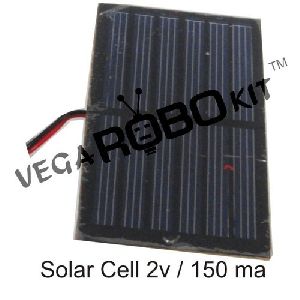

Solar Cells

350 Per Piece

Driven by the passion to provide nothing but the best, we have risen as trusted suppliers of 2V Solar Cell in the market. After the goods are sternly examined by the experts, the picking, checking, labeling and packing commences in the substantial warehouse. Sprawling over a large area, we ensure that the goods are packed with utmost proficiency. The offered Solar Cells are made of high efficiency crystalline silicon; available in the thickness 40mm.

Low Iron Solar Glass

Get Price Quote

2000 Square Meter (MOQ)

Gujarat borosil limited manufactures low iron high transmission textured solar glass at its state-of-the-art manufacturing facility in gujarat state with technology imported from west europe from world leaders of glass equipment. Glass panes are routed through a high quality automatic line for pencil edging and washing before tempering to a very high degree of flatness, designed to keep within tolerances of flatness required by international pv industry in a high speed automatic glass tempering line. the manufacturing facility is iso 9001:2008 accredited from tuv rheinland and product conforms and adheres to various international standards. Gbl has an in-house laboratory fully equipped with the latest and most advanced testing equipment to ensure top quality end product to the customer. Gbl's solar glass is the most technically advanced solar glass in the world, having the following unique features: 1. Durability: in tests conducted in photovoltaik institut ag, berlin, it has proved to be the most resistant glass to pid. ( potential induced degradation )it has the lowest sodium content amongst solar glasses in the world. The hydrolytic resistance is also very high for our glass. Our glass is engineered for long term durability. 2. The anti-reflective coating supplied by us has outstanding performance and durability. We can confirm the source of the liquid supporting it with documentary evidence. light transmission increases by 2 to 2.5% with a single side ar coating through a roller coating process. The ar coating that we use has long term performance durability. 3. At 85 ppm, we have the lowest iron amongst solar glasses in the world. This has been tested by five renowned laboratories from west europe and india. Low iron means better light transmission in solar glass. 4. Performance: our glass has received a glass efficiency value of 0,952 from spf switzerland, which puts it above other glasses which they have tested.

Best Deals from Solar Cell

THICK FILM SCREENS SOLAR CELL

Get Price Quote

We are offering thick film screens solar cell. Hybrid microcircuit solar screens usp's of thick film screens manufactured in technical collaboration with ms. Micro circuit enginneering corporation , u.s.a. consumables , stainless steel mesh, emulsion etc, are imported from overseas suppliers. mesh stretching on imported pneumatic stretching machine. complete thick film screen can be delivered in 4 working days our production, marketing and design department are trained overseas to give you complete soultion for thick film screens. stringent statistical quality control norms. expertise in supplying 'imaged, 'precoated', 'mesh only' screens and frames. uniform coating thickness. range of emulsions for various applications. long print life of screen. screen for fine line resolution printing. custom made frames.

Polycrystalline Solar Cells

Get Price Quote

Low Iron Glass

Get Price Quote

This glass is used for multi and mono crystalline solar photovoltaic modules. The content of iron oxide is significantly lower than in normal flat glass, which gives it a distinctive, nearly colourless appearance particularly when seen from the edge, and makes it a high solar energy transmitting glass. The textured surface helps to diffuse the light and inhibits the reflection of a part of the solar energy back into the atmosphere as compared to a polished surface, thus enhancing solar energy transmission.

Solar Cell

100 Per Piece

Low Iron Solar Glass

Get Price Quote

Solar Glass

100 Per Square Feet

Solar PV cells

Get Price Quote

photovoltaic cells

Get Price Quote

What is photovoltaic effect? Photovoltaic effect is defined as the phenomenon in which the incidence of light upon the junction of two dissimilar materials, as a metal and a semiconductor, induces the generation of an electromotive force. Simply put, photovoltaic effect is the creation of electric current in a material upon exposure to light and is an electro-chemical phenomenon. Having no moving parts – like turbines etc. which are typical of other forms of electricity production- is a unique advantage of photovoltaic power generation. The most common material used to make solar PV cells is Silicon because it shares some of the properties of metals and some of those of an electrical insulator. Photovoltaic cells consist of a positive laver and a negative layer of this material. Let’s take a closer look at what happens when the sun shines onto a solar cell. Sunlight consists of little particles of energy called photons. When this energy in sunlight strikes the silicon based solar cell, electrons are knocked loose from the atoms in the semiconductor material. If electrical conductors are attached to the positive and negative sides, forming an electrical circuit, the electrons can be captured in the form of an electric current -- that is, electricity.

Solar Cells & Modules

Get Price Quote

Customers can avail from us a high quality range of environment friendly Solar Cells & Modules. These Modules offer a stable performance for multipurpose outdoor applications. Manufactured using high quality raw material, these are highly resistant to the severest climatic conditions. We offer an unmatched 25 years warranty on these products for power output. These technologically advanced products feature bypass diodes, which reduce the power loss caused by shade. The modules use high efficiency 125 mm square mono-crystalline silicon solar cells with over 14% module conversion efficiency. Material Monocrystalline SiliconPolycrystalline SiliconAmorphous Silicon Photovoltaics: Solar Electricity and Solar Cells in Theory and Practice The word Photovoltaic is a combination of the Greek word for Light and the name of the physicist Allesandro Volta. It identifies the direct conversion of sunlight into energy by means of solar cells. The conversion process is based on the photoelectric effect discovered by Alexander Bequerel in 1839. The photoelectric effect describes the release of positive and negative charge carriers in a solid state when light strikes its surface. How Does a Solar Cell Work? Solar cells are composed of various semiconducting materials. Semiconductors are materials, which become electrically conductive when supplied with light or heat, but which operate as insulators at low temperatures. Over 95% of all the solar cells produced worldwide are composed of the semiconductor material Silicon (Si). As the second most abundant element in earth`s crust, silicon has the advantage, of being available in sufficient quantities, and additionally processing the material does not burden the environment. To produce a solar cell, the semiconductor is contaminated or "doped". "Doping" is the intentional introduction of chemical elements, with which one can obtain a surplus of either positive charge carriers (p-conducting semiconductor layer) or negative charge carriers (n-conducting semiconductor layer) from the semiconductor material. If two differently contaminated semiconductor layers are combined, then a so-called p-n-junction results on the boundary of the layers. At this junction, an interior electric field is built up which leads to the separation of the charge carriers that are released by light. Through metal contacts, an electric charge can be tapped. If the outer circuit is closed, meaning a consumer is connected, then direct current flows. Silicon cells are approximately 10 cm by 10 cm large (recently also 15 cm by 15 cm). A transparent anti-reflection film protects the cell and decreases reflective loss on the cell surface. The usable voltage from solar cells depends on the semiconductor material. In silicon it amounts to approximately 0.5 V. Terminal voltage is only weakly dependent on light radiation, while the current intensity increases with higher luminosity. A 100 cm² silicon cell, for example, reaches a maximum current intensity of approximately 2 A when radiated by 1000 W/m². The output (product of electricity and voltage) of a solar cell is temperature dependent. Higher cell temperatures lead to lower output, and hence to lower efficiency. The level of efficiency indicates how much of the radiated quantity of light is converted into useable electrical energy. Different Cell Types One can distinguish three cell types according to the type of crystal: monocrystalline, polycrystalline and amorphous. To produce a monocrystalline silicon cell, absolutely pure semiconducting material is necessary. Monocrystalline rods are extracted from melted silicon and then sawed into thin plates. This production process guarantees a relatively high level of efficiency. The production of polycrystalline cells is more cost-efficient. In this process, liquid silicon is poured into blocks that are subsequently sawed into plates. During solidification of the material, crystal structures of varying sizes are formed, at whose borders defects emerge. As a result of this crystal defect, the solar cell is less efficient. If a silicon film is deposited on glass or another substrate material, this is a so-called amorphous or thin layer cell. The layer thickness amounts to less than 1µm (thickness of a human hair: 50-100 µm), so the production costs are lower due to the low material costs. However, the efficiency of amorphous cells is much lower than that of the other two cell types. Because of this, they are primarily used in low power equipment (watches, pocket calculators) or as facade elements. Level of efficiency in % Lab approx. 24approx. 18approx. 13 Level of efficiency in % Production 14 to1713 to155 to7 From the Cell to the Module In order to make the appropriate voltages and outputs available for different applications, single solar cells are interconnected to form larger units. Cells connected in series have a higher voltage, while those connected in parallel produce more electric current. The interconnected solar cells are usually embedded in transparent Ethyl-Vinyl-Acetate, fitted with an aluminum or stainless steel frame and covered with transparent glass on the front side. The typical power ratings of such solar modules are between 10 Wpeak and 100 Wpeak. The characteristic data refer to the standard test conditions of 1000 W/m² solar radiation at a cell temperature of 25° Celsius. The manufacturer's standard warranty of ten or more years is quite long and shows the high quality standards and life expectancy of today's products. In addition to optimizing the production processes, work is also being done to increase the level of efficiency, in order to lower the costs of solar cells. However, different loss mechanisms are setting limits on these plans. Basically, the different semiconductor materials or combinations are suited only for specific spectral ranges. Therefore a specific portion of the radiant energy cannot be used, because the light quanta (photons) do not have enough energy to "activate" the charge carriers. On the other hand, a certain amount of surplus photon energy is transformed into heat rather than into electrical energy. In addition to that, there are optical losses, such as the shadowing of the cell surface through contact with the glass surface or reflection of incoming rays on the cell surface. Other loss mechanisms are electrical resistance losses in the semiconductor and the connecting cable. The disrupting influence of material contamination, surface effects and crystal defects, however, are also significant. Single loss mechanisms (photons with too little energy are not absorbed, surplus photon energy is transformed into heat) cannot be further improved because of inherent physical limits imposed by the materials themselves. This leads to a theoretical maximum level of efficiency, i.e. approximately 28% for crystal silicon.

Solar Cells

1,500 Per Piece

Solar PV cells

Get Price Quote

Solar PV cells, Solar Rooftops, Solar Outdoor Lighting

photovoltaic cells

Get Price Quote

photovoltaic cells, spv modules, Solar Power Packs, wind energy

solar photovoltaic cells

Get Price Quote

We are offering solar photovoltaic cells.

Photovoltaic Cell

Get Price Quote

Photovoltaic Cell

Silicon Photovoltaic Cell

Get Price Quote

Silicon Photovoltaic Cell, bi-mwa light scattering detectors

photovoltaic cells

Get Price Quote

Photovoltaic effect is defined as the phenomenon in which the incidence of light upon the junction of two dissimilar materials, as a metal and a semiconductor, induces the generation of an electromotive force. Simply put, photovoltaic effect is the creation of electric current in a material upon exposure to light and is an electro-chemical phenomenon.

Solar Cells and Modules

Get Price Quote

Solar Cells and Modules, Solar LED 5 Watt Bulb With Battery

Solar Cell

Get Price Quote

Solar Cell, multi functional devices, Printer, Scanner, Lcd Monitors

Solar Cells

Get Price Quote

Solar Cells, Solar Water Heaters, Solar Lantern, Solar Lighting Systems

Solar Cell

Get Price Quote

Solar Cell, Fuel Cell, pc board assembly line

Solar Glass

Get Price Quote

Solar Glass, Mini CD

Low Iron Solar Glass

Get Price Quote

Low Iron Solar Glass

Solar Cell

Get Price Quote

Solar Cell, dry cells

Low Iron Solar Glass

Get Price Quote

Low Iron Solar Glass, pizza plate