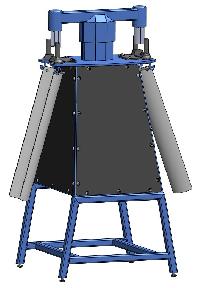

Super Jumbo Total Heavy Double Mill with Cane Carriers

6,125,000 Per Set

We are the main supplier of this product.

rattan wicker

220 - 250 Per Kilogram

100 Kilogram (MOQ)

Best Deals from Cane Mills

Sugar Cane Mill

Get Price Quote

We deal in complete sugar cane mill that is designed, manufactured and installed on a turnkey basis. The sugar plant projects have a wide range and have sugar cane as raw material base. We undertake manufacturing, exporting and supplying of various types of sugar cane mills having complete cogeneration capacity. optimum capacity : 100 tcd to 1000 tcd (tons of cane crushing per day) types of projects : open pan sulphitation, sugar plant.sugar cum jaggery plantopen pan type pressure boiling sugar plantvacuum pan sugar plant what we offer : cane preparation devices : swing knife cane cutter, leveler, chopper, fibrizor, shredder etc.mill house equipment : cane unloader, cane crusher with head stock, crown pinion, groove roller, coupling box, tail bar, trash turner beam, trash plate, bearing housing, top & side cap.conveyors : cane carrier, rake type cane carrier, rake type intermediate carrier, bagasse donnelly shute, bagasse carrier, return bagasse carrier etc.clarification, evaporation and boiling equipment : juice heater, clarifier, sulphur burner, continues sulphitor, mol tanks, lime classifier, evaporator body, vacuum pan, rotary vacuum filter etc.curing and crystallization equipment : air cooled, water cooled & vacuum crystallizers. Continuous automatic and semi automatic & manual batch type centrifugal machine.sugar handling equipment : dryer, hopper, elevator, sugar grader etc.complete fabrication at site : all types of stainless steel, mild steel fabrication i.e. Boiling house supporting structure, mill service gangway, all tanks etc as per clients' requirement. salient features : highly efficientqualitative production like white sugarhigh capacityfully automatic plant (right from unloading of sugar cane to sugar bagging house)vacuum pan sugar plants fitted with captive power generation steam turbine and boilerno extra input for generating power is needed as steam generated from bagasse boiler runs the turbines while the exhaust steam is used in process needs advantages in setting up a sugar project plant : minimum investmentlow operational costno marketing required as sugar is an essential commoditytechnical up gradation takes place every years, making the machines more resourceful and less dependant on labor force

Sweet Sorghum Cane Crusher Mill

100,000 Per Piece

The Sorghum Crusher Mills consists of three roller mills, grooved rollers with under feed toothed roller and Donnelly type chutes for feeding of fiberized cane to Mill.The roller would be of coarse grain cast iron .The cast iron shell would be hot shrunk on forged steel shaft .All the shafts would have square ends of square. The bottom roller would be provided with the juice rings and removable guards to prevent entry of juice into the bearings. The cast steel crown pinion is keyed to shaft and suitable mild steel guard and troughs provided. The bracket for roller bush bearing would be of cast steel with gun metal bush with water cooling arrangements.The mills are provided with cast steel trash plate supported on heavy steel brackets with pivoted journals & adjustable by means of tie rods. Top roller and discharge roller scrappers would be of floating type secured on square shaft and provided with lever for adjusting device. Each mill would be provided with hydraulic loading systems, consisting of hydraulic accumulator, one for each of the journal for the top roller and accessories such as pumping set, receiver tank, gauges.One forced feed oil lubricator for each mill having 16 no. of points is provided so as to have 2 points for each bearing, one bearing as standby. Juice trough under the mills is provided of SSDetails Toothed under feed roller :Toothed type under feed roller having nominal diameters, would be provided. The shaft would be of EN 8 quality & supported by means of bush bearing. The under feet roller would be driven by top rollers through chain sprocket to give surface speed Donnely chute : Each Donnely chute is provided to feed the Each Mill at a suitable height . Slat type intermediate carriers : Rake type / slat type intermediate carriers, between the mills would be provided. The width of the carrier truck would be suitable to accommodate Each carrier drive would consist of one motors with speed reducer, flexible coupling, common bed frame & a set of open sprockets & chains with guards Mill Drive: Suitable electric motors provided to drive the Mill separately Mill Gearbox: Suitable Planetary gearboxes provided to drive each mill separately. Each mill drive to be coupled through CI . The mill top roller would be connected to transmission gear shaft by means of forged steel tall bar and CI couplings.Two cast Iron coupling would be provided.

sugar cane crushing mill

Get Price Quote

1 Set(s) (MOQ)

We are offering sugarcane sorghum crushing mill. Diamond engineering works has been a cherished name in the field of sugar plant across the length and breadth of india. the company manufactures a complete sugar plant with wide range of sugarcane crushing capacity from 50 tcd to 2000 tcd. Our complete range of products are- cane carrier, cane kicker(cutter), cane fibriser, crushing mill with gear box, rake type or slat type inter carrier, grpf & trpf, bagasse carrier, boiler crystallizers, centrifuges, boiling house equipments - evaporating pan, juice heater,concentrator, juice clarifier, juice pumps, air blower, sugar house equipments- sugar drier, sugar grader, sugar packing machine etc.

Cane Crusher Mills

Get Price Quote

Cane Crusher Mills process the cane fed between rollers for facilitating crushing and extraction of juice for further processing. The whole system comprises series of individual mills put together for forming milling tandem as per the capacityefficiency of extraction required.

Roller Cane Mill

Get Price Quote

We are offering roller cane mill. 3 rolar cane mill.

cane mills

Get Price Quote

Cane mills is a well tested module running successfully in major Sugar Mills in India since 1999. The main advantage offered by OraCane is the fast performance and large throughput that is offered by it within no time despite of the large distance covered by it. These features are highly appreciated and certified by all the clients who have experienced the working of the software in sugar environment. The other main advantage of the software is its reliability and high level of automation.

Cane Crusher Mills

Get Price Quote

We offer cane crusher and mill tandems is used in the process, which involves feeding of cane between rollers to facilitate crushing and extraction of juice for further processing. The process involves cane stalks being fed to main cane carrier from where it passes through series of cane cutters for chopping cane into fibers and its further processing using fiberizer (for shredding cane into fine fibers and dropping them to belt conveyor), rake carrier (for conveying fine chopped cane fibers) and others.

Sugar Cane Mill

Get Price Quote

we are looked upon as one of the reliable industrial sugar cane mill supplier in india. The unmatched quality and unsurpassable performance has played a vital role in the enhancement of the demands of sugar cane mill. The sugar cane mills ranging from 10” x 14” to 24” x 24” milling tandem size has been ideally designed to crush 300 t of cane to 1500 t cane per day. Moreover, manual sugar cane mill was initially equipped with pressure feeding devices like grpf orand trpf that further led to increase in grinding rate

cane mills

Get Price Quote

cane mills, Sugar Plants, Boilers, Steam Generators, turnkey sugar plants

cane mills

Get Price Quote

cane mills

cane mills

Get Price Quote

cane mills

Cane Crusher Mills

Get Price Quote

Cane Crusher Mills, Vacuum Pans, cement plants, Kiln Shell

cane mills

Get Price Quote

cane mills

cane mills

Get Price Quote

cane mills

High Performance Cane Mills

Get Price Quote

High Performance Cane Mills, CNC Lathes Slant Bed, CNC Lathes Flat Bed

cane mills

Get Price Quote

cane mills

cane mills

Get Price Quote

cane mills

cane mills

Get Price Quote

cane mills