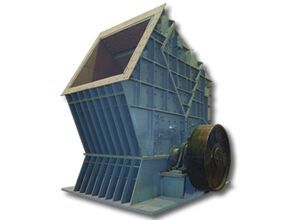

Horizontal Shaft Impactor

Get Price Quote

1 Piece (MOQ)

Horizontal Shaft Impactor

Get Price Quote

1 Piece (MOQ)

Best Deals from Horizontal Shaft Impact Crusher

Horizontal Shaft Impactor

100,000 - 1,000,000 Per Piece

1 Piece (MOQ)

Horizontal Shaft Impactor

500,000 - 3,000,000 Per Nos

Horizontal Shaft Impact Crusher

1,400,000 - 3,500,000 Per Piece

Crushing by impact, as distinguished from crushing by pressure, has its own advantages. Pressure is applied instantaneously during crushing and therefore, breaking by impact almost eliminates the possibility of the development of hidden cracks in the products. This aspect is to noted particularly for road metal. There are generally two types of machines in this category, one Known as an Impact Breaker and the other one as a Hammer Mill. In impact Breaker, the breaker plates are rigidly fixed on the Rotor and swinging type in hammer mill. The impact breaker is a rugged and rigid machine, also provided With a safety device to prevent damage to the rotor etc. In case of Accidental or overload. The impact breaker can crush even hard materials like basalt and granite. Which such rockers the wear on the beaters will be comparatively faster; but as the blades are adjustable, the frequency of replacement is not that high. In addition to its high throughput capacity, the impact breaker Is the machine, which produces the most cubical product. This Is important for road metal, and also for limestone roasting plant because in this case, the product should be uniform and with less fines. An impact Breaker is comparatively a light and simple machine, can be built and supplied in a relatively short time and is therefore preferred for urgent projects requiring high throughput in a short time, as for example, may happen in the case of dam projects. Impact breakers are manufactured in 2 series - 1700 EH for hard material and 1700 EH for comparatively soft material.

Horizontal Shaft Impact Crusher

2,000,000 Per Piece

Horizontal Shaft Impact Crusher

Get Price Quote

Rugged Construction suitable for Primary and Secondary application Best suited for hard materials like basalt and granite Extremely sturdy and all the parts are easily accessible for quick maintenance. High utilization of breaker bars and can be quickly reversed or replaced Rotor fabrication is well balanced to minimize vibration.

Horizontal Shaft Impactor

Get Price Quote

Rullitech Impactors are used as primary and secondary crushers for size reduction of various materials like limestones, Basalt, Blast furnace slag, coal, dolomite, gravel, concrete, asphalt etc., in wet and dry applications. These Crushers offer operators a very high ratio of reduction and can accept larger feed sizes. There are no screens at the discharge opening, thus avoiding plugging. Rullitech Impactors are specially designed to ensure reliability along with easy maintanance, interchangeable wear parts and fast replacement. These crushers require less capital outlay and produce higher percentage of cubical shaped products than competitive type crushers. Operation : Feed enters the primary crushing chamber and meets the blow bars, which impel the feed against the front breaker plate assembly. This action and the collision of material sufficiently reduced in the primary chamber passes by the front breaker plate assembly and enters the secondary chamber for final reduction. Feed Opening : Rullitech Impactors features a very large feed opening. Which enables optimum utilization of the impact chamber, with high capacity rates and excellent size reduction ratios. In, addition, plugging of the material is avoided. Blow Bars : The blow bars are reversible, enabling logner life and less stock keeping. Breaker Plate Assembly: The Breaker plate assembly can be optimally adjusted for particular applications. The breaker plate reaches till below the last crushing element of blow bar. The breaker plates are made of welded steel and are mounted with replaceable blow bars. Rotor : The rotor is mounted on a large diameter forged shaft, which is supported by over-sized, self-aligning, roller bearings located in heavy-duty split bearing housings. The blow bars of the rotor are held in the rotor by a simple locking device. The complete rotor assebly is hard-surfaced in critical areas and thermal stress relieved. Housing : The housing is fabricated with heavy ribs. It is also hinged and has big inspection doors for ease in maintanance. Drive : The Impactor is driven by V-Belts and Electric Motor. Key Features of Horizontal Shaft Impactor: Heavy Duty solid rotor construction. Two, three and four row configurations. Greased oversized bearings. Blow bars available in manganese and various compositions of chrome steels. High Reduction ratios to 30:1. High throughput capacity. Cubical product with high crush count. Selective crushing by speed and breaker plates adjustment. Interchangeable wear parts. Maximum operating reliability. Ease of Maintanance and service.

Horizontal Shaft Impactor

Get Price Quote

1 Piece (MOQ)

HSI Impactor

Get Price Quote

1 Piece (MOQ)

Horizontal Shaft Impactor

Get Price Quote

The Horizontal Shaft Impactor, which we supply, is known for its make and long service life. We stringently make complete arrangements for the vigil examination of the inputs used for the products. By this, we are capable of bringing forth reliable products that are presented after complete inspection and examination by the experts. Our warehouse is well constructed and equipped with all required amenities essential for a safe storage of the products. We also make sure that proper hygienic conditions should be maintained inside the unit.

Horizontal Shaft Impactor

Get Price Quote

SINGH range of Horizontal Shaft Impactors are state of the art Equipment manufactured as per International Standards using high quality raw material. The Crusher is designed to Crush in two or three stages for minimum wear and tear of parts; the incoming feed first strikes the blow bars on the rotor and is then impacted on the primary curtain. When the material is reduced to a stage where it can pass the primary curtain, it is then impacted on the secondary curtains where the final sizing of the finish product is acquired by the setting of gap. Grinding stage can also be fitted so that maximum fines can be achieved in just a single pass. The scientifically designed SINGH horizontal Impactors reduce your Crushing stages due to their high performance, which not only saves your capital cost but has a lowering effect on energy charges. The current and future operating conditions are getting increasingly stringent, and the answer is SINGH Horizontal Shaft Impactor. The best performance from a Horizontal Shaft can be achieved only with the right and optimized Machine layout, a perfectly designed Crushing chamber, specific rotors and liners. The proper combination of SINGH’s large feed opening, high reduction ratio, high capacity, low investment and operating costs can multiply your profitability many fold. Horizontal Shaft Impact Crushers with adjustable curtains are suitable for Crushing medium and hard Stones for the production of asphalt, sand and concrete aggregate. The basic merits of Horizontal Shaft Impactors High tonnage Low capital Investment Cubicle particle shape achieved High specification output achieved Advantages of SINGH Horizontal Shaft Impactors Higher Output High wear resistant parts Heavy Duty Rotor Latest Technology Special arrangement for clamping the blow bars which facilitates maximum return on the blow bar life High Reduction Ratio Robust Construction Flux Core Welded body frame and Rotor Stress relieved body frame and Rotor Forged and Stress relieved EN – 19 Crankshaft Balanced Rotor Wedge locked – Blow bar Ease of Maintenance Hydraulic hood opening System Wedge locking Systems of the breaker bars Closed Circuit lubrication System Replaceable chute liner

HORIZONTAL-SHAFT IMPACT CRUSHER

Get Price Quote

These crushers require a large amount of material filling during impact crushing and have heavy impact plates and robust rotors. As a result, they can process materials in large sizes and have a high crushing capability. In addition, their unique wedge fixing system improves the reliability and simplifies maintenance, while their wear-resisting hard surfaces can ensure a long-time operation in harsh environments. These and other characteristics show that the 1313 series horizontal-shaft impact crushers feature a high output, a low maintenance rate and a long service life, which can bring you a high return on investment.

Horizontal Shaft Impactor (HSI)

Get Price Quote

RD Horizontal Shaft Impact crushers deliver unbeatable performances in primary, secondary, tertiary and recycling applications. It can crush material like Black basalt, limestone, dolomite, Iron ore, Coal.etc. The maximum feed size side of which is between 150-200mm, and the final product is ideal device for aggregation use. RD Horizontal Shaft Impactor has been designed to minimize maintenance and improve all adjustment operations. This impact crusher features reasonable structure, high productivity, easy operation and maintenance and safe performance. The most outstanding advantage of this machine is that its finished material is in cubical shape. Impact Crusher working principle The Impact crush materials with impact force. When the materials enter the blow bar area, they are crushed due to the high-speed impact of the blow bar and are thrown to the impact plates on the rotor for secondary crush. Then the materials will be shot back to the blow bar again for the third crush. This process repeats until the materials are crushed to the required size and discharged from the lower part of the machine. Jaw Crusher Features: Locking sleeve assembly Connection Blow bar with high chrome Hydraulic or hand opening Special impact plate Cubical shape of final product Easy maintenance Reliable performances Simple convenience and low operation cost.

Horizontal Shaft Impactors Machine

Get Price Quote

This is a Heavy Duty Machine. The Material is crushed by impact of Hammers fixed on the outer edge of a spinning rotor. These are used as Secondary Crushers and are designed to crush tougher materials like Basalt, Granite, Quartzite, River Gravel etc.

Horizontal Shaft Impact Crusher

Get Price Quote

HSI (Horizontal Shaft Impact Crusher) is used to produce high quality cubical shape stone aggregate material. They fetch a high ratio of reduction, direct control of product gradation and excellent cubical product shape. Available in three models with capacity 50, 100, 200 tons per hour, High Resistant, alloyed forged steel shaft, fixed to the rotor by means of accurate conical sleeves, assuring the necessary adjustment and easily dismantled. Special bearing housing made of cast steel, with spherical roller bearings, protected against dust by seal labyrinths and bearings lubricated by grease.

HORIZONTAL-SHAFT IMPACT CRUSHER

Get Price Quote

South is celebrated for its high-quality crushers in the industry. South Cedarapids 1313 series horizontal-shaft impact crushers keep South continue to maintain a leading position. These crushers require a large amount of material filling during impact crushing and have heavy impact plates and robust rotors. As a result, they can process materials in large sizes and have a high crushing capability. In addition, their unique wedge fixing system improves the reliability and simplifies maintenance, while their wear-resisting hard surfaces can ensure a long-time operation in harsh environments. These and other characteristics show that the 1313 series horizontal-shaft impact crushers feature a high output, a low maintenance rate and a long service life, which can bring you a high return on investment.

Horizontal Shaft Impactors

675,000 Per Set

1 Set(s) (MOQ)

Horizontal Shaft Impactors series are designed for medium low silica materials. Medium-low silica materials include limestone, dolomite, bauxite, shale, gypsum, coal, Quartz and others. Benefits: To satisfy most applications Wide choice of impact plate and liners Easy replacements of wear and spare parts Many options to increase crusher efficiency One-year warranty Continuing service commitment Global distribution Rapid delivery Superior quality Advanced materials & processes Improved service life of critical components

Horizontal Shaft Impactors

Get Price Quote

1 Piece (MOQ)

We are offering Horizontal Shaft Impactors. These are built with an exclusive combination of standard features that provide value , performance and durability. These crushers with integrated hydraulics are ideally suited to crush hard , abrasive materials down to cubical having a high reduction ratio. capcity range: 50 - 300 tph. models: hs1000 (1000 mm rotor diameter), hs1300 (1300 mm rotor diameter)

Horizontal Shaft Impactor

Get Price Quote

We are prominent manufacturers and suppliers of Horizontal Shaft Impactor which is demanded for its high performance and reliable service. It is designed using latest technology from quality raw material procured from trusted vendors. These Horizontal Shaft Impactor are designed as pet standards laid by the international community. Apart from being durable in nature, these Horizontal Shaft Impactor are anti corrosive, durable and efficient. We offer these Horizontal Shaft Impactor at reasonable prices. We also meet specific demands of our esteemed customers. Benefits of using HSI HSI stands for Horizontal Shaft Impactor. The benefits of using HSI is to get greater production output with comparatively low power requirement HSI crusher has large intakes, which in turns gives an option of using it even in secondary stage crushing Ease of usage gives an added advantage of using an HSI Highest efficiency with low abrasive material Cubical shape output of final production gives added advantage with the application of crushing as well. HSI Crusher Higher capacity with simple structure Easy handling of rotor blade replacement High chromium blade for longer life High-efficiency and energy conservation Easy adjustment of Breaker blades with three stage Breakers Variable output product size to meet custom requirement