Tying Machine

Get Price Quote

Automatic Tying Machine

200,000 - 250,000 / Set

+4

+4

Cable Tyeing And Bundling Machine

80,000 - 90,000 / Piece

+5

+5

Cable Bundling & Tying Machine

110,000 / Bag

Portable Twine Tying Machine

325,000 - 325,000 / Piece

Tape Tool Hand Tying Machine

Get Price Quote

Bundle Tying Machine

1,000,000 / Piece

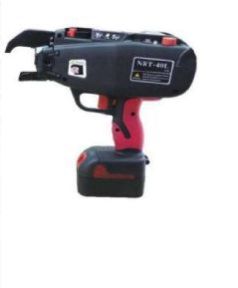

Automatic Rebar Tying Machine

Get Price Quote

Bar Tying Machine

1,200,000 - 4,200,000 / Piece

Rebar Tying Machine

35,000 / Piece

Rebar Tying Machine

Get Price Quote

Cable Twist Tie Tying Machine

Get Price Quote

Tape Tool Hand Tying Machine GT-G236B

Get Price Quote

U TYPE FRAME Warp Tying Knotting Machine

Get Price Quote

Automatic Rebar Tying Machine

Get Price Quote

Rebar Tying Machine

850 / Piece

Wire Winding and Tying Machine

177,000 / Piece

Hand-held Nylon Cable Tying Machine

Get Price Quote

Rebar Tying Machine

Get Price Quote

Warp Tying Beam Knotting Machine

Get Price Quote

Lease to Lease Warp Tying Machine

Get Price Quote

Automatic Rebar Tying Machine

55,000 - 58,000 / Piece

Knotting Frame Tying Machine

230,000 - 240,000 / Piece

Rebar Tying Machine

Get Price Quote

Rebar Tying Machine

Get Price Quote

Rebar Tying Machines

Get Price Quote

Automatic Rebar Tying Machine

42,000 - 42,500 / Piece

Bending and Tying Machine

Get Price Quote

Automatic Rebar Tying Machine

Get Price Quote