Water Heated CO2 Vaporizer

We are specializes in extra ordinary range of Water Heated CO2 Vaporizers which are fabricated, using premium quality raw materials that ensure long life and robust structure. The high performing Water Heated CO2 Vaporizer, offered by us, is widely used in breweries and distilleries. Click Here for More Information

...more

Vertical Carbon Dioxide Storage Tank

We are offering Vertical Carbon Dioxide Storage Tank. Which are fabricated using premium quality materials that offer durable structure and long life to them. The easy to use interface and unique construction design of our Vertical Carbon Dioxide Storage Tank have made them the ultimate option available in the market. Click Here For More Information.

...more

Turbine Flow Meter

Wittemann is engaged in the manufacturing and designing of Turbine Flow Meters, which are renowned for their smooth functioning. Clients’ huge demand has statured us on the top among the listed manufacturers and exporters of Turbine Flow Meter. Features : Complete line of vortex, coriolis and turbine flow metersAccessories for accurate measuringsHigh pressure gasLiquid carbon dioxide streamsCan be supplied with local indicationTantalizationTransmittersAlarm triggers or process controllers Applications : Distilling IndustryBeverage IndustryBrewing IndustryIndustry Gas Industry

...more

Portable Carbon Dioxide Storage Tank

We specialize in extra-ordinary portable carbon dioxide storage tanks that are made as per stringent international quality standards. These portable carbon dioxide storage tanks offered by us can be mounted on mobile vehicles and other different places.

...more

Plc Control Systems

We are one of the leading manufacturers and designers of high quality PLC Control Systems. We manufacture a quality tested range of PLC Based Control System Design that includes PLC based systems and plant automation systems together. These are resistant to vibration and are specially designed for multiple inputs and output arrangements. Our precisely engineered range is energy efficient and is also offered in various specifications to suit specific requirements of clients. Attributes : It reduces the extent of generation equipment needed by tactical systemsImproves equipment utilizationReduces fuel consumption and operating costIt also improve system reliability/availabilityHelps in better management of equipment operation Applications : InstrumentationAutomationBiotechnologyPharmaceutical Industries

...more

Pinpoint Carbonator

Wittemann is the name, which is looked up by clients with the trust for the manufacturing and designing of Pinpoint Carbonators. We are offering a wide range of these Pinpoint Carbonators, which is designed as per the client specifications. Featured with : Injector plates are micro-porousFeatured with large contact surfaces on both sides of the unitBeer passes across the plates as a thin liquid filmLiquid passes between two injector plates as a thin liquid layer which allows for immediate full CO2 saturationStainless steel construction with no hidden crevices, bends or orifices - "Sanitary" designIn-line installation - vertical or horizontalIn-line solution cleaningLowest product pressure drop (less than 0.5psi)Manual or fully-automatic operation is availableStainless steel support stand availableComes with flanged ends as standard or optional tri-clamp connections (tri-clamp connections standard on 1" units)Immediately receiving full CO2 saturation even at the lowest possible flow rateFoam head remains stable over long time periodsThe head does recede, CO2 saturation continues to hold at a high levelImmediate saturation and improved bonding provided by pinpoint carbonation reduce foaming during the transfer of beer from Ruh to storage and greatly reduce the beer's air contentResidual CO2 is used for carbonation from Ruh stage to 2.75 volumes or, depending on flow requirements, up to 3.0 volumes in one pass-through Applications : Brewing IndustryDistilling IndustryBeverage IndustryIndustry Gas Industry

...more

Liquid CO2 Transfer Pump

We are offering liquid co2 transfer pump.wittemann is the prime manufacturer and supplier of liquid co2 transfer pumps, which we are exporting in the global markets. Our liquid co2 transfer pumps are acknowledged for their effectual functioning in many industrial applications. applications : beverage industrybrewing industrydistilling industryindustry gas industry specifications : specifically designed for bulk transfer of carbon dioxidedifferential pressures up to 5.2 barg (75 psig)standard capacities up to 132.5 lpm (42 gpm)capacity depending on differential pressure requirements modelmc 1044mc 2capacity20 gpm (75.7 l/m), 160 lbs/min (72.58 kg/min) @ 0 psi or (0 kg/cm2)50 gpm (189.3 l/m), 400 lbs/min (181.44 kg/min) @ 0 psi or (0 kg/cm2)17 gpm (64.3 l/m), 136 lbs/min (61.69 kg/min) @ 40 psi or (2.81 kg/cm2)42 gpm (159.0 l/m), 336 lbs/min capacity (152.41 kg/min) @ 40 psi or (2.81 kg/cm2)14 gpm (53.0 l/m), 112 lbs/min (50.80 kg/min) @ 75 psi or (5.27 kg/cm2)35 gpm (132.5 l/m), 280 lbs/min (127.0 kg/min) @ 75 psi or (5.27 kg/cm2)rpm18001800pressure300 psig (21.09 kg/cm2)300 psig (21.09 kg/cm2)horsepower1.5 to 2 hp (1.12 to 1.49 kw)3 to 5 hp (2.24 to 3.73 kw)suction port size1.5" (38.1 mm)2.5" (63.5 mm)discharge port size1.5" (38.1 mm)2.5" (63.5 mm) click here for more information

...more

Liquid Co2 Stripping System

We are offering liquid co2 stripping system."wittemann" the technology leader in the brewery and carbonated drinks processing equipment, offers another jewel from its inventory in the form of liquid co2 stripping system. Our world class liquid co2 stripping system is praised by our clients for the following attributes. specialty : economical : as it improves purchase cost of co2 from outside agenciesensures continued & large quantity of co2easy operation with minimal human presencecuts down on cost of monitoring equipmentreduces purge losses compared to conventional liquefaction systemsensure premium quality co2 in accordance with international standardsmore co2 collected per barrel brewed by allowing early collection from fermenters at less than 99.9% co2 which reduces fermenter blow-off prior to turning-in for co2 collectionprovides a high liquid co2 with oxygen content of 5 ppmv or lessoffers beer flavor stability and prolonged shelf lifelow co2 emissions complies to following standards : asmeu-stamp applications : brewing, distilling unitsbeverage processing industriesindustrial gas industries click here for more information

...more

Horizontal Carbon Dioxide Storage Tank

We are one of the eminent horizontal carbon dioxide storage tanks manufacturers and suppliers, based in vadodara, gujarat. We offer advance and high tech horizontal carbon dioxide storage tanks that are widely used in breweries and beverage processing units for storage of co2. Click here for more information

...more

Flue Gas Recovery System

We are offering flue gas recovery system.we are one of the major manufacturers and designers of optimum quality fuel gas recovery systems in the market. Our flue gas co2 recovery system makes use of the chemical absorption method, where the flue gas is first cooled to ambient temperature, and is reacted against an amine-type co2 absorbing solution. The flue gas is then vented to the atmosphere after co2 recovery has been completed. The co2-rich amine solution is then transferred to the regenerator, and heated (by the low pressure steam) to release co2. why our flue gas co2 recovery systems ? our technology consists of the low heat input requirement for the regeneration of fluids, as well as the low consumption of absorbing solution. Our flue gas co2 recovery systems are designed to perform by providing proven purification techniques that minimizes nitrogen and oxygen in the final product and eliminates no, no2 and other harmful impurities. attributes : recovers in excess of 95% of the co2 contained in the flue gasallows users of co2 to become self-sufficient in their requirements or even have surplus co2by recovering the co2 from the flue gas, you are reducing the co2 emissions to atmosphere click here for information

...more

Evp Co2 Vaporizer

We are one of the most celebrated evp co2 vaporizers manufacturers that are fabricated using advanced machines, wear resistant spares and latest technology, which makes them stand our among their competitors. Click here for more information

...more

Electrically Heated CO2 Vaporizer

We are reckoned in the global markets as the prime manufacturer and exporter of Electrically Heated CO2 Vaporizers. Designed with precision, our Electrically Heated CO2 Vaporizers are demanded by clients on large scale. Click Here for More Information

...more

Distillery Systems

We are offering distillery systems.we are one of the prominent manufacturers and designers of high quality distillery co2 recovery systems in the country. Associated quality construction, and single source responsibility are critical virtues not just fortunate alternatives. The complete range of our services covers engineering, construction, installation, commissioning complete with documentation and on-site training of the operating personnel. why us ? technology and process developed by our team at wittemann – usa, the distillery co2 recovery systems based on the feed raw gas from the molasses or grain based distillery produces final product quality of food grade as per isbt standards and as per or better than international beverage / soft drink industries standards. attributes : customized systems to recover co2 from sources with as low as 80% purityyields co2 with a purity as high as 99.998%completely automatic systems for minimal operator intervention and capacity controlsystem design, material selection (liberal use of stainless steel) and manufacturing technique provides for easy and reduced maintenance requirements and costhigh co2 recovery and efficiency yields more co2 productutilized to enhance product quality or may be sold for increased revenues applications : gas purificationbeverage systemsdistilleriesindustrial plants click here for more information

...more

CO2 Purifier

We are offering co2 purifier.wittemann is the reliable manufacturer and exporter of co2 purifiers, which are designed as per the demand of clients. functioning : modular system for ensuring product qualityremovesliquid wateroilsaromaticvolatile oxygenated hydrocarbonsaldehydesh2scosparticulate harmful impurities prior to fillers, carbo-coolers, etc applications : industrial gas industrybrewing industrydistilling industrybeverage industry click here for more information

...more

Carbon Dioxide Production System

We are offering carbon dioxide production system.we are the leading designer, manufacture and supplier of most reliable and efficient flue gas extraction and direct fired co2 production system. To meet the co2 demands of the soft drink industry, wittemann co2 equipment meets or exceeds the latest co2 quality specifications. Wittemann co2 production systems use proven purification techniques to remove impurities found in flue gas as well as those created by solvent degradation. The result is co2 guaranteed to meet product specifications. whu our co2 production systems? our carbon dioxide production system is designed to perform, providing proven purification techniques that minimizes nitrogen and oxygen in the final product and eliminate no, no2 and other harmful impurities. The result is up to 99.99% pure co2 guaranteed to meet the product demands. Robust component selections and an extensive use of stainless steel throughout the solvent system ensure a long and trouble-free life attributes : maximizes availability of solvent steam for stripping dutypromotes complete stripping of co2 from rich mea steam and avoiding additional stripping action in the re boilerimproves co2 absorption and promotes fuel-savings and cost effective co2 productionour two-pass, dry-back design allows operation at near stoichiometric combustion - important to combat the potentially corrosive effectsextensive low pressure purification yields high purity co2 as well as extends the life of downstream mechanical equipmentthe system employs three (3) stainless steel vessels -- two (2) large diameter, bubbler-type kmno4 scrubbers followed by a third vessel that combines a carbon bed support with a special purifying medium. click here for more information

...more

CO2 Gas Purity Tester

We are offering co2 gas purity tester.wittemann specializes in the designing and manufacturing of co2 gas purity testers, which are designed by experts. The improvisation of many efficient features has made our co2 gas purity testers highly beneficial for various industrial applications renowned for : eliminating confusing cockshose connectionsawkward manipulationusual caustic spillagemaking gas testing simplecleaningproviding accuracy applications : industrial gas industrybrewing industrydistilling industrybeverage industry operating instructions : caution: caustic solution is used in the operation of this instrument. This solution may cause severe burns to the operator if not handled with care. Wear goggles and protective clothing while operating this instrument. preparation of caustic solution : a 20% solution of either potassium hydroxide or sodium hydroxide is recommended for air testing*. To make a 20% solution slowly add 100 grams of potassium or sodium hydroxide crystals to 500 cc's of distilled water and store in a sealed jar. The hydroxide solution may also be purchased from any laboratory or chemical supply company. *a weaker solution may be used, but the tests will take longer and fewer tests can be performed. how to operate : attach a hose from the co2gas supply that is to be tested to the nipple of the absorption burette. Use care when attaching the hose so as not to break the calibrated stem of the absorption burette. If using the 1/100th calibrated burette (10102) place your finger on top of the stem and push gently downward onto the support block to prevent the stem from breaking when attaching the hose. Make sure that the gas supply is regulated to below 10 psi before releasing gas into the purity tester.open both cocks (5005) and allow the gas to sweep through the absorption burette and caustic reservoir to completely displace air in the glassware. If preferred, the bulb may be first filled with water and the water displaced with the gas to be tested.after the sample has been taken, close the cock on the absorption burette first and then close the cock on the caustic reservoir.pour the caustic solution into the reservoir to the line indicated on the bulb (approximately 105 cc).open the cock on the caustic reservoir and allow the solution to flow down into the absorption burette. Absorption of the co2 gas now takes place until only air in the sample remains, the small bubble of which may be moved around by tilting the purity tester slightly, thereby insuring complete absorption of the gas.close the cock on the caustic reservoir and turn the instrument 90 degrees so that it rests on its other frame side. In this position, the unabsorbed gas enters the calibrated neck where the volume is directly indicated. The percentage purity of co2 gas is 99% plus 1/10 of 1% for each division as indicated by the level above the bottom graduation (using the standard absorption burette #10101). There are our other types of absorption burettes available which are listed below.after the test is completed, empty the caustic solution from the purity tester. Place the purity tester over a container and open both cocks to allow the caustic to drain out. Rinse out all traces of caustic with warm water and dry the glassware before returning the tester to its case. absorption burettes available part numbergraduated inscale101010.10%99 to 100%101020.01%99 to 100%101031.00%70 to 99%0.20%99 to 100%101041.00%50 to 100%101050.1095 to 100% click here for more information

...more

CO2 Cylinder Filling System

We are offering co2 cylinder filling system.wittemann is a principal manufacturer and supplier of co2 cylinder filling systems, which are designed by the expert engineers. The high efficiency to perform in the industrial applications has made our co2 cylinder filling system. These co2 purifiers are precision-engineered by the experts, which are hugely appreciated by clients in the global markets. features : high-pressure liquid carbon dioxide pumpsup to 68.9 barg (1,000 psig)discharging pressure for filling cylindersfire extinguishers at rates of up to 16 kg/min (35 lb/min)optional automatic shut-off and mechanicalelectronic weigh scales industries, we serve : brewing industrydistilling industrybeverage industryindustrial gas industry click here for more information

...more

Catalytic Oxidizer

We are one of the leading manufacturers and designers of optimum quality Catalytic Oxidizers in the markets. Its working includes reacting with the harmful air pollutants over a specially designed precious metal catalyst where VOC's are converted to CO2, water vapor (H2O), and usable heat. These harmless byproducts are released to atmosphere or are used in energy recovery techniques to further lower the operational costs. Why Our Catalytic Oxidizers ? Our Oxidizers are designed to protect the product against potential hazardous conditions. To ensure your Oxidizer System's safety, an added feature is provided as standard addition in our Oxidizer Systems, is an automatic purging system. This purging system protects the possibility of residual Hydrocarbons or Excess Oxygen being present in the Oxidizer System upon start-up. Attributes : High PerformanceMinimal CostsOperation Costs [Life-Cycle]Side Reaction Purification TechnologyOperation EaseOperation SafetyReliability Applications : Heat exchangersChemical industriesPrinting industriesLamination industriesTape industries

...more

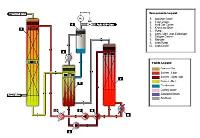

Brewery Recovery System

We are offering brewery recovery system.we are one of the prominent manufacturers of high quality brewery co2 recovery systems in the market. Our recovery plants are the result of many years' of experience and continuous development, based on comprehensive know-how relating to brewing technology and refrigeration engineering. Designed especially for the brew cycle and original gravity we offer our clients custom made brewery co2 recovery systems, which are soon of great benefit for the brewery due to their low investment and operating costs. process : due to extract degradation, alcohol, yeast and also a considerable amount of fermentation carbon dioxide are produced during the fermentation process in a brewery. At the same time, co2 with a very high degree of purity is crucial for production in a modern brewery. With our co2 recovery plants, we offer systems which meet all requirements of efficient carbon dioxide treatment: optimum purity with lowest o2 content and maximum yield. features : recovers co2 from sources with as low as 80% purityprovides co2 with a purity as high as 99.998%automatic systems for negligible operator interventionminimal capacity controlsystem design, material selection and manufacturing technique provides reduced maintenance requirementsmaximum co2 recovery yields more co2 productused to enhance product qualitysold for increased revenues applications : beverage industriesagriculturalbiological sectorcoal beds

...more

Ambient Heated CO2 Vaporizer

We are offering the best Ambient Heated CO2 Vaporizers, which are designed keeping the industrial applications in mind. Embellished with many utility-increasing features, our Ambient Heated CO2 Vaporizers are apt for the efficient functioning. Click Here for More Information

...more

Acid Gas Removal System

We are one of the major manufacturers of high quality Acid Gas Removal Systems in the market. We design and build fuel-efficient plants that use all types of solvents to effectively remove carbon dioxide and hydrogen sulfide from natural gas streams. Our Acid Gas Removal Systems Gas treats the absorption of acid gases such as carbon dioxide and hydrogen sulfide from natural gas, synthesis gas, refinery tail gas, and flue gas. Why our Acid Gas Removal Systems ? Our gas processing facilities are designed to help refiners meet the most stringent environmental regulations and processing requirements. We can build plants that achieve extremely low concentrations, sometimes less than 50 parts per million, of carbon dioxide, often eliminating the need for further treatment in low temperature/cryogenic facilities such as nitrogen rejection and helium recovery plants. Attributes : Corrosion resistantFoaming resistantPrevents chemical losses and degradationHigh quality and performanceNo maintenance and operating costs Applications : InstrumentationAutomationBiotechnologyPharmaceutical IndustriesCoal syngas

...more

Liquid Co2 Stripping System

carbon dioxide gas purity tester

carbon dioxide purifier

Be first to Rate

Rate ThisOpening Hours