Silicone Rubber Moulding Part

Request for Price

1 Box (MOQ)

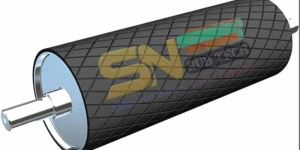

Polyurethane, Natural, EPDM, Neoprene & Silicone Rubber Moulding Parts

Durable rubber moulding parts made from Polyurethane, Natural Rubber, EPDM, Neoprene, and Silicone Rubber, designed for high-performance applications with resistance to wear, weather, chemicals, and high temperatures. Perfect for a variety of industries.

Our Rubber Moulding Parts are expertly crafted from a range of high-quality materials, including Polyurethane, Natural Rubber, EPDM (Ethylene Propylene Diene Monomer), Neoprene, and Silicone Rubber, each chosen for their unique properties and suitability for various industrial applications. These rubber components are designed to provide superior performance, durability, and resistance under challenging conditions.

Polyurethane offers high abrasion and tear resistance, making it ideal for heavy-duty applications.

Natural Rubber is known for its excellent elasticity and resilience, perfect for use in shock-absorbing components.

EPDM provides outstanding weather, ozone, and chemical resistance, making it suitable for outdoor and automotive applications.

Neoprene is versatile, offering good resistance to oils, weathering, and flame, commonly used in seals and gaskets.

Silicone Rubber excels in high-temperature stability and flexibility, making it perfect for medical, food, and high-heat environments.

Our rubber moulding parts are customizable to meet the specific needs of your project, offering a high level of performance, reliability, and cost-efficiency for a wide range of industries, from automotive and aerospace to manufacturing and medical devices.

Country of Origin : India

Type : Moulding Part

Material : Silicone Rubber

Application : Industrial Applications

Shape : Custom Shapes

+1

+1