THROUGHFEED STACKING MACHINE

INTRODUCTION : The new BUKE Through Feed Staking machines are designed to meet the requirements of the present tanning industry, the machine are suitable for staking of all types of leather. MACHINE CONSTRUCTION : The frame unit is extremely rigid & single piece fabricated structure which can take the load of heavy staking operation. STAKING EFFECT The Machines are designed to give better staking effect on the all the parts of leather from belly to butt.

...more

THROUGHFEED BUFFING MACHINES

INTRODUCTION BUKE Hydro pneumatic throughfeed buffing machines are designed to meet the stringent quality requirements of modern tanning industry. The machines are suitable for buffing of leather on both the grain and flesh sides. The machines are robust in construction and easy to operate eventhough they are sensitive and accurate. Details of experience in manufacturing tannery machinery and sound technology backed up by prompt after sales service will guarantee a highly productive machine with superior quality and longer life. MACHINE CONSTRUCTION The frame unit is extremely rigid and is constructed of two side frames of graded Cast Iron joined by a fabricated steel base and two support beams. This frame unit forms a rigid structure for mounting of all the assemblies over it and eliminates any chance of vibration. BUFFING CYLINDER The buffing cylinder used in this machine is made out of high strength aluminium alloy. It is dynamically balanced on Computerised Balancing machine to avoid any vibration or chatter marks on the leather. Morever it is fitted in precision and sturdy roller bearings to give longer service life. The mechanism in the buffing cylinder is so designed that changing the buffing paper is an easy task for the operator. CYLINDER OSCILLATION MECHANISM The machine is fitted with Cylinder Oscillating Mechanism for better buffing result. The cylinder oscillation mechanism is driven by hydraulic motor and the frequency of oscillation is infinitely variable from 0 to 225 Osc./ min. accordingly to the requirements of the buffing operation. FEEDING THE LEATHER The feed roller is coated with special soft rubber to give better finish on the leather. The feed roller is driven hydraulically using a reduction gear box. Feed speed can be infinitely varied in the range of 0 -25 m /min. Opening and closing of the feed roller is achieved pneumatically ensuring fast operation resulting in more productivity.. HIDE HOLDING MECHANISM The machine is fitted with a pneumatically operated hide blade to hold the leather at the end of buffing operation. This device ensures buffing of total AREA of the leather. SKIN CONVEYOR The Skin Conveyor fitted in the machine can be moved in both the directions i.e. forward and backward enabling the collection of processed skins either on the frontside or backside of the machine. The speed of the Skin Conveyor is infinitely variable from 5 m/min. to 30 m/min. and can be set in accordance with the speed of the buffing operation. The provision of Skin Conveyor facilitates the machine attach to dedusting machine forming a continuous processing. SAFETY Machine is fitted with a pneumatic guard on the front. By touching this guard the feed roller will operate to open position and machine will be brought to a stand still. The main motor is fitted with failsafe electromagnetic brake for added safety. Machine will not start unless the Cylinder cover is properly closed. All driving mechanisms in the machine are provided with metal covers to avoid accidents. All electric motors are having overload relays.

...more

leather shaving machines

HYDRAULIC POLISHING MACHINE

INTRODUCTION The growing importance of polishing in skins finishing and the imperative necessity of accel-rating the production cycles, have determined the always increasing choice and use of Stone-polishing machine in the tanneries.BUKE Hydraulic Polishing machines are designed to meet the requirements of high quality polishing of skins in the tanning industry. Details of experience in manufacturing tannery machinery and sound technology backed by prompt after sales service will guarantee a highly productive machine with superior performance, quality and longer life. MACHINE CONSTRUCTION The machine frame is extremely rigid and vibration proof. It is a completely stress relieved fabricated steel body. It forms rigid structure for mainly the polishing roller stone and woolen felt roller. POLISHING ROLLER : The machine is equipped with world famous 'NAXOS AMBER ROLLER' which is mainly suitable for big grain skins, vegetable mixed or chrome tanned leathers. A very important advantage of the machine is interchangeability of the roller stone and it is possible to interchange the Roller within 10-12 minutes time period. The roller stone is dynamically balanced on Computerised Dynamic Balancing machine which gives absolutely vibration free performance. FEED (WOOLEN BELT) ROLLER : The Feed Roller is made from a good quality woolen felt sleeve to give better polishing effects. The Feed Roller is driven by hydraulic motor along with reduction gear box and feed speed can be infinitely varied in the range of 0 - 25 mtrs/min.The closing and opening of Felt Roller are controlled by hydraulic cylinder which gives a constant pressure and consequently a better polishing result. A special safety clutch is provided to Felt Roller to prevent the damage or spoilage of Felt Roller during the overload. The machine is equipped with an inbuilt centrifugal type exhauster system. SAFETY : a) The machine is fitted with an electo-mechanical guard on the front, by touching thisguard the Felt Roller will operate to open position and machine will be brought to standstill.b) The machine will not start unless the polishing roller cover is properly closed.c) All driving mechanisms in the machine are provided with sheet metal covers to avoid accidents.d) All electric motors are having overload relays.e) The machine is provided with 'emergency off on front operating panel.

...more

HYDRAULIC LEATHER SHAVING MACHINE

INTRODUCTION : Bharat Udyog is manufacturing the Shaving machines in the working widths of 500 mm to 1500 mm. After studying carefully the requirements of the various tanners Bharat Udyog has developed BUKE 1000 mm Shaving Machine for shaving of all types leathers in wet, dry and also blue chrome condition. Its simplicity of operation with extremely rigid construction enables the machine to give high production output with desired quality levels. Decades of experience backed by sound technology and prompt after sales service ensures trouble-free operation and highly productive machine with superior performance, quality and longer life. SALIENT FEATURES : MACHINE CONSTRUCTION : The complete frame structure of the machine is made of graded cast iron with sufficiently thick and well ribbed section. This assures extreme rigidly of construction which eliminates any chance of vibration mark on leather even under heaviest cut. KNIFE CYLINDER : The Knife Cylinder is made from high strength forged steel and rotates in a heavy duty ball bearings with grease lubrication and dynamically balanced to ensure chatter free operation. The standard cylinder is fitted with 10 LH and 10 RH blades. FEED ROLLER : The feed roller is driven by a hydraulic motor with reduction gear box and feed speed can vary from 0 to 20 meters/min. The opening and closing of feed roller is accomplished by precision cam operated mechanism driven by hydraulic cylinder which enables accurate leather thickness even under heaviest cut load. All the links and mechanisms involved are having ball bearings / roller bearings at the joints ensuring friction free movements reducing wear & tear resulting in prolonged machine life.b) Due to the flywheel effect of the main shaft at high speed, the power required is less than equivalent machines. This leads to low power consumption at the same output. GRIP ROLLER : The facility of grip roller enables easy feeding of leather and avoid'wastage of leathers because of cutting at folds. Also it reduces the operator fatigue to a great extent resulting in more output. The machine is provided with taper setting attachment to take care of any uneven thickness after shaving the leathers to its full span. ELECTRONIC FINE THICKNESS ADJUSTMENTS DEVICE : The machine is fitted an electronic fine thickness adjustments device which enables the initial, setting to be varied in steps of 0.1 mm. GRINDING MECHANISM FOR KNIVES : The grinder travels on a heavy duty slide with an electromechanical drive. This enables perfect grinding of knives. The feeding of grinding wheel in knives is automatic and no human intervention is required, reducing time required for grinding. SAFETY : All electric motors are provided with overload relays. Grinding feed can not start until the grinding motor is ON. A safety device is provided near the Knife Cylinder which will stop the machine if the operator touches the same accidently. Sheet metal guards are provided whenever necessary.

...more

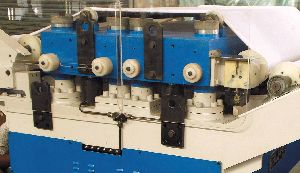

CONTINUOUS VIBRATION STAKING MACHINES

FOREWORD: ' BUKE ' Continuous Vibration Staking Machine has been designed to soften the leather by staking operation. It provides a vigorous mechanical action on the leather and pulling the fibres apart so that they are permanently free from the stresses imparted during previous processes. It also helps in opening and spreading the leather thus enlarging its surface area remarkably. SALIENT FEATURES : 1. FULLY INDIGENOUS The entire machine is designed and developed indigenously at our works only. The complete frame structure is fabricated from graded steel and having high rigidity to withstand against vibrations during staking operation. 2. VERSATILE : The machine can be used for staking any type of leather in its proper condition having the required water content. The thickness of leather must not exceed 3.2 mm. Two pieces of leather upto 1.5 mm thick each, can be feed for staking simultaneously unless they are too stiff. 3. UNIFORM STAKING : After feeding the leather on table and bottom conveyor, it passes through the working area between top and bottom conveyor. The leather is pulled in all directions during staking operation in which the leather is staked in between upper and lower staking pins results in uniform staking effect. 4. ADJUSTABLE STAKING INTENSITY : The intensity of staking can be adjusted by changing the position of upper pin plate with the help of hand wheel provided on the top beams. This arrangement is suitable for staking leathers with different fibre strength, density, thickness and stiffness. 5. INFINITELY VARIABLE CONVEYOR SPEED : The Conveyor belts are driven by a 2 HP heavy duty infinitely variable mechanical speed variator. The speed of the conveyor belts can be varied infinitely from 6 meters / min to 18 meters / min. 6. SAFTY : The operator's safety is carefully ensured by means of following.:a) Guards provided on all driving mechanisms and rotating parts.b) All electric motors are provided with overload relays.c) The machine is fitted with a special device that prevents undesirable objects from entering into the machine. 7. REVERSING FACILITY : As an additional safety, the conveyor is also provided with a facility of reverse rotation if required by the operator in case of emergency.

...more

AIRBLAST DEDUSTING MACHINES

INTRODUCTION BUKE Airblast Dedusting Machines are manufactured in two models AD-130 & AD-180. The machines are designed and manufactured giving careful consideration to the problem of dust in finishing of leather. These Machines can be fitted after Throughfeed Buffing Machines to make a countinuous production system and the speed of the Dedusting Machine can be adjusted in accordance with the speed of Buffing Machine. The high level of technology and sophistication in the machine will guarantee dust free leather required in modern leather finishing processes. SALIENT FEATHERS DEDUSTING HEADS The machine is designed to have two dedusting heads on the top and one dedusting head at the bottom. This arrangement of jets ensures proper cleaning of leather on both the sides. The dedusting heads are carefully designed and manufactured to ensure smooth airflow and easy maintainance and cleaning. COMPATABILITY WITH THROUGHFEED BUFFING MACHINE BUKE Airblast Dedusting Machine can be easily connected to BUKE Through-feed Buffing Machine to give excellent results in the continuous process.It is not necessary that these machines can be coupled only with BUKE machines, but can be joined with any Throughfeed Buffing Machine having conveyor for carrying out processed leather. FEEDING OF LEATHER The leather coming out from Through-feed Buffing Machine will fall on the conveyor of Airblast Dedusting Machine and will be fed to the machine automatically. BUKE Dedusting Machine can be operatedindependently also, which gives flexibility in production. The conveyor speed of dedusting machine can be adjusted from 5 to 25 mtr./min. in accordance with the speed of Buffing Machine. COMPACT RCOTS BLOWERS The machine is operated with special high speed compact roots blower which gives required quantity of air with pressure and minimum noise level. The blowers are having minimum spares to reduce maintenance cost.

...moreBe first to Rate

Rate ThisOpening Hours