Rotating Disc Contactor

95,000 Per piece

A rotating disc contactor comprising a tubular shell providing a mechanically uninterrupted chamber, one end of which is higher than the other; a rotor shaft which is substantially coaxial with said chamber and is mounted for rotation therein; means for rotating said shaft

Rotating Biological Contactor

Get Price Quote

1 Piece (MOQ)

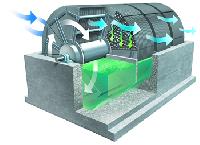

A process cycle ideal for small-to-medium installations comprises, screening (filtergrilles), primary sedimentation with a sludge digestion chamber (Imhoff), biological wastewater treatment with RBC and secondary sludge separation via cloth filter. In compact biocombi installations offered by MITA Biorulli, biological treatment is achieved by means of a partially submerged roller-contactor upon which forms the mass of biological slime: this is created by the growth of micro-organisms which derive their nutrients from the colloids and substances dissolved in the wastewater. MITA Biorulli biocombi series installations do not need final settling tanks; their place is taken by a cloth filter, essentially comprising a horizontal drum in perforated steel sheet covered with a special filter cloth and equipped with an appropriate removal system for the separated sludge. Maintenance is significantly reduced in comparison to traditional plant types and it can be performed by non-specialist personnel. The biological wastewater treatment phase is achieved with a biodisk, comprising parallel polypropylene disks fitted to a central shaft. The diameter varies according to the plant size, from 2,00 m to 2,40 m. The disks have 40% of their surface submerged in the water to be treated and represent an ideal support for the bacterial mass. The cloth filter replaces the secondary settling basin; moreover it ensures a high effluent quality even when both hydraulic and/or suspended solids loadings are variable. The biologically treated water can reach the discharge only via the filter cloth. Its surface acquires a progressively increasing sludge layer which causes an increase in pressure drops. A level sensor activates a pump which, via a suction system placed in contact with the drum, draws, from inside, the water necessary to back-wash the filter cloth. The sludge removed by the water is run back to the primary settling tank, if there is one, or elsewhere. The filter cloth is fabricated using a free-fibre “Polstoff” synthetic material, composed of innumerable overlapped small fibres which provide a very high effluent quality. Key characteristics IDisks are partially submerged (40%) in the liquid to be treated. Deeper Tanks so lower foot print area. Several phases of treatment (biological treatment and sludge separation) are grouped together in a single tank. Process sludge removal with Mecana system cloth filter. Only one gearbox-motor set for movement of the biodisk and filter the filter is firmly connected to the biodisk shaft. Moving parts (disk and fi lter drum rotation) actioned by a motor-gearbox set with output power between 0,75 and 1,5 kW. Supply includes basin in treated and painted carbon-steel with easily removable modular covers in FRP and an electric control panel with IP 55 protection. Discharge concentrations compliant with current wastewater treatment standards. Advantages Minimum energy consumption. Reduced maintenance. Easy access. Reduced installation space requirements (compact construction). Little sensitivity to sudden variations in hydraulic and/or organic loads. High operating safety. Oxygen supply without aeration or diffusion systems. No fl oating sludge problems. Low installation costs. Absence of odour nuisance or aerosols. Pre-assembled plant, ready to be put into service, complete with electric control panel fi tted on the unit which permit rapid installation and start-up. Sectors of application Small communities Tourist complexes and camping sites Construction sites Hotels Schools Motorway service areas

Best Deals from Rotating Biological Contactor

Moving Biological Contactor

1 - 605,000 Per Set

1 Set (MOQ)

Rotating Biological Contactor

400,000 Per Piece

Rotating Biological Contactors or BioDisk Treatment

Get Price Quote

This is a very enhanced technology consuming lot of energy. Here Rotating Biological contactors are medium for biological growth. The contactors are multiple disks attached with each other and submerged partially into water to be treated. The residence time inside gives the reaction time. The rotation lifts the effluent water and microbes on the surface do their job of decomposing them when surface comes out of water level.

Rotating Biological Contactor

Get Price Quote

Rotating biological contactors (RBCs) is a remediation technology used in the secondary treatment of wastewater. This technology involves allowing wastewater to come in contact with a biological medium in order to facilitate the removal of contaminants. There are several different designs now available, but in its simplest form a rotary biological contactor (RBCs) consists of a series of discs mounted on a shaft, which is driven so that the discs rotate at right angles to the flow of settled sewage. These rotating biological contactors offer many advantages like: The capability of handling a wide range of flows. Low power requirements Low sludge requirements Excellent process control. Maintenance and housekeeping requirements are minimal. Only basic operator skills required.

Rotating Biological Contactor

Get Price Quote

RBC is rotated slowly by an electrical motor (geared box) & is arranged in the bioreactor tank in such a way that its half portion is always submerged in the effluent/ sewage. The RBC rotates, the surface of the media is subjected alternately to wastewater/ Sewage and air which encourages an aerobic digestion of organic matter & forms biologically active film of micro-organisms (biomass).(e.g. & picture pending) ADVANTAGES:1. High Efficiency of the plant2. Less space requirement3. Package plant4. Sludge recycling is not required5. Less quantity of sludge generation6. Bio-sludge can be used as manure for garden7. Effectively work for small capacity plant8. Do not require Air Blowers

RBC- Rotating Biological Contactors

Get Price Quote

RBC- Rotating Biological Contactors, MBBR- Moving Bed Bio Reactor

Rotating Biological Contactors

Get Price Quote

Rotating Biological Contactors, Drum Skimmers, Weir Skimmers

Rotating Biological Contactor

Get Price Quote

Rotating biological contactors is a remediation technology used in the secondary treatment of wastewater. Rotating biological contactors are fixed-film reactors. This technology involves allowing wastewater to come in contact with a biological medium in order to facilitate the removal of contaminants.

Rotating Biological Contactor

Get Price Quote

Rotating Biological Contactor, Rotary Water Filters, water filtration skids

Rotating Biological Contactors

Get Price Quote

Rotating Biological Contactors, HAZOP Study Training Services

Rotating Biological Contactors

Get Price Quote

Rotating Biological Contactors

Rotating Biological Contactor

Get Price Quote

Rotating Biological Contactor, Environmental Due Diligence

Rotating Biological Contactor

Get Price Quote

Rotating Biological Contactor

Rotating Biological Contactors

Get Price Quote

Rotating Biological Contactors, Vortex Grit Removal System

Rotating Biological Contactors

Get Price Quote

Rotating Biological Contactors