Weigh Feeder

Design Very Sturdy and Rugged Frame Design Quick Belt change mechanism ensures very low down time. Designed for capacities from 1 to 2000 TPH Unique Dual Load cell design for accurate weighing Feed control inputs from Driving as well as Driven pulleys to ensure Precise feed rate. Accuracy as high as + 0.5% on the set point Electronics Our Electronic controller ensures trouble free interface with the plants processes and control system. Specially developed Software offers seamless integration with PLC or PC ServiceSupport of the customer does not end once the equipment is sold. It is the beginning. With after-sales support being the cornerstone of our business philosophy, we offer prompt and efficient after sales service.

Type : Microprocessor based

Capacity : 1 to 2000 TPH

Accuracy : +/- 0.5% on the set point in control range

...more

VTC-VSP-1 Electronic Screw Packer

Operation of the Machine The Machine to be fitted below the Storage Hopper. Material flows into the damper controlled by Pneumatic Cylinder. The machine will hold bag below which the box or drum has to be put. After completion of filling, the bag will automatically drop in to below box or drum. This machine is a two stage feeding type. On initiating the system both the flap opens & material falls into the weighing hopper. As soon as the 90 % of the weight is reached one flap closes & fine feed starts till the target weight is reached the 2nd flap closes, stopping further fall of material into weighing hopper. The Butterfly Valve provided below the weighing hopper opens & the material falls into the bag through the open mouth bag holder. A Slat Conveyor will be placed below the packing machine which will carry the filled bags.

Condition : Brand New

...more

VTC-PMT-2 Electronic Screw Packer

The Operation Cycles of Auto Filling Machine Vtc-pmt-2 Once the bag is clamped in the Bag holder, machine initiates automatically. The bag holder gets activated by Pneumatic Cylinder. The microprocessor auto-tares the weight & screw feeder rotates at full speed pushing the material into the bag. As soon as the first set point (i.e., approximately 75 to 80 % of target weight) is reached the Microprocessor reduces the speed of the motor through AC Drive & screw feeder pushes the material slowly into the bag. As soon as the second set point reaches (i.e., approximately 95% of target weight) the Microprocessor further reduces the speed of the motor through AC Drive & Screw Feeder pushes the material very slowly into the bag. As soon as the target weight is reached. The screw feeder stops instantly. The filled bag would be released on the slat conveyor. A Stitching Machine/Heat sealing machine will be provided above the conveyor will stitch/Seal the bag. It is also known as Chemical powder packing machine, lime packing machine, pigment packing machine, flour packing machine in open-mouth bags

Power : 3hp

Condition : Brand New

After-Sales Service Provided : Yes

...more

SNCR Denox System

What is SNCR ?Selective Non-Catalytic Reduction is a post-combustion technology that is designed to control nitrogen oxides (NOx) emissions from boilers by the injection of ammonia or urea reagents into the flue gas around 1000 °C. At these temperatures the reaction is fast enough for almost complete consumption of the injected chemical within the available time frame without a catalyst to speed up the process. The purpose of the reducing agent is to enable reduction of the NOx species. The resulting product of the chemical reaction is elemental nitrogen (N2) and water (H2O).Superior Features Long life of components Ease of maintenance Fully automatic in operation. Very little running attention needed Online monitoring and data logging of vital parameters Retrofitting convenience in existing process Better payback period Can be offered with integrated heat recovery system Industry applications Power stations Internal Combustion engines Industrial Boilers Process Heaters Combustion Turbines Incinerators

...more

SCR Denox

What is SCR ? In combustion systems where the flue gases have a short residence time in the temperature window for SNCR reactions, SCR technology will have to be employed. SCR involves injecting either an ammonia or urea reducing agent into the flue gas where a temperature of between 200°C - 550°C exists. The major difference with SCR is that a catalyst is used, which accelerates the chemical reaction and allows it to occur at lower temperatures. SCR technology is capable of achieving >95% NOx reduction

...more

Rice Packing Machine

Voltage : 110V, 220V, 380V, 440V

Condition : New

Automatic Grade : Automatic, Fully Automatic, Semi Automatic

Power : 1-3kw, 3-5kw, 5-7kw, 7-9kw, 9-12kw

Packaging Type : Bags, Bottles, Cans, Cartons, Pouch

Driven Type : Electric, Hydraulic, Mechanical, Pneumatic

Power Source : Diesel, Electric, Gas, Solar

Warrenty : 1year

Weight : 500 gms to 5 Kgs, 5 kgs to 25 Kgs, 10 kgs to 50Kgs

...more

Poha Packing Machine

Application : Making Poha

Weight : 100-500kg, 1000-2000kg, 2000-4000kg, 500-1000kg

Color : Black, Brown, Grey, Light White

Voltage : 110V, 220V, 380V, 440V

Condition : New

Automatic Grade : Automatic, Fully Automatic, Semi Automatic

Power : 1-3kw, 3-5kw, 5-7kw, 7-9kw, 9-12kw

Driven Type : Electric, Hydraulic, Penaumatic

Warrenty : 1year

...more

Jumbo Bag Filling Machine

These models are used for weighing and filling of powder / granules / flakes etc. in jumbo bag (Bulk Quantity). The feeder can be Screw, Flap-Gate of Rotary Feeder. The quantity of filling per bag can be maximum 2000kg. Models are available as Net weigher / Gross weigher type as per requirement. Vibratory compaction system can be provided to vibrant bag during / after filling. It is also known as Powder Packer, Granule Packer, Flakes Packer.

Color : Brown, Creamy, Green, Multicolor, Off White, Red, White

Pattern : Plain, Printed, Striped,Plain and printed

Feature : Durable, Easy To Carry, High Strength, Moisture Resistance, Perfect Finish, Recyclable, Water Proof

Storage Capacity : 100kg, 20kg, 25kg, 30kg, 50kg,1 ton

Feature : Easy To Carry

...more

Hybrid Denox System

Hybrid systems utilizes both SNCR and SCR systems. Typically the SNCR system is utilized to reduce only a portion of the NOx while the NH3 slip is purposely kept high. The remaining NOx is reduced by the downstream SCR catalyst. This catalyst is referred to as a ‘slip breaker’ because it utilizes the unabsorbed NH3 from the SNCR system. Major advantage of the Hybrid system is that the SCR catalyst volume can be significantly reduced (up to 50% reduction) compared with a conventional SCR system.Superior Features Long life of components Ease of maintenance Fully automatic in operation. Very little running attention needed Online monitoring and data logging of vital parameters Retrofitting convenience in existing process Better payback period Can be offered with integrated heat recovery system Industry applications Power stations Internal Combustion engines Industrial Boilers Process Heaters Combustion Turbines Incinerators

Size : 550*350*660 mm

Output Type : 220 AC

Solar power : 10000 Watts

...more

Gravity Flow Packing Machine

Operation of the Machine The Machine to be fitted below the Storage Hopper. Material flows into the damper controlled by Pneumatic Cylinder. The bag will be lifted by bag feeding arrangement from the bag stack. the bag will be reoriented & clamped at the outlet opening of discharge hopper. The bag will be filled to the preset material weight. After filling, the bag will automatically fall down in to the conveyor below which will carry the filled bags. This machine is a 03 stage feeding type for better control and accuracy. The complete system will be operated Electro-pneumatically by using Electronic Controller. Automatic Bag Placer Automatic bag placer is machine which transfers the empty bag from a stack of bags to the hopper where it is clamped and the material is filled. Initially it picks up an empty HDPE/PAPER bag from the stack of bag with the help of vacuum cups. In the next stage the empty bag is transferred to an intermediate stage where it is opened using vacuum cups. Finally, the bag is transferred to the hopper where it is clamped using pneumatic cylinders. The mechanisms are operated pneumatically with logic control interfaced with the other systems. Automatic Bag Dispenser Automatic bag dispenser is machine which transfers the filled bag containing the material from the hopper to the stitching machine using a guided mechanism of linear guides and pneumatic cylinders. After the bag has been completely filled & unclamped the arm extends and clamps the bag from the top & supports it from the bottom/sides & places it onto the conveyor. After the bag has been shifted from the filling machine the dispenser then guides the filled bags directly into the stitching machine. The mechanisms are operated pneumatically with logic control interfaced with the other systems.

Color : Black, Brown, Grey

Voltage : 110V, 220V, 380V, 440V

Condition : New

Function : Packing, Sealing

Automatic Grade : Automatic, Fully Automatic, Semi Automatic

Power : 1-3kw, 3-5kw, 5-7kw, 7-9kw, 9-12kw

Packaging Type : Bags, Bottles, Cans, Cartons, Pouch

Driven Type : Electric, Hydraulic, Mechanical, Pneumatic

Weight : 100-1000kg, 1000-2000kg, 2000-4000kg, 4000-6000kg

...more

Fully Automtic Truck Loading System

Fully Automatic Truck Loading System by V T CORP PVT. LTD. is a compact, efficient, economical and automated system that loads in-layers-arranged bags directly onto trucks. Since its market introduction, customers have already come to appreciate the system’s considerable advantages: high speed, high operational availability and easy maintenance.

Type : Truck Loading Machine

Application : Loading Truck

Color : Green, Orange, Yellow

Condition : New

Automatic Grade : Automatic

Driven Type : Electric

...more

Fully Automatic Truck Loading System

Salient Features Boon for customer who finds difficulty in getting Manpower/ Labor for loading bags in truck Maximize profits by minimizing loading, waiting and delivery times Satisfy your customers with high-quality and stable loads Optimizes loading capacity Increase operator satisfaction Create a safer working environment for personnel Bag Loading MachineThe concept of the three dimensionally adjustable bag loading machine with telescoping head for loading trucks issued to V T CORP PVT. LTD. several years ago.

Weight : 100-500kg, 1000-2000kg, 2000-3000kg, 3000-4000kg, 4000-5000kg, 500-1000kg

Color : Blue, Green, Orange, White, Yellow

Voltage : 110V, 220V, 380V, 440V, 450V

Condition : New

Automatic Grade : Automatic, Fully Automatic, Semi Automatic

Driven Type : Electric, Hydraulic, Mechanical, Pneumatic

Power Supply : 1-3kw, 3-6kw, 6-9kw, 9-12kw

Load Capacity : 1-10ton, 10-50ton, 100-200ton, 200-500ton, 50-100ton

Warranty : 1year

...more

Fully Automatic PFS

OPERATION OF THE MACHINE: The machine is equipped with Robotic Arm which also includes automatic bag placer and dispenser. Which lifts the bag from its stack and applies the bag holder below the discharging spout. A feeder discharges a pre-weighted amount of material in a hopper fitted on a load cell and discharge into the bag. After the bag is filled the Dispenser then Transfers the bag to the Sealing Zone where the bag is stitched and then Discharged. Entire process including the Motorized and Pneumatic System is controlled by Microprocessor Based Controller & PLC. We have different models for higher capacity packing.

...more

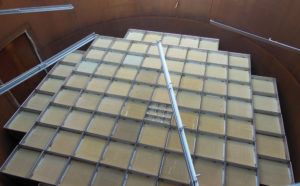

Forced Draft Cooler

What is Forced Draft Cooler?The Forced Draft Cooler is tubular convective type Heat Exchanger used for cooling of hot gases.In Sponge Iron Plants the kiln outlet gases are at approx. 900 to 950 °C. These flue gases cannot be let out to atmosphere as it is and are to be de-dusting. Hence, it is mandatory to provide Dust Collecting system. The major problem of providing the Dust Collecting System is the temperature of the flue gases and it becomes necessary to cool the kiln exhaust gases to around 180 to 220 °C.The best way to accomplish this task is to have air to gas heat exchanger. Although dilution with ambient air / water spray etc. are available for the heat exchanger. Air to gas force draft heat exchanger are the simple, economical & best suited system.Forced Draft Cooler - System DescriptionThe air to gas Cooler is a tubular heat exchanger where, the hot kiln exhaust gases are made to pass over the tubes and cold atmospheric Air is made to pass through the tubes.This system saves considerable energy due to lower pressure drop. Also the cleaning of the FD Cooler is easy as the dusty air is made to pass over the tubes. Since there is practically no moving parts in the system and the design is a modular construction, it is easy to install, and economical and easy to maintain. This system is designed for 24 x 7 operations.Forced Draft Cooler – Advantages No water requirement. Less power consumption due to low pressure drop of the system Low in operating cost – Due to use of ambient air Easier to install, clean and maintenance doe to modular system Less space required – due to modular construction Forced Draft Cooler – Design Basis F D Cooler is for the cooling of flue gases. Flue gas would pass outside the Tubes and cooling air inside the Tubes Easier maintenance of the Heating surface Lesser Choking of the Tubes Low Pressure drop in the flue gas side thereby saving the power consumption I.D. fan Modular construction saves precious time in erection On line cleaning of system with compressed air Blast Over temperature protection Warm cooling air can be used by proper tapping to the advantages of the plant to reduce fuel consumption Individual Force Draft Cooler (FDC) for individual kiln

...more

Tar Electrostatic Precipitator

Application : Textile Industry, PVC Leather, PVC Flooring, PVC Gloves

Electrostatic Precipitator

Application : Textile Industry, PVC Flooring, PVC Leather, PVC Gloves

Electronic Stationary Packer

Vertical Impeller Type Electronic Stationary Packer Micro Processor based stationary and rotary Electronic Packers. Fully automatic Filling & Weighing. Output of the machine is 15 tons/hour/spout. Digital weighing system with indicator Latest technology and user friendly designs Two stages filling of the material inside the bag ensures better accuracy in weighments. Uses pre-stitched valve type bags. Hence, no stitching is required after the bags are filled. Same machine can be used for packing cement in jute, HDPE (woven), or paper bags (non-laminated) Available in 1 to 6 filling spouts in stationary model and 3 to 12 filling spouts in rotary model. Easy availability of spares and after sales service.

Model Number : VTC-VIP-2.3

...more

Electronic Roto Packing Machine

Outstanding Features Micro Processor based stationary and rotary Electronic Packers Fully automatic Filling & Weighing Output of the machine is 15 tons/hour/spout Digital weighing system with indicator Latest stage technology and user friendly designs Two stage filling (coarse & fine) of the material inside the bag ensures better accuracy in weighments Uses pre-stitched valve type bags. Hence, no stitching is required after the bags are filled Same machine can be used for packing cement in jute, HDPE (woven), or paper bags (non-laminated) Available in 1 to 6 filling spouts in stationary model and 4 to 16 filling spouts in rotary model Easy availability of spares and after sales service. Advantages of the Machine Each spout works as an individual unit to fill 50kg cement bags The cement is pushed by the Impeller & since air is required only to fluidize the cement inside the casing, very less air enters into the cement resulting in low spillage The filled bag remains hanging on the Nozzle until the microprocessor ensures actual weight of the bag after the filling cycle is completed & the gate is closed. Bag shall be ejected and discharged on conveyor belt at discharge only. Flow is controlled by a specially designed Slide gate which is operated by 3 position pneumatic cylinder. This Slide gate is available in vertical a swell as horizontal design. It can be use as cement packing machine, Fly Ash packing machine, Gypsum Powder packing machine, bentonite packing machine. Ring aeration provided on the back of the nozzle reduces nozzles clogging

Color : Black, Brown, Grey

Voltage : 110V, 220V, 380V, 440V

Condition : New

Function : Packing, Sealing

Automatic Grade : Automatic, Fully Automatic, Semi Automatic

Power : 1-3kw, 3-5kw, 5-7kw, 7-9kw, 9-12kw

Packaging Type : Bags, Bottles, Cans, Cartons, Pouch

Driven Type : Electric, Hydraulic, Mechanical, Pneumatic

Weight : 100-1000kg, 1000-2000kg, 2000-4000kg, 4000-6000kg

...more

Automatic Weighing Machine

model vtc-vgfp-1.1 is a digital load cell based auto weighing and packing machine controlled by micro-processor based controller. It is suitable for packing granules and powder products like, chemicals, fertilizer, sugar, rice, food grains, pulses, spices, salt, groundnut, sabudana, atta, maida, rava, namkeen, tea, etc. operation of the machine the machine to be fitted below the storage hopper. Material flows with the help of vibratory tray into the damper. on initiating the system flap opens and material falls into the load based weighing hopper. as soon as 90 % of the weight is reached flap closes & fine feed starts filling till the target weight is reached. the gate provided below the weighing hopper opens and the material falls into the bag the continuous sealer provided beside the machine with the help sealer you can pack. salient features of the machine auto filling and weighing electronic microprocessor controlled machine machine can be used for variety of granules materials like spices-granules & powder product. small and compact machine easy to operate and maintain

Type : Automatic Weighing Machine

Weight : 100-200kg, 200-400kg

Color : Red

Voltage : 110V, 220V

Condition : New

...more

Automatic Powder Packing Machine

We are the main supplier of this product.

Type : Automatic Powder Packing Machine

Application : Packing Powder

Color : Light White, Silver

Condition : New

Automatic Grade : Automatic

Weight : 100-1000kg

...moreOpening Hours