Welding Positioner

Positioners provide steel fabrication shops with the most up-to-date equipment for placing bulky fabrications in the ‘downhand’ position in the shortest possible time without the use of cranes and manpower. The positioners tables rotate at accurate and constant variable speeds and tilt through 135° with a high C.G. load rating covering almost all anglers for welding any angular job placed on it. Positioners can be supplied for interfacing with Column and Boom Manipulator. FEATURES: Robust all steel fabrication Variable or single speed table rotation through 360° Square or round table as desired. with T slots and concentric rings to facilate fast and accurate alignment and clamping. Power Operated Table tilting mechanism through 135°, including limit Switches to prevent over-run. Centre spindle carried in sealed pre-loaded Timken bearings or, depending on capacity Large diameter crossroll bearing is provided. Accurate machine cut steel gears. Efficient built-in earthling. Totally enclosed electrical motors including electromagnetic breaks. Pendant remote push button controls for all movements, together with speed potentiometer

...more

Welding Hose Pipes

Traversing Rotators

AMIN’s Traversing Rotators (Conventional / Self Aligning) follow the well established reputation of their static counter-parts for ease of use and reliability. We are providing an economical and practical platform for all cylindrical vessel rotating problems. The Traversing Rotator ranges are all bogie mounted to carry vessels of various lengths, and to allow for traversing, in addition to rotation at the work site. Traversing Rotators are built to the highest standards with quality materials and components : - Robust, all-steel construction- Inverter controlled traversing and rotation at welding speeds.- All rollers of the Drive Section positively driven. Whatever your requirement – large or small, short or long – you will find that AMIN has the solution in Stationary or Traversing Rotators.

...more

Self Aligning Rotators

Self Aligning Rotator construction such that the trunnion brackets which support the wheels automatically align themselves when changing from one diameter to another, no manual adjustment whatsoever is required. Each section supports the vessel / Job on four points ensuring better traction, and on machines of 3 T to 500 T capacity and upwards 50 metric tonnes all four wheels of the drive section are positively driven. This four point suspension is an added advantage when on handling thin walled vessels. The two top leading wheels of the drive section incorporate clutches which are loosened prior to loading the vessel and the top wheels can rotate freely when the vessel is loaded; thus regardless of weight if the vessel is lowered centrally between the frames, or firstly on to one wheel only, no damage can be sustained by the transmission.

...more

Rotary Turn Table

Rotary turn tables are used for precise positioning in the flat or horizontal position. High-precision, cost effective method of rotating a workpiece around a vertical axis.

...more

Motorised Material Transfer Wagon / Trolley

Motorized Material Transfer Wagon/Trolley is meant for transferring material from one bay (shop) to another.Wagon/Trolley moves on Indian standard rail section grouted in ground. Material Transfer Wagons / Trolleys are manufactured with load carrying capacities from 5MT to 500 MT capacities as per customer's requirement. Salient Features Of The Transfer Wagon / Trolley Are As Follows: Transfer Wagon/Trolley has two drive wheels and two idler wheels. Power through both drive wheels has separate gear boxes and electric motors. Both motors are synchronized through AC Variable Frequency Drive. Depending upon the load bearing capacity of transfer wagon/trolley, number of drive wheels and idler wheels are provided. Radio Remote Control is provided to move wagon/trolley to and fro. Spring buffers / Disc springs, Two way limit switches are given as safety measures. Under voltage / over voltage protection is provided into control panel. Transfer Wagon / Trolley is equipped with Siren and Bacon Lights. Motorised Cable Reeling Drum is provided for cable feeding.

...more

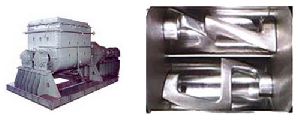

Kneader / Mixer Machine

Kneader/Mixer Machine manufactured by Amin Machinery Pvt. Ltd (AMIN) have two Sigma Blades which are most widely used in Kneader/Mixer machine Design. The Sigma Blades Kneader/Mixer is capable of starting and operation with either liquids or solids or combinations of both. Modifications in blades – face, design have been introduced to increased particular effects, such as shredding or wiping. The Sigma Blades have good mixing action i.e. thorough mixing, readily discharges materials which do not stick to the Sigma Blades, and relatively easy to clean when sticky materials are being processed. The Sigma Blades used in “AMIN” Kneader / Mixer are tangential blades and are run at different speeds, with the advantages of faster mixing from constant change of relative position, greater wiped heat-transfer area per unit volume, and less riding of material above the blades. For “AMIN” Kneader/Mixer machine with Sigma Blades, mixing action is combination of bulk movement, smearing, folding, dividing, and re-combing as the material is pulled and squeezed against Sigma Blades, Saddle and side walls. The Sigma blades are pitched to achieve “End-to-End” circulation. Rotations of Sigma Blades are such that material is drawn down over the Saddle. Clearances are as close as 0.5 Mm. “AMIN” Kneader/Mixer machines are Title d for discharge, to achieve 100 Percent discharge and thorough cleaning between batches. Generally for Kneader / Mixer machines Upto 200 Ltrs. Capacity, the tilting mechanism is manual and over 200 Ltrs. capacity by Hydraulic Cylinders and Power Pack Unit. “AMIN” Kneader/Mixer machines are provided with Water-cooled jacketed trough Body manufactured fromM.S./SS:304/SS:316, For Sigma blades shafts are provided with anti-friction bearing, with properly designed seals and packing glands. Sigma Blades are driven through A.C. Electric Motor, Flexible Coupling/Fluid Coupling /Geared Couplings and open spur gearing mechanism.

...more

Head / Tail Stock Positioner

Headstock and Tailstock positioners generally handle the rotation of long work pieces around a horizontal centreline. The Headstock is generally powered and the Tailstock is free-wheeling with no other support under the work piece. Long complex structures can be turned to make the work execution easier for the welder. In some cases only a Headstock unit is required as shown in the pipespool fabrication arrangement depicted below.

...more

Fit Up Rotators

Our company is engaged in offering manufacturing and supplying a wide range of Wind Mill Tower / Power Rotator, which is available in various speeds, adjustment and diameters as per the clients’ specific requirements. Our range finds usage in Welding, Polishing and Assembling of the cylinder body in diverse industries. The hydraulic fit-up rotators are usually used for fitting up of wind towers / cone pipe assembly welding because of the diameter difference between two sides of the pipe. We have to change the position of the pipe in one end to make the central axes line is in horizontal level, then, the pipe or tank can be rotate smoothly. Hydraulic adjust the center to center spacing of roller group, in accordance with the diameter variations of work piece.

...more

Electrical Control Panels

AMIN MACHINERY, One of the biggest manufacturer of low voltage Electrical & Electronics Control / Power panels / Electrical Enclosure, started its operation 1972. It commands a major market share in its product range category. We are engaged in offereing wide range of Industrial Panels like AMF/DG Panels, Precision-Engineered Panels, MCC Panel, Control Panel, Main Panel, L.T. Panels, Feeder Pillars, Synchronisation Panel, PLC panel and AC Drive Panels and Machine Automation. Major strength of Amin Machinery is modern manufacturing facilities which include sheet metal workshop equipped with shearing Machine, Plate Bending Press Break Machine, Painting technology with bake up oven, tool room quality control systems including Test Benches as per IS And IEC Standards and well equipped design center. In addition to above modern equipment & machinery, we have skilled manpower, highly qualified experienced Engineers, supervisors, Inspector & services technicians for providing prompt & best services after sales requirement, also we have design center, which design the panel to meet the client’s requirement. In addition to above, we manufacture panels strictly adhering to the relevant IS / IEC Standers, electricity rules and other applicable Specifications prevalent and as updated from time to time in this respect. Our Range Of Product Is As Per Follows : Motor Control Center (M.C.C.) / (Power Control Center (P.C.C.) : Bus bar rating upto 3000 Amps. Compact compartmentalized design, extension on either side in future. Selection for top/bottom cable/bus duct entry.

...more

Conventional Rotators

Conventional Rotators are built in capacities from 1T To 2000 Tonnes. The frame is of robust fabricated construction and is machinened on the top and underneath to ensure perfect alignment. Both the drive and the idler frames are provided with robust fabricated and machined wheel brackets which support the axles and bearings of the rollers. According to capacity the Rotators are provided with all Polyurethane wheels with overload disc and all steel wheels. The Rotator base fabrication, or chassis, is designed and fabricated to carry the weight of the vessel / Job and incorporates a contingency for shock loading. It is important that the design eliminates any distortion which can lead to misalignment of the rollers. The drive section comes under the biggest strain when the vessel /Job is being loaded. It is physically impossible for a crane operator to position the vessel so that it contacts with both sets of rollers at the same time. If the work-piece one roller before being supported on all the rollers, the first roller will receive a full shock load which puts a considerable force on to the drive. We have endeavored to incorporate a good overload margin to absorb this shock load.

...more

Column and Boom Manipulator

The Columns of both the RC and TRC types are supported on precision crossroll bearings. The larger machines have pre-loaded cross-roll bearings, which eliminates the free play, and which is extremely important since any play in the cross-roll bearing is considerably increased at the end of the boom when it is in the fully raised and fully extended position. Column rotation can be motorized, but in any case all “AMIN” machines have a manual locking arrangement to lock the column in any of the 360° Positions. The boom saddle, or carriage, is fitted with rollers which travel along the machine slide-ways. Each of the rollers is fitted with pre-loaded Taper Roller bearings carried on eccentric shafts. The Rollers can be adjusted for wear and tear and also for precision and vibration-less travel. Boom elevation is through high torque AC Geared Motor incorporating an electromagnetic brake, the final drive being through rack and pinion. Some of our competitors still employ chain elevation which we consider unsatisfactory since it is impossible to eliminate “bounce”. Bounce accumulates particularly where a Welder’s platform or Lay Trough is fitted and is aggravated by any movement of the welder. Some of our competitors use lead-screw elevation which is unsatisfactory since flux, dust etc. accumulate and the lead-screw then becomes locked in the lead-screw nut. Both chain and lead-screw method are used by this company and discarded some years ago. A further important point is that the actual boom elevation and boom traverse drive is mounted on the saddle itself. “AMIN” ensure that the boom/saddle/welding head, etc. are fully counterbalanced by a weight which moves up and down inside the column, which takes considerable strain away from the elevation gearing. The counter balance weight is connected to the saddle by a heavy duty wire rope/ Leaf Chain which incorporates an anti-fall device. The boom traverse drive is achieved through AC Frequency Variable Drive & AC Motor, reduction gearing and final rack and pinion drive. A most important feature of the “AMIN” machine is the design of the machine slide-ways along-with the very wide rollers, which are carried in the saddle, traverse. Speeds :We understand that the Rotators and Column & Boom Manipulators may be used for cladding operations and we should mention that in these cases very slow movements are essential. We can incorporate in the “AMIN” traverse drive 2 speed gear box which enables the boom to be retracted very slowly, e.g. – The speeds could be 5 mm - 100 mmSecond gear 50 mm - 1000 mm With these speeds it is possible to arrange for the boom to be retracted at very slow speed when spiral cladding, using either the strip method or the wire electrode method. Deflection : We have mentioned above that one way of overcoming this matter is by using a precision cross-roll bearing on which the column rotates. The design of the slide-ways and the very wide service area on which the supporting rollers traverse also helps. However, we have had very considerable experience in Column and Boom design and developed a method of fabrication which enables us to offer Columns and Booms with a much better deflection figure than any of our competitors. We do in fact build in five different designs in order to ensure that the Column and Boom is correct with controlled deflection relative to height, boom travel and weight to be carried. COLUMN & BOOM MANIPULATOR MODELS : Machine Classifications: 1/RMB - 1/TRMB Portable 2/RMB - 2/TRMB Middle weight 3/RMB - 3/TRMB Medium Duty RC - TRC Universal Type Heavy Duty 1/RC - 1/TRC Extra Heavy Duty “AMIN” Column & Boom Manipulators are built in five different designs. These groups cover a range of machines comprising 1/RMB upto Heavy Duty machine 1RC – 12 M x 12 M. The latter machine having 12 Mtr. Maximum height under Boom and 12 Mtr. arc travel. The recommendation as to the most suitable Manipulator to meet requirements depends upon. 1. Length of Boom and maximum height under Boom 2. Weight carried at the end of the Boom – welding head – operator’s seat or lay trough – welder’s platform and additional welder’s walkway running total length of the Boom. Thus, a Column and Boom can have smaller dimensional proportions and yet be of more robust design than a Column and Boom which has a greater horizontal and vertical Boom travel. It will be understood from the classifications that in developing the different groups of machines we have had to take into consideration the very exacting requirements of some of our customers, in particular those engaged in cylindrical vessels manufacture where we have to meet a specification for a Manipulator to carry approximately 300 Kgs. carried at the end of the Boom and maintain a deflection of better than 8 mm. The Manipulator comprises four essential components. FREE STANDING BASE (OR TRAVELLING CARRIAGE)COLUMN – SADDLE – BOOM Much theory has been written on the design of these four main components, but the fact remains that ultimately the machine has to be built and carry out the correct functions required by the customer for his exact requirements. The following points will be of interest. FREE STANDING BASE OR TRAVELLING CARRIAGE : We have developed an extremely robust fabricated design which has a minimum depth to give the necessary rigidity. If the depth of the Base is sacrificed in order to give a slightly lower minimum height under Boom, then some rigidity must be sacrificed. The base top plate is of extremely generous dimension, which varies according to the size of the machine. The Base design is such that the machine is free standing when the Boom is being operated in the maximum height and fully extended. The Base can be either stationary or can be supported on four single flanged wheels to form a Traveling Carriage. Alternatively, two double flanged wheels and two plain wheels to travel along the track-way. In this case the Base incorporate either constant speed or variable speed drive. By utilizing two double flanged and two plain wheels, accurate tracking can be ensured where it is required to weld with the Column traversing. The Column is supported on a cross-roll bearing (not a plain ball bearing, as used by some competitors). The larger machines are fitted with pre-loaded cross-roll bearings, which eliminate the “free-play” at this point, thus reducing Boom deflection. If a ball bearing is used, deflection must arise because all ball bearings must have a clearance. The diameter of the cross roll bearing ranges from 430 mm to 1660 mm Clamps are provided so that when the welding head is in the correct position the Column can be manually securely located. Motorized Column rotation can be incorporated. In this case the cross roll bearing has an integral spur gear on the periphery. In the case of RC/TRC Universal manipulators rotation is achieved an AC motor and one reduction gear box but on the later machines, rotation is achieved through an AC motor and two heavy duty reduction gear boxes, which engage directly with the integral spur gear, thus eliminating backlash. The Column rotation of the large Manipulators with very long Booms incorporates a special drive to smoothen out starting and stopping of rotation, thus reducing the strain, which would otherwise be placed on the reduction drive.

...more

Welding Accessories

Welding Equipment

Welding Rods

Be first to Rate

Rate This