+4

+4

Wide Throat Pumps

8,000 - 800,000 / Piece

+4

+4

Small Progressive Cavity Pump

5,000 - 100,000 / piece

+2

+2

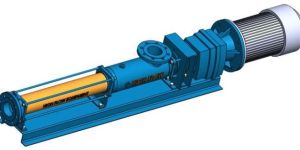

Single Screw Pumps

8,000 - 800,000 / Piece

+3

+3

Single Screw Pump Retrofit Spares

5,000 - 500,000 / piece

+2

+2

Rubber Stator for Screw Pump

5,000 - 500,000 / piece

+2

+2

Progressive Cavity Pumps

3,000 - 500,000 / piece

+3

+3

Progressive Cavity Pump Rotor and Stator

5,000 - 500,000 / piece

+3

+3

Positive Displacement Pumps

8,000 - 800,000 / Piece

+3

+3

PC Pumps

5,000 - 500,000 / piece

+4

+4

Metering and Dosing Screw Pump

5,000 - 500,000 / piece

+5

+5

Helical Rotor Pumps

8,000 - 800,000 / Piece

+2

+2

External Gear Pump

5,000 - 500,000 / piece

+4

+4

Eccentric Screw Pump

8,000 - 800,000 / piece

+3

+3

Eccentric Rotor Pump

5,000 - 100,000 / piece

+4

+4

Compact Mini Progressive Cavity Pump

5,000 - 100,000 / piece

+4

+4

Close Coupled Flange Single Screw Pump

8,000 - 8,000,000 / piece

+4

+4

Chemical Dosing Single Screw Pump

5,000 - 500,000 / piece

+5

+5

Bare Shaft Flange Single Rotor Pump

8,000 - 800,000 / piece

Be first to Rate

Rate ThisOpening Hours