horizontal sand mill

Get Price Quote

1 Piece (MOQ)

horizontal sand mill

1,600,000 - 1,700,000 Per Unit

HM Series

Best Deals from Horizontal Sand Mill

horizontal sand mill

700,000 - 1,200,000 Per 1

horizontal sand mill

Get Price Quote

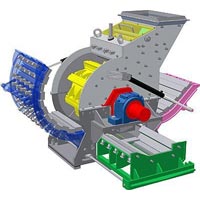

We offer excellent quality Horizontal Sand Mill in the market. These Horizontal Sand Mills are extensively used for producing dyestuff, coating, paint, ink, medicine, sensitive film, magnetic powder, pesticide, cosmetics etc. It consists of grinding container, grinding disc, main shaft, feeding pump etc. as its components. Major parts of this Horizontal Sand Mill are made up of special wear resistance steel. Applications This Series Of Sand Mills Are Efficient Ultra Micro Wet Grinding And Dispersing Machines In Common Use, And They Are Widely Used For Producing Coating, Dyestuff, Paint, Ink, Medicine, Magnetic Powder, Sensitive Film, Pesticide, Cosmetics And Paper Making, And So On. We Use Advantages Of The Same Kind Of Mill In Our Country On These Mills. So These Mills Have High Efficiency, And Can Work Continuously And Have Less Pollution, Its Self-Control Is Dependable. Its Cost Is Low. Its Appearance Is Nice. The Maintenance Is Convenient. Especially These Mills Are Very Practically Useful. Details Model SFDM â�� Having --- Liters Total Volume Capacity Having The Output Of -- to -- Liters Per/Min. This Machine Is Suitable For Grinding Low Medium High Viscosity Material Between 100cpsand 5000CPS Thixotropics And Products With Highly Pigmented System. This Machine Will Have The Following Items : Body : This Machine Will Have The Following Items. Sturdy Mild Steel Heavy Duty Plate Frame Body Of For The Mill. Grinding Container : Double walled Cooling Efficiency Is Enhanced Through The use Of a Two-Zone Spiraled Jacket. The Spiral Design Creates These Desired Effects: cooling to the Entire Chamber; Greater Temperature Control Due To Increased Surface Area; And Reduced Pressure Drop by the Use of Two Inlet and Discharge Ports. Inner cylinder is stainless steel 304 6mm.i and easily exchangeable. Grinding chamber net volume is 20 Ltrs.Grinding Disc : Grinding Disc Available Will Be Of Special Wear-Resistant Steel, Hardened Chrome Steel Discs, Stainless Steel (304 Or 316), Hastelloy C , Polyurethane , UHMW Polyethylene , Polyamide (Nylon).Main Shaft : Main Drive Shaft Will Be Of Stainless Steel 304 Construction.Grinding Container : Double Walled Cooling Efficiency Is Enhanced Through The Use Of A Two-Zone Jacket. Inner Grinding Cylinder Will Be Of Stainless Steel 304 10mm Thick And 3mm Thick Water Cooling Jacket Of Stainless Steel 304. S.F. Pearl Mill Will Have 20/40/60/80/100 Liters Size Of Grinding Cylinder Material Of Construction Stainless Steel 304.To Control Temperature Use Of Chilled Water Is Required.Sealing : Shaft Sealing Is Carried Out By A Single-Action Mechanical Seal With Rotor And Stator Of Tungsten Carbide. Rinsing An Of The Mechanical Seal Is Provided By A Glycerine-Flow Closed Circuit System By A Teflon Lip-Seal, Glycerin Also Water â�� Cooled. Separation for the grinding beads. Scree Type Outlet /or Vee Slot Well Screen For Separation Of Grinding Media From Slurry. Grinding beads size 0.5 to 2.55mm, (It is cautioned not to use beads less than 0.5mm).Feeding Pump : Screw Pump Of Size 1â�� Coupled With Variable Speed Gear Box Or ½â�� size Diapharm Pump â�� M Seal Rinsing Pump ¼ Inch / Centrifugal Type.Agitator Disc Peripheral Speeds : The speeds are 10 / 13 / 16 m/sec, by changing of the motor pulley.Drive : Main motor will be -- HP 1440 RPM, 3ph, 440V, 50Hz of any standard make. Feeding pump is runned and controlled by a 1.5kW -- HP Variable Speed Mechanical Drive Box Having The Speed Range Of 40 â�� 200 Rpm Or Diapharm Pump. Mechanical Seal Rinsing Pump Motor Is 0.18kw.Control Panel : Control panel mounted on the machine body is composed of start-stop buttons for motors; ON_OFF switch and ammeter; emergency stop button; adjustable pressure and temperature units. Materials : Material parts which are subject to wear and tear with the product are made of specific hardened steel and stainless steel. Maintenance : By the easy-fitting front rail system, operations such as; detailed cleaning of the grinding chamber maintenance of and the media can be handled easily, just by unscrewing five nuts. Production Capacity : The capacity of SFDM â�� completely depends on the product to be processed. It may differ between the average v 100 Liters / 300 Liters, but the actual values may vary during the operation. Machine Limiting Values Max. Product Pressure : 3 barMax Product Temperature : 110oCMin. Temp. Of Cooling Water : 25oCMax. Pressure of Cooling Water : 6 barMax. Cooling Water Pressure for Glycerine Vessel : 4 bar

horizontal sand mill

Get Price Quote

Root Laboratory 0.5L horizontal sand mill is specially designed for dispersing and grinding of sub-micron, micron, sub-nano and nano grade material. The high efficient cooling system and fine-gap centrifugal separating system could avoid the block of material in separator and ensure a smooth product discharging. It is specially used in the lab formulation research and small batch production. The lab mill grinding result could be scaled up to the industrial production.

horizontal sand mill

Get Price Quote

Horizontal sand mill is suitable for all kind of products from low to high viscous pump able products for fine grinding with media. The bead mill sand mills are widely used in pint, ink, chemicals, Agro chemical and coating industries for size reduction and dispersing of pigments in liquid, Particle size reduction up to 2.

horizontal sand mill

Get Price Quote

The Sand Mills are mainly used by coating, ink and paint industries for the size reduction and dispersing of pigments in the liquids. The pigment particles are dispersed upto 2 microns in a single pass. The milling chamber is fitted with grinding media, where the feed is pumped from the bottom chamber. The material moves upwards and subjected to high shearing force, which results in finely grinded material. A jacket arrangement is also provided for the cooling of grinding material in the chamber.

horizontal sand mill

Get Price Quote

This Series Of Sand Mills Are Efficient Ultra Micro Wet Grinding And Dispersing Machines In Common Use, And They Are Widely Used For Producing Coating, Dyestuff, Paint, Ink, Medicine, Magnetic Powder, Sensitive Film, Pesticide, Cosmetics And Paper Making, And So On. We Use Advantages Of The Same Kind Of Mill In Our Country On These Mills. So These Mills Have High Efficiency, And Can Work Continuously And Have Less Pollution, Its Self-Control Is Dependable. Its Cost Is Low. Its Appearance Is Nice. The Maintenance Is Convenient. Especially These Mills Are Very Practically Useful.

horizontal sand mill

Get Price Quote

This Series Of Sand Mills Are Efficient Ultra Micro Wet Grinding And Dispersing Machines In Common Use, And They Are Widely Used For Producing Coating, Dyestuff, Paint, Ink, Medicine, Magnetic Powder, Sensitive Film, Pesticide, Cosmetics And Paper Making, And So On.

horizontal sand mill

Get Price Quote

horizontal sand mill The optimum configuration for every poduct with an extremely wide choice of material for parts wetted choice of materials for parts wetted by the product including hardened and stainless steel, hard chrome-plated stainless steel, polyurethane and engineered cermics

horizontal sand mill

Get Price Quote

horizontal sand mill

Get Price Quote

horizontal sand mill, Pin Mill, Bead Mills, Rotary Dryers, Pug Mill

horizontal sand mill

Get Price Quote

horizontal sand mill, Cement Mixer, Water Proofing Chemical Plant

horizontal sand mill

Get Price Quote

horizontal sand mill, Hydroxyethyl Cellulose, Fertilizer Urea