Internal CNC Grinders

Get Price Quote

Internal Cylindrical Grinders

Get Price Quote

CNC Production Internal Grinder

Get Price Quote

+5

+5

Diamond Internal Grinding

1 - 1,999 / piece

CNC Internal Grinding

Get Price Quote

+2

+2

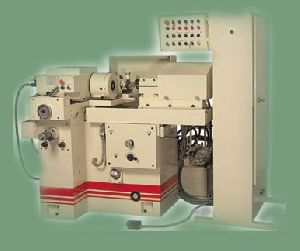

INTERNAL GRINDER OMECA MATIC

3,000 - 10,000 / piece

Internal Grinders

Get Price Quote

Churchill Internal Planetary Grinder

Get Price Quote

Internal Thread Grinder

Get Price Quote

Internal Grinder

Get Price Quote

IG-50 CNC Internal Grinder

Get Price Quote

CLM 2 Internal Grinders

Get Price Quote

Internal Grinders

Get Price Quote

CNC Internal Grinder

Get Price Quote

Internal Cylindrical Grinder

Get Price Quote

Internal Grinder

Get Price Quote

CNC Internal Grinding

Get Price Quote

Internal Grinder

Get Price Quote

Internal Grinder

Get Price Quote

Internal Grinder

Get Price Quote

Precision Internal Grinders

Get Price Quote

Internal Tool Post Grinder

Get Price Quote

Internal Grinding

Get Price Quote

Internal Bore Grinder

Get Price Quote

cylindrical & internal grinding

Get Price Quote