flow Measurement within 2.5D or less Valve Rating PN16 and PN20. *( Pressure PN25 or above available on request.) Positive Shutoff High Performance Butterfly Valve EPDM Seal Stainless Steel construction for critical components Zero Backlash Gear Box with 1 degree accuracy of setting Tamper Proof Locking

...more

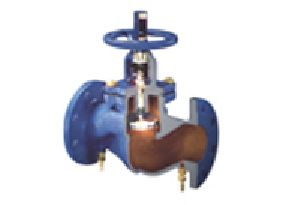

Flanged Balancing Valve

The salient features include :- Precise double regulation Tamper-proof setting, with handwheel or lockshield Low flow-noise emission With or without Drain Cocks With or without Pressure Test Cocks Positive shut-off Exceeds IS 778 - 1984 Can eliminate separate Flow Measuring Device. Flanged in Cast iron for PN16, Ductile Iron for PN20 Size from 3" upto 12" EPDM for Cast iron Construction. Economy in installation & Operation

...more

Dual Plate Check Valves

Advance Valves, is an ISO 9001:2008 accredited and CE certified manufacturer of Dual Plate Check Valves with design features as per API 594 and API 6D Standards. Our Dual Plate Check Valves is multi-purpose Non Slam Zero Velocity, Non-return valve, much stronger, lighter than the conventional Swing Check Valve. Sizes from 2” to 80” diameter. ANSI Class 125 to ANSI Class 2500. API 6A valves ranging from API 5000 to API 10000. Suitable for -196° C (Cryogenic) to 900° C (Fire Safe applications). Soft Seated and Metal to Metal Seated. Fugitive Emission Free Retainerless Design. Models: Wafer, Double & Mono Flanged, Lugged & Sold Lugged, Butt Welded & Hub Ended, Extended Flanged Body, Jacketed Bodies, Ring Type Joints (RTJs) and Cladded. Optimum Spring Design for more than 1 million cycles. Zero Velocity Non Slamming Characteristics. No Valve - Induced Water Hammer Effect. Standard compliance with API 594, 598 & 6D, BS 6364, API 6FA amongst others.

...more

Concenteric butterfly valve

Advance Butterfly Valve are designed & manufactured to have optimum mix of structural stability, flow efficiency & effective seating coupled with advantage of light weight, compact design and ease of operation. Only a quarter turn is needed to fully open or close the valves. The salient features include :- Fit n Forget' Butterfly Valve – internally molded liner 2” to 24” Upto ANSI # 150 From – 50° to 205° C End connection in Wafer, Lugged & Flanged Models Lining and metallurgy to suit a wide variety of applications, including sea water & water desalination plants Seal type (EPDM, Buna N, Viton) Standard compliance with API 609 & 598

...more

Filter Ball Valve

The Filterball is a corrosion resistant isolating ball valve containing an easily interchangeable strainer. This single valve in a compact space provides both isolation and easily maintainable protection of downstream plant and equipment.Where strainers are required DN15 - DN50 a Filterball combined quarter turn isolation valve and strainer should be used. Strainer is mounted within ball and is accessible for maintenance and cleaning when valve is isolated. No upstream and downstream isolation valves are required. Manufactured from Hot forged DZR ,triple sealed blow out proof stem with 2 O-Rings and virgin PTFE packing gland. Interchangeable accessories and fittings such as the steel or aluminium levers and spindle extensions have been designed so that they can be substituted as required. Double body connection seal: to guarantee absolute safety there is a double seal held with Locite and a mechanical seal. A PTFE seal and of two ‘O’ rings provide a triple safety stem seal for guaranteed protection. Ballvalve with integral filter easy to inspect and clean made of Corrosion Resistant brass alloy CW602N, threaded ends. Stem with triple safety (2-O-Rings, PTFE ring), fitted from inside to prevent tampering extraction or bursting. Double tightening in the joint between body and end-connection. Stuffing box movable. Solid spheres are made using diamond tools and chromium plated to the required thickness. Reversible handle. Automatic cleaning device, with back flush feature.

...more

axial check valve

Axial Check Valve – NZ Series Having over 30 years of experience in the designing and manufacturing of NRV’s, Advance Valves has developed the NZ Series of axial or nozzle check valves deploying advanced 3-D design software including Computational Fluid Dynamics analysis as well as thorough testing of the valve prototypes. These valves are widely used in different industry sectors including that of oil and gas such as top site offshore platforms, subsea, refineries, pipelines, LNG and petrochemical plants. Advance Valves’ NZ-Series is an axially operated non-return valve with non-slam characteristics. This valve series incorporates an efficient design with high flow rates and a low pressure-drop, thereby ensuring a high degree of reliability in operations. With these characteristics these valves can safely be used for critical process applications involving process pumps and compressors where equipment safety largely depends on efficient nonreturn valve performance. The axial check valves are mostly installed downstream of rotating equipment to protect the expensive mechanical equipment from possible damages due to backflow. Although they are usually more expensive to other types of check valves, these valves provide safe protection of costly rotating equipment. Many natural gas companies and other power industries are now placing their pipelines below ground and are looking for a one-piece valve they can weld in and bury. The NZ Series Check Valve answers that demand with a precision nozzle-style valve that uses axial-flow technology to eliminate turbulence and prevent erosion and vibration. This design reduces downtime and maintenance costs and boosts capacity and accuracy. Additionally, the NZ Series Check Valve provides a critical service to the power industry due to the valve’s enhanced leak proofing under high pressure thereby virtually eliminating acid and chemical leakage. Key Features of Advance Valves’ Axial / Nozzle Check Valves Designed as per ANSI B16.34. Non-slam, axially operated. Self-operated, no external force required. High flow coefficient, low pressure drop. Quick response to change in flow direction. Metal seated, efficient tight shut-off sealing. Double Flange Body design as standard, other end connections available. Zero emission. Maintenance-free.

...moreBe first to Rate

Rate ThisOpening Hours