Horizontal Machining Center

Get Price Quote

Broadway Foundry & Engg Works manufactures Portable Milling and Boring Machine,Horizontal Machining center and CNC Floor Boring Machine

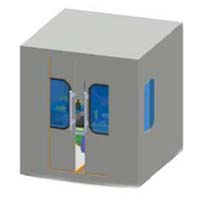

Horizontal Machining Centre

Get Price Quote

We are an eminent Manufacturer and Supplier of Horizontal Machining Centre in Maharashtra, India. We use thick-walled, fine-grain cast iron for the major structural assemblies (base, headstock, and cross slide). The rigid one-piece machine base casting is designed to yield an excellent static and dynamic performance in addition to the outstanding dampening properties that inhibit thermal deformation and twisting. The box type cross slide ensures that the turret remains rigid and stable even during the most rigorous cycles. We also use the extra wide linear guideways that are strategically spaced to provide an excellent support to the cross slide. Our horizontal machining center is optimum for the low to medium-batch or large parts manufacturing production runs. The design promotes better chip control. The gravity does the work with chips falling effortlessly. We design & manufacture a wide range of HMC, as per the client's requirements. We offer HMC's /VMC's of superior capabilities, at affordable prices.

Best Deals from Horizontal Machining Center

CMH Series - Horizontal Machining Center

Get Price Quote

We are offering All three axes movement given to the spindle, LM guide way for all three axes, 1o x 360 number of indexing positions, 404032 mmin rapid rate for XYZ axes respectively, 20 tool ATC, BT-40 spindle Twin arm type tool changing system.

CNC Horizontal Machining Center

Get Price Quote

HORIZONTAL MACHINING CENTER DOOSAN - HP6300

20,000 - 25,000 Per piece

1 Piece (MOQ)

HORIZONTAL MACHINING CENTER MAKE : DOOSAN MODEL : HP6300 CNC: FANUC 18i-MB Number of axis: 4 Spindle taper: ISO 50 Pallet sizes: 630×630 x2 indexed tables Tool magazine: 60 tools Original year: 2007 Fully renovated in 2015

Horizontal Machining Center

Get Price Quote

We are offering Horizontal machining center. Victor brand Made in Taiwan

Horizontal Machining Center

Get Price Quote

Specifications of Kita mura Mycenter H 500 Pallet Size / Number of Pallets 19.7" x 19.7" / 2 Plts Maximum Load on Pallet 1,760 Lbs Contrl Fanuc 15 M X-Axis Travel 31.5" Y-Axis Travel 24" Z-Axis Travel 24" Spindle Taper CAT # 50 Spindle Speeds 35 - 8,000 RPM

Horizontal Machining Center

Get Price Quote

Mild Steel Horizontal Machining Centers

Get Price Quote

1 Piece (MOQ)

MDH Series Horizontal Machining Centre

Get Price Quote

The MDH Series is the ideal machining center for producing box-type and irregular work pieces for automobile, shipbuilding, engine and general engineering industries. The machine is a high-performance, high-reliability and high-precision product characterized by a compact configuration and rapid response rates. The spindle design makes it particularly suitable for heavy power cutting while the excellent ball screw & spindle cooling system provide superb capability for flexible manufacturing. High-speed High-power Spindle The high performance, programmable two speed integrated electric spindle motor means that the MDH is not only capable of high-speed, high-power cutting, but also provides excellent low-speed high-torque cutting. Compact Configuration and Unrivalled Rigidity The machining center is constructed from thick wall box castings providing exceptionally high rigidity. The extra thick castings of the base and column Improve rigidity, and control thermal deformation to a minimum thus keeping exceptionally high precision over extended periods. The unique configuration of the MDH horizontal machining center in which the X-axis moves left and right and Z-axis moves the table forward and backward makes the machine work more effectively. The compact configuration also means that the machine takes up 30% less space than formermachining centers and makes the machine particularly suitable for machining automobile engine cylinder body, large steel components, casting and Aluminum components. High-speed ATC The fully mechanical, cam-operated, ATC system ensure high-speed accurate tool changing with high durability. The cam provides a variable-speed function so that heavy tools are changed smoothly while the single-motor system ensure complete synchronization of the tool clamp/unclamp operation during high-speed ATC operation. Combined with a high-speed automatic shutter, the ATC completes a tool-to-tool change in 2/2.5 seconds, while the cassette-pot magazine design permits flexibility for tool capacity expansion, and boasts a top-class tool weight capacity of 25kg. High-speed APC The direct-drive APC mechanism is designed to lift and rotate only, thus achieving an APC time of only 12.5 seconds as well as accurate table changing operation. A multiple APC system (8 or 10 pallets) can be provided to add flexibility in future system expansion and line configuration. Maximum table loading is 2000 kg.

Super Enamel Horizontal Machine Copper

Get Price Quote

We are capable of handling both automated inbound and outbound consignments, we have excellent warehousing solutions available. We keep the extensive array of products sorted to make sure that the delivery commences thoroughly. Obtain quality-grade Super Enamel Horizontal Machine Copper from us at reasonable prices, as we are reckoned among renowned suppliers of the product.Features : Precise dimensions Sturdy construction Excellent performance Approx Price : Rs 9.5 Lakh / Unit(s)

IMH Series CNC Horizontal Machining Center

Get Price Quote

1 Piece (MOQ)

Features: Reliable ATC System Rotary with 0.001 Degree Fixed Spindle – ZT RAM Type Spindle – ZS HMC combine with high rigidity structure , heavy duty load capacity rotary table and a high torque spindle or high speed spindle along with our professional assembly and hand scrapping skills. HMC can easily overcome most stringent requirements of not only deep hole drilling & boring but high precision mold milling which meet your various needs for today and the future. HMC provide better chips removal ability HMC precision quality and superior performance are designed to meet Aerospace Industry, Transportation Equipment, Energy Industry large parts Machining and Mold Machining Needs.

Dn Solution HP Series Horizontal Machining Centers

Get Price Quote

Unique Features\r\nDesigned to implement highly fast and precise heavy-duty cuttingLM guide on all axes for a higher speed and rigidityHigh torque spindle motor, high feed rate and fast tool exchange time\r\n\r\nDN Solution is one of the largest machine tool companies in the world. With a production capacity of 10,000 machines every year, the company manufactures a wide range of CNC Lathes, Vertical Machining Centers, Horizontal Machining Centers, Horizontal Borers, 5 Axes Machining Centers and Multi-Axis CNC Lathes.

Tool Shank System HORIZONTAL MACHINING CENTER

Get Price Quote

HORIZONTAL MACHINING CENTER - LH 63 BBT50 Tool Shank System. Rigid Monoblock Bed Structure. Coolant through Spindle. Rotar y table with built in Torque motor. High torque Spindle. In-built screw conveyor for chip disposal.

Horizontal Machining Center

Get Price Quote

Pallet Size — 320 x 320 (LH 300) 350 X 350 (LH 350) Pallet Changer — Rotary CNC System — Mitsubishi Fanuc Siemens. Ball Screw Cooling Spindle Oil Cooling System Roller LM Guide ways Efficient Chip management High Rapid Feed Optimize Foot Prints Quick & Easy Access for Maintenance

Horizontal Machining Center

Get Price Quote

Features The major structural parts are manufactured from Meehanite cast iron. X, Y, Z axes are mounted with roller type linear ways, exhibiting extra high rigidity and loading capacity Fixed column construction

Horizontal Machining Center

Get Price Quote

horizontal machining center, ATC (40 tool stations), Flood coolant system, 1 degree x 360 positions table indexing (for PHM 6308001000),AC for CNC cabinet.

Horizontal Machining Centers

3,500,000 Per unit

Horizontal Machining Center

Get Price Quote

Haas Factory Outlet is defined not only by the high-quality Haas products it carries, but also by the outstanding service and applications support it provides. Because we are a factory-direct distributor, we have an extensive inventory of replacement parts available for immediate delivery, and field a fleet of fully stocked service vehicles to provide installation and ongoing service. Our Applications Engineers have the experience to help you select the best Haas product for your application, and provide technical support and training.

DOOSAN HC Series Horizontal Machining Center

Get Price Quote

Doosan is one of the largest machine tool companies in the world. With a production capacity of 10,000 machines every year, the company manufactures a wide range of CNC Lathes, Vertical Machining Centers, Horizontal Machining Centers, Horizontal Borers, 5 Axes Machining Centers and Multi-Axis CNC Lathes.