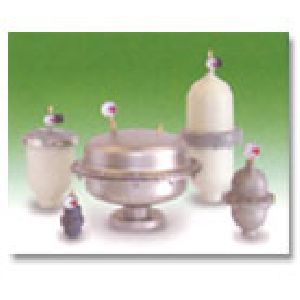

Pulsation Dampener

Get Price Quote

1 Piece (MOQ)

Pulsation Dampener

Get Price Quote

10 Piece (MOQ)

Applications : Energy storage Pulsation Damper/dampener Volume Compensator Pressure Compensator Emergency Energy Reserve Counter Balance Hydraulic line shock Damper Shock Absorbe Hydraulic Spring Fluid Separator Benefits : Minimum Maintenance Very Easy to Operate Energy & Water Saving Standard Accessories Overflow Control Valve Pump Stand Motor-Pump Pulley, Pipe T Piston Ring Set Nozzle Set, Pipe Nipple, Pipe Bend

Best Deals from Pulsation Dampeners

Snubber Pulsation Dampener

Get Price Quote

10 Piece (MOQ)

Pulsation Dampener

Get Price Quote

Available Features : Available in polypropylene & Cast iron.

Pulsation Dampener

4,999 Per Piece

1 Piece (MOQ)

Pulsation Dampener

Get Price Quote

Features : Durability Flawless finish Accurate dimensions

Snubber Pulsation Dampener

Get Price Quote

Features : Designed to reduce dampening effect of process fluid Working pressure up to 400 kg/cm 2 Working temperature up to 120oC All stainless steel construction For corrosive media & environment Application : This device can increase the service life of pressure instruments in critical conditions found at reciprocating Pumps Hydraulic machines Compressors Process plants Clean air,Non crystallized liquids

Pulsation Dampener

Get Price Quote

Most commonly dampeners are used in dosing pump discharge line to eliminate or reduce the pulsating flow nature of reciprocation pump & give continues flow during the operation & results in the smooth & vibration free operation of dosing pump. Design & selection of dampeners are depends on the process parameters of pump like Fluid density, flow rate, Pressure, Suction lift, NPSHA, Pump Acceleration head etc. We dosimix technologies are provide the best suitable dampener solution for the dosing pump.

Pulsation Dampener

22,000 Per Set

1 NOS (MOQ)

We make sure that our inputs are in conformation with the international quality standards and free from all sorts of impurities in order to offer quality-approved products to the buyers. With the assistance of our modern transportation facilities, we are able to deliver the orders on time. Features : Advanced technology Precision engineered Reasonably priced

Gauge Pulsation Dampener

Get Price Quote

Pulsation Dampener

4,500 Per Piece

Pulsation Dampener

10,000 Per Unit

Dampeners

3,000 Per Set

1 Set (MOQ)

Pulsation Dampener

Get Price Quote

Virtually pulsation-free flows Steadier pressures Reduces vibration and noise Available in a variety of sizes and materials Automatically self-charging

Roots Blower Inlet Silencers and Pulsation Dampener

Get Price Quote

The Roots type blower is a positive displacement lobe pump which operates by pumping, or moving, a fluid, usually air, but in some cases a process gas, using a pair of inter-meshing lobed rotors, which have a profile that looks not unlike the number 8. When operating, the fluid is trapped in the outer pockets surrounding the lobes and is carried, or progressed, from one side of the machine to the other. The lobe shaped rotors (usually two lobes, but it can be 3 or 4) work in tandem and move the fluid, usually air, from one side of the machine to the other. The lobes do not grab, or scoop the air out of the inlet pipe, but rather as they pass the inlet opening they cause a local low pressure area inside inlet port of the machine into which the fluid will then flow. As the rotors continue to turn the fluid that has entered the machine is trapped by the rotors and progressed from the inlet side to the outlet side. On reaching the outlet side the fluid has no choice but to be pushed out into the discharge pipe. Each time one of the rotor tips passes either the intake or exhaust port, the passing of that tip causes a pressure pulse to be generated. Therefore in the case of a blower with rotors that have 2 lobes there will be 4 pulses for each complete revolution of the pair of rotors (2 pulses from each rotor for each revolution). This allows for a relatively easy estimation of the principal frequency of pulsation that the machine will generate. Whilst the frequency of the noise from the passing of the rotor tips at the intake and exhaust ports is well understood, there is a second noise mechanism where the fluid tries to pass back through the machine from the high pressure side to the low pressure side by "slipping" around the rotors at their tips. This is an aerodynamic noise mechanism and is less easy to predict as the noise level changes with the speed of the blower and the gap between not only the rotors, but also between the gap between the rotors and the casing. The noise generated by these two mechanisms are quite different. The sound from the passing of the rotor past the open inlet port will have a certain frequency, or tone, which on large low speed machines can literally sound like a large helicopter, whilst on smaller machines which operate at higher speeds this tone may sound like a tuning fork. The aerodynamic sound from the slippage of the fluid back past the rotors is not usually obviously tonal in nature, but rather has a more broadband nature to it, not unlike a valve or pipe exhausting to atmosphere at high velocity.

Pulsation Dampener

Get Price Quote

Pulsation Dampener (Snubbers) are used with pressure gauges where sudden pressure shocks and fluctuations are present which cause the pointer to fluctuate rapidly hence making it difficult to take the gauge reading. Dampers considerably reduce pulsations and hence makes the gauge reading easier and also improves the life of the gauge.

Pulsation Dampeners

Get Price Quote

Piping systems are a central part of numerous engineering installations. A number of sources such as pumps generate vibrations which can propagate along the pipes and excite other structures. These vibrations can cause two main problems, namely mechanical fatigue and acoustical noises. Further, interaction of the dynamic flow generated by the pump plungers with acoustical resonances in piping systems can result in high pressure pulsation levels pump and piping, cavitations, excessive vibrations and failures. Moreover, higher frequency fluid borne noise can be generated from flow perturbations associated with elbows, valves or cross section changes in the pipe. This design approach in conjunction with pulsation simulation is required to couple technical analysis of piping system to ensure that the piping will have adequate supports and clamps to maintain mechanical natural frequency of major acoustical energy.

Pulsation Dampeners

Get Price Quote

Pulsation Dampners are used with pressure gauges where sudden pressure shocks and fluctuations are present which cause the pointer to fluctuate rapidly hence making it difficult to take the gauge reading. Dampners considerably reduce pulsations and hence makes the gauge reading easier and also improves the life of the gauge.

Blacoh

Get Price Quote

Application Glaze Coating P.D. Pumps Discharge Line (Piston, Plunger, Diaphragm, Gear & Peristaltic) Temperature Sensitive Liquids Features & BenefitsUniform SprayingProtects Pipes, Valves, Fittings, Gauges and all Instruments like Pressure Sensors & Temperature Sensors etc.,Protects Piping, Fittings & Instruments during Thermal Expansion.

Pulsation Dampener

Get Price Quote

Technical Details Size range: 3/8-2" Pressure range: 7 bar (maximum) Material of construction (with options): body - polypropylene/kynar/cast iron/stainless steel/aluminum; diaphragm - neoprene/buna N/EPDM/viton/teflon/hytrel/santoprene Applications Used in systems where smooth discharge flow is required Key Features Self priming; can run dry Can have variable flow rates and discharge pressure Can operate at dead head Diaphragm can be submerged in the liquid Are shear sensitive