vibratory bowl feeders

Tray Lifting Device

Versatile, Practical Made-to-Measure A tray-lifting device is a versatile, easy-to-use alternative to a crane or manipulator. It is ideal for moving heavy tray stacks quickly and easily from pallets onto conveyor belts, and vice versa. It’s suitable for sortimat Clearliner 400 and 600.

...more

Tray Handler Clearliner

Maximum Speed Minimum Downtime The Clearliner 400 and 600 are ideal for any tray sized up to 400 mm and up to 600 mm. And depending on the quantity of parts and shape of the tray, we can integrate a conveyor belt or trolley for transfer to and from the machine. If a tray stack can be processed rapidly, a conveyor belt is generally the best choice. Stacks can then be removed or replenished while Clearliner is in operation. Both systems are available in a standard version with a single axis, a speed version with two axes, and a special version for cleanrooms up to class 1000 (ISO 6). Sortimat Clearliner 400 Dimensions : 1490 x 1260 x 2350 MM Tray Size : 400 x 600 MM Height of Tray Stack : Max. 900 MM Tray Weight : Up to 30 kg Pick-and-place Time : < 3 sec

...more

Step Feeder

Less Wear and Tear on Parts, Less Noise Guaranteed The sortimat step feeder is used for correctly orienting and transporting small and large parts to a production system. The individual components are separated as they progress up a series of steps, then oriented - at a rate of 60 strokes per minute. The wider the step, the greater the capacity. Because of its size, the step feeder can process large quantities of components without the need for a hopper unit. And a low filling height makes this machine particularly user-friendly. The step feeder is suitable for cleanrooms up to class 1,000/ISO 6. References for the Step Feeder BMW : V8 Engine Assembly Daimler Chrysler : Cylinder Head Assembly Hyundai Motor Group : Engine Assembly Mahle Filtersysteme : Float Housing Robert Bosch : Pump Housing Weber Schraubautomaten : Screws & Nuts(Multiple Track Solution) ZF Lenksysteme : Transmission Assembly

...more

Recharging System

For Large Quantities, CostEfficient & Highly Compatible Sortimat offers a range of solutions for the automatic recharging of sorting and feeding units. Large capacity, and low filling heights ensure process reliability and ease of use. Hopper Systems For the reliable, automated recharging of feeders. A hopper system maintains a consistent volume of components in sorting systems, ensuring they operate reliably and smoothly. Available models: the SMBR with a capacity of 10, 20, and 50 dm³, and the SMBB with a capacity of 30, 60, 80, 100, 150, and 200 dm³. Elevators Elevators are efficient systems for feeding a large variety of different components - from lightweight plastic to heavy steel. Rapid and easy to use, the system’s features include a low filling height and a large capacity.

...more

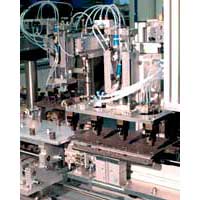

Production Systems

Turnkey Efficiency At sortimat, we take an end-to-end approach to production systems. Not only do we develop and manufacture all our solutions, including feeder units, in-house, we also ensure that they seamlessly integrate with each other. As a result, our assembly and feeder systems support the full range of production tasks, and offer unrivalled efficiency. What's more, we provide open interfaces to incorporate additional systems, such as for packaging and filling – offering extra flexibility. End-to-end production lines comprising multiple sortimat systems are the ideal choice, and guarantee maximum output, efficiency and uptime. For example, you can interlink Jetwings, combine rotary indexing machines with Spaceline systems, and include sortimat feeders. Exceptionally high productivity is the result. Some of the benefits at a glance. Lower costs for project planning, production planning, systems integration and service.Seamlessly integrated turnkey solution – no need to coordinate multiple suppliers.Greater flexibility for product design changes.Standardized components mean fewer assembly steps and easier harmonization of stations.Fewer nests for pre-assembly and final assembly.Increased productivity, reduced downtime, fewer delays between process steps, and less buffering between stations.

...more

High Precision Linear

Linear Rapid State-of-the-Art Spaceline, sortimat’s high-precision linear transfer assembly line, offers outstanding performance for the rapid assembly of complex products in large quantities. Spaceline successfully combines proven innovations with a completely new concept, setting new standards in flexibility, output, speed and cost efficiency. This space-saving assembly line supports 13 to 54 stations, and comprises standard modules that can be combined according to the task at hand, and integrated with additional technologies. The result: future-proof flexibility in the shape of a system that can be expanded, or adapted, to accommodate new products, and new functions. Features Designed for products consisting of a large number of partsCapable of assembling large quantitiesTwin drive that combines a cam drive for stations with a servomotor for advancing palletsIndexed forwards and backwards movement of pallets on the assembly platform. Alternatively, pallets can be returned by means of a conveyor beltSpace-saving design Integration of a Variety of Technologies Cutting, Dosing, Feeder Solutions, hot Sealing, Labeling, Marking, Packaging, Paper Banding, PLC's, Punching and Pressing, Screwing, Testing, Tube Coiling, Vision Systems & Welding Technical Data 13 to 54 stationsUp to 24 tracks and 80 cycles per minuteIndexed feed 100, 200 und 400 mmPallets length 200 or 400 mmPallets width between 140 and 220 mmIndexing time 0.3 seconds (with 200 mm indexed feed)PLCs Siemens S7 or Allen Bradley CLX3710 – 6510 mm total length Highlights Suitable for cleanrooms up to class 10,000 ISO 7. Special versions available for higher-class cleanroomsFlow of parts through machine engineered for clean-room conditionsCombines two pallet cycles, and can operate with a variety of nestsIndividual machine segments can operate with differing cycle times while total output remains at the same high levelQualification according to GAMP 4 is possible, and the technology required for compliance with 21 CFR Part 11 can be provided

...more

Feeders Cleaners

For Reliable Production, Easy Maintenance and Low Downtime The economic, volume-produced sortimat Clearliner is the perfect addition for almost any feeder unit. Modular, cost-effective, standardized, and quick and easy to integrate. The basic module feeds trays to shuttle cars or belt conveyors via a robotic system. Combined with a loading unit, it is an end-to-end solution to your tray-handling needs.

...more

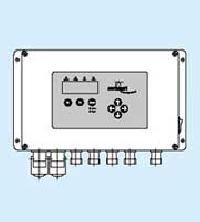

Feeder Control System

Sortimat SMS Electronic Controller Sortimat SMS electronic controllers are designed according to EMC standards EN55011, EN50081-1 and EN50082-2 for the stepless control of vibratory products. Of the three available models, there is one to suit most machines. Direct control by means of a PLC is also possible. Sortimat SMM Multicontroller For feeder units and complex handling systems. The Multicontroller is suitable for end-to-end feeder systems in conjunction with up to three vibratory conveyors and a pick-and-place unit.

...more

Euro ISO Pallets Clearliner

Ideal for EuroISO Pallets & For Your Products Sortimat offers two Handling Systems for EuroISO pallets : The Clearliner 800 (for pallets up to 800 mm) and Clearliner 1000 (for pallets up to 1000 mm). These solutions include loading units that remove trays from pallets, and pick-and-place units that remove components from trays. The handlers are available both with and without a dedicated conveyor. Moreover, they can be optionally constructed for cleanrooms of up to class 10000 (ISO 7). sortimat Clearliner 1000 S1 Tray Processing Time : > 10 sec Conveyor System : EuroISO Pallets Dimensions : 3300 x 2500 x 2700 mm Tray Size : 300 x 400 up to 400 x 600 mm Height of Tray Stack : Max. 1.200 mm Tray Weight : Up to 30 kg Pick-and-place Time : < 3 sec. Scope of Application : Universal. Ideal for machines with short cycle times

...more

drum feeder

Unique Quiet & Compact The drum feeder is an economical, space-saving solution for sorting products using multiple linear tracks. Particularly effective for the transport of small parts that easily become tangled or statically charged, such as springs and o-rings, the drum feeder is often the only way to feed unstable parts in bulk. Drum diameters range from 200 to 800 mm. You can specify a drum length between 60 and 800 mm References for The Drum Feeder Abbott Ireland : Silicon Stoppers Aeropump Germany : Springs For Spray Pumps Baxter Singapore : Y-Pieces for Infusion Sets Becton Dickinson France : Rubber Caps for Cannula Bespak UK : Sealing Rings for Medical Valves NMT UK : Sealing Rings for Safety Syringes Raymond Germany : Silicon Sleeves for Gasoline Pumps Robert Bosch Germany : Fuel Injection Pumps RPC Wiko Germany : Lipstick Brushes

...more

Discovery

Rapid Indexing Precise Versatile Sortimat rotary indexing machines assemble market-ready products in large quantities and accommodate between 12 and 20 stations as standard. Rotary indexing technology is based on a reliable central cam drive for the precise assembly of complex parts. These versatile solutions can also be easily deployed in cleanrooms. Discovery is constructed according to your specific requirements using a standard platform. So you benefit from the combination of outstanding price, outstanding performance and a tailor-made answer to your needs. If you operate in the medical-device or pharmaceutical industries, Discovery can be qualified, and constructed for technical compliance with 21 CFR Part 11. Features For the Assembly of Complex ProductsFor Market-Ready ProductsFor Large QuantitiesDesigned for Easy AccessCentral Cam Drive Integration of a Variety of Additional Technologies Cutting, Dosing, Feeder Solutions, Hot Sealing, Labeling, Marking, Packaging, Paper Banding, PLC's, Punching and Pressing, Screwing, Testing, Tube Coiling, Vision Systems & Welding Technical Data 12, 16 or 20 Stations Available as StandardSpecial Versions Available, Such as two Interlinked Rotary Indexing MachinesUp to 12 Tracks and 150 Cycles Per MinutePLC's Siemens S7 or Allen Bradley CLX Highlights Capable of operation in up to class 10,000 / ISO 7 cleanrooms. Conversion for up to class 100 / ISO 5 is PossibleQualification According to GAMP 4 is Possible, and the Technology Required for Compliance with 21 CFR Part 11 can be Provided

...more

Conveyor System

Fast, Precise & Specialized Linear vibratory conveyors and shaft feeders are classic feeder units that move pre-sorted components along the production line. They are cost-effective, volume-made solutions that ensure high feeding speed and availability. Linear Vibratory Conveyors The linear vibratory conveyor provides a buffer between the feeder unit and the next machine in the process. It is robust, simple in design, guarantees high uptime and little wear and tear even under extreme conditions. Available models: SML 40, SML 80 / 300 �1480. Shaft Feeders The shaft feeder operates exceptionally smoothly, ensuring minimum wear and tear on components. It can be easily integrated into almost any production system thanks to the open design of the output section. The shaft length, shaft rotation speed, and degree of inclination depend on the manufacturing environment and the product itself.

...more

Clearliner

For reliable production, easy maintenance and low downtime. The economic, volume-produced sortimat Clearliner is the perfect addition for almost any feeder unit. Modular, cost-effective, standardized, and quick and easy to integrate. The basic module feeds trays to shuttle cars or belt conveyors via a robotic system. Combined with a loading unit, it is an end-to-end solution to your tray-handling needs.

...more

bowl feeder

Universal Flexible & Reliable sortimat bowl feeders store, convey, sort and orient multiple parts of many shapes and sizeson an incline that spirals around the outside of the bowl. Bolted, interchangeable baffles make this an extremely flexible solution. The cylindrical bowl feeder is available in models SM 100�800, the spiral bowl feeder in models SMB 150-800, and the conical bowl feeder in models SMKF 150-800. Sortimat SMIK Bowl Feeder with Integrated Vision System The rapid SMIK bowl feeder with linear-array camera is the ideal solution when it is not possible to sort parts mechanically, or if a single unit is used to feed a number of diverse components. Incorrectly oriented parts are returned to the sorting process, and unsuitable parts leave the feeder, and good parts are correctly oriented. The system is self-teaching, and can also be set to capture data for quality assurance purposes.

...more

Birkman Feeder

This unique turnkey feeder is supplied ready-assembled and ready-to-go – just plug and play. The Birkman can be configured according to the task at hand, to include a bowl, step or drum feeder, a hopper system, a handling unit for transferring items to downstream systems, and a multicontroller. This is a one-stop solution, and we make sure that all the parts are compatible. So you can save as much as 30 percent of total overhead for engineering, assembly, programming and commissioning. References for the Birkman System in the Automotive Industry BMW : V8 engine assembly Bosch Blaichach : ABS assembly Cooper Power Tools : Cylinder Head Assembly Daimler Chrysler : Berlin Valves Daimler Chrysler Untertürkheim : Cylinder Head Assembly Hyundai Motor Group : Engine Assembly LSW Maschinenfabrik : Feeding of Components for ZF Transmissions VW China : Engine Assembly and Valve Keys VW Kassel : Synchro Rings ZF Saarbrücken : Transmission Assembly ZF Lenksysteme : Schwäbisch Gmünd Axle Assembly

...more

Assembly Cleanrooms Systems

Flexible Solutions for Controlled Environments Manufacturing under cleanroom conditions ensures that products are protected against contamination. This approach plays a vital role in medical technology, the pharmaceuticals and food industries, semi-conductor manufacturing and micro-assembly. Maximum permissible contamination levels vary according to applicable cleanroom class, ranging from 100 (ISO 5) to 100,000 (ISO 8). As a production environment, cleanrooms affect the design of assembly machines. For cleanroom classes 100 to 100,000, these machines must minimize particle count and be very easy to clean. Cleanroom suitability also depends greatly on materials used, utilities, system architecture, air flow and velocity, and temperature. For checktest stations, non-contact technology is generally employed. Almost all sortimat assembly and feeder systems are suitable for cleanroom applications. Features of Sortimat Assembly Systems for Use in Cleanrooms No Actions or Movements Above ProductsFully Enclosed StationsNo Edges, Corners, Recesses or Other AreasParts that are Difficult to AccessIntegrated Air Extraction UnitsEasy-to-Clean DesignProducts do Not Become Statically Charged Integrated add-on technologies are also selected in accordance with cleanroom specifications. For example, preference is given to printing methods with the lowest particle emission rates. For gluing processes, suitable adhesives are used, and air extraction is provided. Features of Sortimat Feeder Systems for Use in Cleanrooms All Parts Made of Stainless Steel or Anti-Static Plastic(Abrasion-Resistant)Large DoorsNo Compressed-Air Technology Used for SortingIntegrated HoodsNo Edges, Corners, Recesses or Other AreasParts that are Difficult to AccessSmooth, Easy-to-Clean SurfacesProducts do not Become Statically Charged

...more

Assembly Machines

assembly automation

medical spms

automatic machines

servo screwing

feeding units

feeding systems

Be first to Rate

Rate This