Heat treatment Brazing furnaces

Get Price Quote

Wide range of batch and semi-continuous production with process support for different applications such as Hardening and Tempering, Annealing, Sintering, Stress Relieving and Brazing. Standard and custom furnaces are available for a wide range of batch and semi-continuous production with process support for different applications such as Hardening and Tempering, Annealing, Sintering, Stress Relieving and Brazing.

vacuum brazing furnaces

Get Price Quote

Reasons to Braze under Vacuum The following reasons support the use of brazing under vacuum: Calibrated use of alloy with magnesium (4045, 4044, 4104, 4004) to prevent excessive Mg sublimation in the vacuum chamber High final vacuum due to high capacity pumping systems (cryogenic pump + diffusion pumps), which produce a low oxygen atmosphere Rapid transition of the load temperature during the heating phase from 520 °C (starting temperature for Mg sublimation) to 605610 °C thanks to high power furnaces, a feature that prevents an oxidized layer (Al2O3) from reforming on the surface of the piece newly reduced to Al Suitable fixing systems of the individual heat exchanger prevent the piece from collapsing or deforming Uniform load temperature (± 3 °C at 605 °C) is achieved through accurate control of the output power and by distributing the heating zones Cleanliness of the components No emission of contaminated substances into the atmosphere Controlled cooling of the walls and other elements of the furnace with heated water (80 °C) to prevent atmospheric water vapor from condensing during loading and unloading process

Best Deals from Brazing Furnaces

Vacuum Brazing Furnace

Get Price Quote

Details Vacuum Brazing and Annealing Furnace. Vacuum Impregnation System. Plasma Nitriding. Vacuum Carburizing.

Brazing Continuous Furnace

600,000 Per Piece

Brazing Furnace

Get Price Quote

AMI : Offers a versatile selection of Small,Medium & Large Chamber Box Furnaces suitable for a variety of Industrial and Laboratory applications. Advance engineering and specialized Construction techniques include variable density insulation,double shell cabinets,long-life Heating elements and vertical,horizontal side Swing doors.Standard Features : Controlled heat-up rate eliminates thermal shock to material Quick heat up & cool up rate Energy efficient Ceramic Wool & Ceramic Board with fully embedded heating element Unique double-wall construction minimizes external surface temperatures Side-hinge door for convenient operation and full chambers access Long life type "K" type thermocouple Safety door switch to interrupt power to heating element when door is opened protects heating elements Microprocessor based 16 segment PID Controller.

Controlled Atmosphere Brazing Furnace

Get Price Quote

Controlled Atmosphere Brazing FurnacesTPM Depot has a technical tie-up with Shroyoku Sanggyo Furnace Company. We are Specialized in Controlled Atmospheric Brazing furnaces in India , Aluminum Brazing Furnaces,continuous Aluminum Brazing Furnaces Manufacturers in India. These furnaces are being used for brazing aluminum heat exchangers for automotive and other industrial applications.

Stainless Steel Electric Vacuum Brazing Furnace

100,000 Per Piece

brazing furnaces

Get Price Quote

Vacuum Brazing Furnaces are engineered for high temperature laboratories and industrial heat treatment applications that include Sintering, brazing, stress relieving and annealing. Lakshmi Vacuum manufactures a comprehensive range of Vacuum Brazing Furnace that are of top quality and are famous for their durable performance, precision.

Vacuum Brazing Furnace

Get Price Quote

Vacuum Furnaces are suitable for a wide range of Heat Treatment for Tools and Die Steels including Hardening, Tempering, Annealing and Stress Relieving as well as for Vacuum Sintering and Brazing. Heating is done under Vacuum of 5x10-2 millibar and Quenching is done using Nitrogen gas with pressures ranging up to 10 Bar (absolute).

Brazing Furnace

Get Price Quote

We manufacture and supply best quality brazing furnace that is manufactured using latest technology. Brazing furnace offered by us is in compliance with international standards and is duly tested with testing tools and equipment. Our brazing furnace is highly efficient as it is corrosion resistant, requires low maintenance and provides many years of service without any hassles.

Vacuum Brazing Furnace

Get Price Quote

Vacuum Furnaces and brazing furnaces by Bionics Scientific are engineered for high temperature laboratory and industrial heat treatment applications including sintering, brazing, stress-relieving and annealing etc. From aerospace, tool room, powder and metal companies to gas turbine industry, our vacuum furnace units meet most demanding needs of production and research departments. Our vacuum furnaces are horizontal and front loading in nature and manufactured to confirm AMS 2750DBS 5500 Cat 3 British Pressure Vessel standards. The standard units are manufactured with maximum temperature range from 1200°C to 1600°C. Temperature is controlled by 30 segment PID controller, which ensures excellent level of temperature accuracy and reliability. The horizontal vacuum chamber is double walled constructed with provision of water cooling keeping your samples safe from any unwanted conditions.

High vacuum brazing furnace

10,000 - 100,000 Per piece

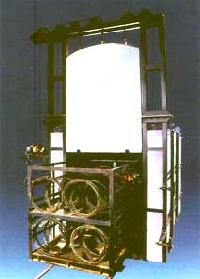

High vacuum brazing furnace for cutting tools and metal parts| Maximum temperature: 1300C. Maximum vacuum: 6x10^(-4) Pa. Work area size: standard/customize (contact us for details). NORMANTHERM Furnace Advantages: Compact design, all the accessories are assembled inside a box-type body frame. PLC intelligent control system, manual/automatic operation, real-time status of LCD touch screen, furnace operation can be intelligent monitored remotely. Vacuum system: a combination of molecular pump and mechanical pump, that eliminates the preheating time, offers fast pumping speed, clean environment, low noise. Also, an integrated water chiller eliminates the need for an external cooling tower. And many more. Furnace application: This equipment is mainly used for high vacuum heat treatment of metal materials, vacuum brazing, etc. Main application industries and processes: diamond tools vacuum brazing, stainless steel vacuum brazing, titanium alloy vacuum brazing, hard alloy, and PCD tool brazing, and other vacuum brazing processes.

brazing furnaces

Get Price Quote

Vacuum heat treatment is a well established practice in the aerospace (OEM and repair), land based turbines, automotive and tool industries. Controlled thermal processing of components is carried out in a vacuum environment to eliminate the deleterious effects of the charge reacting with the gases present in air. The main advantages of this process are bright oxide-free finishes with no carburisation or decarburisation, controlled heating and repeatability without hazardous fumes or toxic waste.

Heat treatment Brazing furnaces

Get Price Quote

Standard and custom furnaces are available for a wide range of batch and semi-continuous production with process support for different applications such as Hardening and Tempering, Annealing, Sintering, Stress Relieving and Brazing. Electrical Resistance Furnace Horizontal & Vertical Design Top, Side and Bottom loading Custom shaped Hot Zones Large Hot zone for Industrial applications Pressure: 10-3 to 10-7 m.bar Temp : from 600 to 2800 deg. C Need based Hot Zone material, Tungsten, Molybdenum, Graphite, etc Charge weight : 200 to 2000 kg Automated heating and cooling cycle, Gas quenching pressure from 3 to 10 bar HHV has global expertise for heat treatment technology and a proven track record on delivery and performance of its equipment. Its customers can rely on a very responsive and dependable technical and service support network in India and abroad.

Vacuum Brazing Furnace

Get Price Quote

Dear Sir, We are interested in a vacuum furnace to manufacture Brazed Diamond Tools. Send us the technical details of your furnace. Some of the details of our requirement are as under. Vacuum Furnace ( Electrically heated) Job to manufacture Vacuum brazed Diamond Tools Hot Zone 20 x 20 x 30 cm (approximate) Loading Horizontal / Vertical Working Temperature 1050 ⁰C Hot vacuum

Brazing Furnace

Get Price Quote

Brazing Furnace, Furnace, Mesh Belt Furnaces

Vacuum Brazing Furnace

Get Price Quote

plasma nitriding furnace, Vacuum Annealing Furnace, Vacuum Furnace

Vacuum Brazing Furnace

Get Price Quote

Aluminium Heat Exchanger, fin press machine, TIG Welding Machine

Brazing Furnace

Get Price Quote

Manufacturer & Exporter of Brazing Furnace & Brazing Furnace Equipments. Our product range also comprises of Ammonia Cracker Furnace, Steam Treatment Furnace and Tempeing Furnace.

copper brazing furnace

Get Price Quote

copper brazing furnace, Mesh Belt Furnace, Carburizing Furnace