Waste Heat Recovery System

Get Price Quote

These are custom built equipments as per the type waste heat available and the process heat requirements. A detailed study of the clients system is required. These systems can be designed to recover waste heat from high temperature flue gases of furnaces, DG sets, boilers or any other heat source. The waste heat can be converted into hot water, steam, hot oil or hot air as per the process heating requirements.The waste heat recovery can be designed in shell and tube type or water tube type design based on the operating pressure of the system.

Waste Heat Recovery System

Get Price Quote

Wastewater temperature is major form of pollution. In dyeing processes, so much hot water is discharged that, in the absence of any counter-measures, total wastewater temperatures may exceed 40°C, even though 35°C is the maximum permissible temperature. This new regulatory effort comes at a time when textile companies are already faced with the need to reduce costs to respond to increasing competition.

Best Deals from Waste Heat Recovery System

Waste Heat Recovery System

Get Price Quote

We design and manufacture waste heat recovery unit to capture available waste heat for water heating.This hot water can be used for various purposes like-Boiler feed water, process water, to run absorption chillers etc.

waste heat recovery systems

Get Price Quote

Increase in fuel cost and tough competition in automobile sector leads to reduce the vehicle prices inorder to sustain in the market. Cost cutting is the only tool. Main focus in this regard is Paintshop Waste Heat Recovery. Generally the Paintshop Exhaust Flue Gases have high degree (almost 250 °C.) of heat which gets exhausted into the atmosphere. THERMIN ENERGY SYSTEM provides heat recovery system inorder to trap this heat and generate hot water for paintshop use. Thus the fuel to be used for hot water generator gets saved. THERMIN ENERGY SYSTEM provides such systems for about 8 to 10 months payback period.

waste heat recovery systems

Get Price Quote

Waste Heat Recovery Systems With day by day rising costs of fuel & in turn utility cost, recovering the waste energy is a basic need of any process industry. We offer complete customized package solution to recover energy from various waste heat sources in process plants. In any process plant there are many heat sources available which are going to drain/ETP from which substantial amount of energy can be recovered like: Hot contaminated steam condensate, Vent Steam, Dye liquor from textile process, Process drain hot water, Boiler Blow down water & many more…. Benefits of Waste Heat Recovery Systems: Savings of substantial amount of Steam/Fuel. Reduced load on ETP as lower temperature effluent going to ETP. Reduced batch timings as in some cases hot water from the heat recovery system is used as input to the process. Boiler steam output increases as in some cases hot water from the heat recovery system is used as input to boiler feed water tank. Features of Waste Heat Recovery Systems: Compact design & skid mounted Design for ease of maintenance User friendly Performance monitoring tools provided Cost effective Safe in operation Recovering heat from the different sources needs different engineering of the complete system, which involves Selection & designing of: Waste Heat Recovery Systems The selected heat exchanger should be suitable for the particular application The design should be considering the maximum Waste Heat Recovery Systems

Waste Heat Recovery System

Get Price Quote

We offer waste heat recovery system that is technically sound and is easy to install. The waste heat recovery system provided by us uses waste energy resources and converts them into useful ones. These waste heat recovery systems are customized as per the needs of the clients. used for steamlow pressuremedium pressurehigh pressurehot waterpressurizednon pressurized hot air thermic fluidchilling planapplications scrap melting steel furnacesincinerators industrial furnacesprocess waste gasescement kilns.

waste heat recovery systems

Get Price Quote

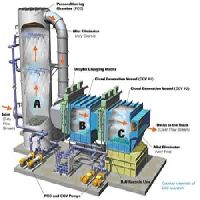

We provide Waste Heat Recovery Systems ( WHRS ) on Natural Gas / Bio Gas /HFO /FO/ HSD based Engines/Turbines and Waste heat coming from different processes like GLASS Furnace exhaust, Melting Furnaces Exhaust, Cement Waste Gases and Steel Furnaces. The huge power cost hike and increase of power demand in industry segment we all has to take each and every chance to trap the waste heat and generate steam possibly for Combined Power Plant or for process steam application. The waste heat recovery project is viable only depending on the investment recovery period. We "THERMIN" are very well known this fact and are designing/manufacturing/supplying the systems which gets maximum possible monetory outputs and in minimum time frame. "Thermin Power Systems Pvt. Ltd." offers Smoke Tube and Water tube Boilers for such applications.

Waste Heat Recovery System

Get Price Quote

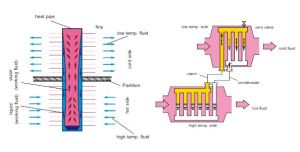

As a high efficiency heat transfer element, heat Pipe has advantages of extremely high thermal conductivity , good isothermality, long-distance heat transfer and temp controllable. HE with heat pipes has excellent performance of high efficiency heat transfer, preventing mix of hot & cold fluids, no dew point corrosion, dust difficultly deposited and no rotating part.

waste heat recovery systems

Get Price Quote

Any exhaust gas stream with temperatures above 150°C has the potential for significant waste heat recovery. Typical examples include plant process heating, combustion air pre-heating, boiler feed water pre-heating and furnace exhaust heat. In addition to savings in everyday fuel consumption, many facilities can market and sell carbon credits back to industry. State funding is often available for waste heat recovery projects helping to reduce capital costs and expedite system payback. Enersys heat recovery systems are designed for ease of installation at industrial facilities. We can generate clean, reliable, and low-cost energy from a wide range of processes. Enersys offers solution to improve the efficiency of these industrial processes while increasing financial returns. VARIOUS SOURCES FOR WASTE HEAT RECOVERY: All boilers, thermal fluid heater systems and related processes Exhaust heat in flue gases from all type of D.G. Sets (HSD fired, LPG fired, and heavy fuel oil fired). Jacket heat recovery from engine. Exhaust heat recovery from gas turbine exhaust. Paper mills Steel plants Oil & gas refineries Textile process Food and pharmaceutical Gas compressor stations Hot waste gases from :– o Scrap steel furnace o Cement kilns o Industrial Furnace o Glass plants o Waste gases from chemical process o Incinerators 1.2 MW saving in Captive Power Plant at m/s Shah Alloys Ltd, Santej, near Ahmedabad.. The heat recovery system generates pressurised high temperature water which is used for process heating, replacing electrical heating of furnace oil and lube oil purification etc. It is integrated seamlessly with the Captive Power Plant (CPP) facility with automatic Control System. The CPP has 7 DG sets (FO fired) to generate more than 6,00,000 units/day. 200 kW Heat recovery facility is supplied to Jindal Steel Ltd, Hissar for saving power from 2500 kW furnace oil fired DG sets. 350 kW Heat recovery facility is supplied to Maral Overseas Ltd, M.P. for saving power from 2 nos 2500 kW furnace oil fired DG sets. A large size “Heat Recovery Air Heater” designed and manufactured for Birla White (Cement), Jodhpur, for kiln exhaust gas. This was in association with Enviro division of Thermax Ltd.

waste heat recovery systems

Get Price Quote

The units are designed to comply with codes such as NR13, Pressure equipment directive (PED), API , ASME , GOST , NORSOK or Australian code. These units are very compact so that the foot print is small. The units are of removable type design often preferred for such applications. These units are designed to heat either thermic fluid, water, water glycol or regeneration gas.

waste heat recovery systems

Get Price Quote

waste heat recovery systems, energy conservation systems

Waste Heat Recovery System

Get Price Quote

Power Plant, steam generating plant

waste heat recovery systems

Get Price Quote

waste heat recovery systems, air pollution control equipments

Waste Heat Recovery System

Get Price Quote

Organic Rankine Cycle, Hydro Turbine Generator, air turbine

waste heat recovery systems

Get Price Quote

waste heat recovery systems, Thermic Fluid Heaters, Hot Water Generators

waste heat recovery systems

Get Price Quote

waste heat recovery systems, Tube & Shell Heat Exchangers