Tire Recycling Equipment

Get Price Quote

Tire Recycling Equipment

180 - 1,800 Per piece

10 piece (MOQ)

Best Deals from Recycling Equipment

Oil Recycling Equipment

Get Price Quote

SF6 Recycling Equipment

Get Price Quote

Technology Products presents SF6 Evacuating, Refilling & Recycling Equipment. Our evacuating, refilling & evacuating equipment are constructed on a rugged cart with pneumatic tyres which travels easily over hard - surfaced floor or crushed gravel. Permanently mounted to the rugged frame are the vacuum pump, filtering unit, digital vacuum gauges, solenoid vacuum device, safety valves, pressure regulator, hose, and all necessary valves and gauges required for normal servicing of SF6 Circuit Breakers GIS etc.

Wastewater Recycling Equipment

Get Price Quote

1 Piece(s) (MOQ)

We are offering our clients with Waste Water Recycling Equipment known for its high durability and non-corrosive nature and opulent designing. Our trusted and most reliable vendors supply us with premium quality raw materials for best output. Furthermore, these products are manufactured using modern machinery and techniques guided by skilled experts, producing perfect products. Advantages 1. Extremely high scraping speed (2-3 times faster than conventional design) and safety operation. 2. High hydraulic load and low footprint, more effective separation and optimization hydraulic flow in the separation area. 3. Better outlet water quality because of W-shape sludge sedimentation hopper. 4. Effectively minimize chemical consumption because of re-flocculation performance of reverse scraping design. 5. No blind angle in scum collection chamber. Features 1. Design treatment capacity: 100 m3/h 2. High-rate clarifier for medium to low SS water (light particles, oil and colloid) 3. Fully(100%) manufactured in the factory, and no need secondary welding. It costs 3h for 2 manpower to assemble. 4. Indoor or outdoor layout (environmental temperature should be over 0°C). 5. Apply to automatic & continuous operation. Specifications 1)Traditional Flotation with sludge hopper 2)Enhanced separation 3)Compact footprint 4)Lower installation cost 5)W-Hopper

Lead Acid Battery Recycling Equipment

5,000,000 Per Set

"We provide complete range of machinery to set up a Lead Recycling Unit, and more. Our range of machinery can be divided into following categories and includes: Constituent Segregation: • Battery Breaking & Separation Units • Battery Cutting Machines, with or without Terminal Removers, Lock Cutters, Box Crushers, Acid Drainers. Smelting: • Rotary Furnace with Complete Air Pollution Control Systems including Fugitive Emissions Control Systems • Coal Fired Mini Furnaces with Complete Air Pollution Control Systems Refining: • Re-melting Refining Alloying Kettles with or without Fugitive Emissions Control Systems • Ingot Casting Machines Accessories & Other Products: • Effluent Treatment Plants • Jumbo Ingot Moulds • Ball Mills with Collection Systems and Ball Making Machines We provide services for setting up complete Lead Recycling & Smelting Units as per the requirement of clients for specific production capacities in mind. We not only guide the clients in selection of suitable technologies as well as capacity of individual machines equipment, but also the layout of their units and every minute details so that the client does not have to settle for anything but the best."

Waste Oil Recycling Equipment

225,000 - 290,000 Per Piece

1 Piece(s) (MOQ)

Automatic Solvent Recycling Equipments

Get Price Quote

Flexography india press is a global manufacturer & exporter of flexo photo polymer plate making machine, rubber stamp making machine, solvent recovery equipment…etc. For flexographic printing industries…fip group’s head quarter in the viramgam and manufacturing plant in ahmedabad, gujarat,india. Currently, we are manufacturing flexography photopolymer plate making equipment, including rubber stamp making equipment, letterpress plate making equipment, pad printing photo polymer plate making equipment, label photo polymer plate making equipment , varnish photo polymer plate making equipment, flexo solvent recycling unit, liquid resin stamp making equipment, nylon block making equipment , water wash photo polymer plate making equipment , flexo plate making equipment, flexo photo polymer plate making machine all type of stamp making series , embossing plate making equipment, pharmaceutical batch plate making equipment, woven sack photo polymer plate making equipment, flexo photo polymer die making machine , flexo photo polymer block making machine , photo polymer batch coding machine , flexo stereo photo polymer plate making machine , and all type photo polymer plate making machine series .for flexographic printing .

Size Press

4,000,000 Per Set

1 Set(s) (MOQ)

Wastewater Recycling Equipment

Get Price Quote

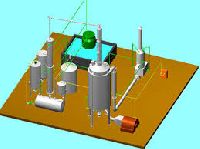

YCRP40 SERIES WET CONCRETE RECYCLING EQUIPMENT

Get Price Quote

SOUTH YCRP40 mobile zero-emission Wet concrete recycling system is the best solution to recycle remaining in concrete mixing station and the remaining concrete from concrete plant and mixer after washed. It can separate sand, soil and grave permanently and utilize the waste water to produce, realizing zero-emission of waste water and waste material. It is a common problem in traditional commercial concrete business that grout is flowing everywhere and waste concrete accumulate. According to statistics, when producing 1 million m3 concrete, the waste amount is equal to 2500m3 concrete and the water wasted made by cleaning equipment reaches 50t. The waste water in the mixing station contains strong caustic materials such as cement hydration product and residual admixture and its PH value is over 13. It will do great damage to surrounding water and soil. It has been standard equipment for a commercial concrete business to have a recycling system. YCRP40 wet concrete recycling equipment developed by SOUTH has 5 characteristics as follows. The customers will feel the high-efficiency and convenience of wet-mixing recovery, with energy-saving and environmental protection.

Waste Oil Recycling Equipment

Get Price Quote

DMAC is an indigenous PETROF technology for refining of used lube oil products. Some of its astute characteristics are: DMAC uses No Hazardous or Banned chemicals. DMAC removes Halogens,heavy metals, Sulfur and oxidized products and bring them withinpermissible limits. DMAC yields high quality base stock with better Color and Oxidation Stability with ZERO CLAY. DMAC Save Complete process Energy Consumption by 30%, as compared to other Processes. DMAC Prevents equipment fouling, corrosion, and coking ofprocess equipment such as heat exchangers and vacuum system. DMAC process separates bottom from feedstock which can be used as asphalt extender, rubber process oil, base for black printing ink, axle grease manufacturing and as rust proofing compound.

Size Press

Get Price Quote

SCAN supplies pond type size press and metering size press. The sizing of the papers can be metered as per the specific requirement. It is also equipped with save all trays for minimizing the wastage of the fluids.

Wastewater Recycling Equipment

1,450,000 Per Unit

Wet Concrete Recycling Plant

Get Price Quote

South YCRP40 mobile zero-emission Wet concrete recycling plant is the best solution to recycle remaining in concrete mixing station and the remaining concrete from concrete plant and mixer after washed. It can separate sand, soil and grave permanently and utilize the waste water to produce, realizing zero-emission of waste water and waste material. It is a common problem in traditional commercial concrete business that grout is flowing everywhere and waste concrete accumulate. According to statistics, when producing 1 million m3 concrete, the waste amount is equal to 2500m3 concrete and the water wasted made by cleaning equipment reaches 50t. The waste water in the mixing station contains strong caustic materials such as cement hydration product and residual admixture and its PH value is over 13. It will do great damage to surrounding water and soil. It has been standard equipment for a commercial concrete business to have a recycling system. YCRP40 wet concrete recycling plant equipment developed by South has 5 characteristics as follows. The customers will feel the high-efficiency and convenience of wet-mixing recovery, with energy-saving and environmental protection.

Vehicle Refrigerant Recycling Equipments

Get Price Quote

Waste Recycling Equipment

Get Price Quote

Advocating energy conservation, pollution emissions reduction, volume reduction and resource recycling, and building a green construction recycling park to accomplish its core concept, South recycles construction wastes and comprehensively disposes resources. The high-quality aggregate recycled by South can be used for concrete, dry mortar, wall materials, and various bricks, blocks and other construction materials. At the same time, plastic pipes, cables, and iron metals are recycled and reused. Wood is processed into renewable wood, while the light-weight fuel materials are reproduced into derivative fuels to turn construction wastes into treasure at a low processing cost, obtain high returns, and achieve the sustainable development in the construction industry, thereby creating great economic values and social benefits. Construction waste recycling and processing equipment developed by South integrates raw materials pre-processing, magnetic separation, sediment detachment and screening, manual sorting, light-weight material separation, and finished product stock bin discharging as a whole. The raw materials mainly refer to construction wastes, and the main finished products are recycled powders, recycled fine aggregates, and recycled coarse aggregates etc.. Using recycled aggregates to produce recycled concrete, mortar, and water stabilization crushed stone can effectively and reasonably reproduce construction wastes into a variety of construction materials. According to the different configurations of the equipment, the construction waste utilization rate can reach 90%-100%, thereby recycling the wastes and obtaining multiple benefits from cost reduction and profits increasing.

Metal Recycling Equipment

Get Price Quote

Today we can hardly imagine life without Steel. Steel, which is an Iron alloy containing carbon, is by far the most used ferrous alloy in our daily appliances. We touch or use ferrous alloys every day and can imagine the enormous application of Iron. From domestic usage (refrigerators, washing machines, microwaves, stoves, burners, furniture, cars etc.) to industrial use (equipments, tools, burners, heavy trucks, computers, nut bolts etc.), today we are totally dependent on these ferrous metals. We understand the minimum resources that we have and hence, “Recycling is Imperative”.

Wastewater Recycling Equipment

12,000 Per Unit

3 Unit (MOQ)

Recycling Equipment

Get Price Quote

We are offering recycling equipment. All kinds of scrap buying best price in chennai