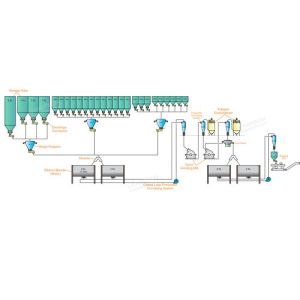

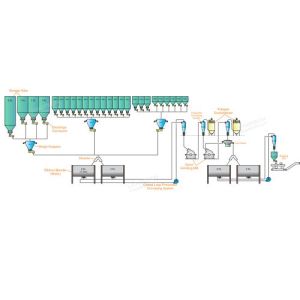

Automatic Batching System

Get Price Quote

Automatic Batching System

Get Price Quote

Auto Batching System

Get Price Quote

Semi Auto Batching System

400,000 / Piece

Automatic Batching System

Get Price Quote

Auto Batching System

Get Price Quote

Auto Batching System

Get Price Quote

Auto Batching System

Get Price Quote

Auto Batching System

Get Price Quote

+2

+2

Preset Batching System

27,000 - 35,000 / piece

Auto Batching System

Get Price Quote

+1

+1

Auto Weighing and Batching System

250,000 - 400,000 / Unit

Auto Batching System

Get Price Quote

Auto Batching System

325 / Bottle

Auto Batching System

Get Price Quote

Automatic Batching System

100,000 - 500,000 / Sets

Auto Batching Proportioning System

Get Price Quote

Auto Batching System

Get Price Quote

Solvent and Chemical Batching System

Get Price Quote

+1

+1

Auto Weighing and Batching System

Get Price Quote

Auto Batching System

Get Price Quote

Auto Batching System

Get Price Quote

Auto Batching System

Get Price Quote

Auto Batching System

175,000 / Piece

Auto Batching System

Get Price Quote

Automatic Batching System

Get Price Quote

Poultry Auto Batching System

Get Price Quote

Auto Batching System

Get Price Quote

Auto Batching Systems

Get Price Quote