Hot Forging

Get Latest Price

Hot forging has both technical and economical advantages. It provides high precision results along with reduced production times.

Typically a forged metal results in the following :

Drawing Out of the Metal : Increased length decreased cross-section

Upsetting the Metal : Decrease in length decreased cross-section

Change in Length : Change in Cross-Section: resulting in favorable grain flow for strong parts

Tips for selecting the Right Forging Technology :

Technology to remain competitive must come out with cost effective alternatives. That is the reason computer aided techniques like CAD, CAM,CAE and Finite Element analysis (FEA) based computer simulation, are used to selecting the right forging process

Understanding the forged materials’ flow behaviour under processing conditions

Knowledge of the die geometry and materials

Environmental considerations

Evaluating the mechanics of deformation process-stress and strain

Friction and LubriSand Moulding processes

Natured of the Forging Equipment

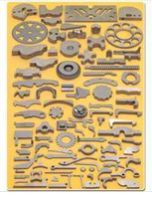

AppliSand Mouldions of Forging Process : Wide Variety of uses in different kinds of industries.Automobile Industry : wheel Spindles, Kingpins, Axle beams and shafts, torsion bars, balls studs, idler arms and steering arm.Agro-Industries : Engine and Transmission components, levers, gears, shafts and spindles to tie-rod ends, spike harrow teeth and cultivator shafts.Aerospace : Bulkheads, hinges, wing roots, engine mounts, brackets, beams, shafts, landing gear cylinders and struts, wheels, brake carriers and discs and arresting hooks, blades, buckets coupling etc.Hand Tools: Sledges, Pliers, Hammers, Wrenches and Garden tools, as well as wire-rope clips, sockets, hooks, turnbuckles and eye bolts are common examples. Industrial Equipment: Connecting rods, blanks, blocks, cylinders, discs, elbows, rings, T’s Shafts and Sleeves.

Methods of Forging :

Impression Die Forgings

Net Shape

Open Die Forgings

Press Forgings

Roll Forgings

Upset Forgings

...more