AAC Block Manufacturing Plant

800,000 Per Unit

Autoclaved Aerated Concrete Block Plant

12,500,000 - 25,000,000 Per Piece

1 Piece (MOQ)

Best Deals from AAC Block Manufacturing Plant

Harmony AAC Blocks

3,200 Per Cubic Meter

16 Cubic Meter (MOQ)

Advantages High Strength Cost Savings Easy Workability Speedy Construction Energy Efficiency: Better Insulation, Water-barrier and Sound insulation Safe in earthquake prone areas Fire Resistant Thermal Insulation

Autoclaved Aerated Concrete Plants

Get Price Quote

Aac block production plant we are one of professional manufacturers & supplier of autoclaved aerated concrete (aac) plants in india, and we can supply complete set of autoclaved aerated concrete plant with 50000, 100000,150000m3 capacity annually (from 166 m3 to 500m3 per day), including plant design, equipments installation, technical instruction, personal training, etc., and also can design and manufacture as per clients' requirement. plant design: 1. Plant area is 7500-15000 m2, and we can make design based on your actual area of land. 2. Plant should have raw materials field and finished products field; 3. Plant should have maintenance workshop, test room, warehouse,etc. 4. The plant construction time (from earthworks to trial operation) is about 6 month. other features ease of working aac can be drilled, sawed, nailed, and chiseled. Basically, one may work autoclaved aerated concrete like wood, using wood working tools. faster construction aac's advantages in construction is its quick and easy installation since the material can be routed, sanded and cut to size on site using standard carbon tip band saws, hand saws and drills. light weight it weighs approximately 13 of the weight of normal walling materials. Aac provides significant benefits where weight is a concern in building design. Aac is the perfect material for renovations. It causes dead weight reduction of the building and hence the reduction in structural costs. sound proof aac wall has an excellent sound transmission class (stc) rating of 44. Result virtually sound proof interiors. Aac consists 80% air by volume, making it lightest available walling material (weighs 14th that of clay bricks). It was formed as a result of reaction of aluminum on a proportionate blend of lime, cement flyash; the hydrogen gas that escapes creates millions of tiny air cells giving it a strong honeycomb like structure. It is further strengthened by high pressure steam curing in autoclaves. aac block features fire resistant its unique cellular structure provides excellent fire rating. Due to this cellular structure aac blocks do not disintegrate even in fire. It is best in class fire rating of 4 hours. The melting point of aac is over 1600 degree celsius, more than twice the typical temperature in building fire 650 degree celsius. pest resistant with solid wall construction and finishes, there are fewer if any, cavities for insects and rodents to dwell in. Termites and ants do not eat or nest in aac. Being made up of inorganic minerals, it does not promote growth of molds. high strength high pressure steam-curing autoclaving process gives aac unmatchable strength to weight ratio, higher than even m 150 concrete, and far exceeds the indian building code requirements. cost savings being light weight aac drastically reduces the weight of the building. Resulting into reduction in steel (up to 27%) and cement (up to 20%) structural cost savings. Being 8 times the size of a clay brick, aac wall construction involves 13rd of the joints, thus an overall mortar savings up to 66%. Its automatic manufacturing process gives aac an exceptional dimensional accuracy &smooth surfaces, eliminating need of three-coat plaster walls and allows for a final 6mm skin coat (puttypop). thermal insulation highest thermal ratting in the industry. Thus provides well insulated interiors, keeping out warm air in summers and cold air in winters. Aac reduces air conditioning cost by 20%. Aac provides superior thermal insulation due to its cellular structure and results in substantial power savings where air conditioned needs is necessary. go-green nature least carbon footprint with a potential offset of 0.8 tonne co2 per m3. A green building material – contributes to leed rating. earthquake resistant earthquake forces on structure are proportional to the weight of the building, hence aac shows excellent resistant to earthquake forces. Regions of the seismic activities like exclusively use aac. It has been proven to withstand wind loads of category 5 tropical storms. Energy efficient aac is 100% green building material & is a walling material of choice in leed certified buildings (itc centre the highest rated green building has been built using aac) it is most energy and resource efficient in the sense that it uses least amount of energy & material per m3 of product. Unlike brick manufacturing process which use precious layer too-layer agricultural soil, aac uses fly ash (65% to 70% of its weight), thus provides the most constructive solution to the nation’s fly-ash utilization problem. savings in plaster aac blocks have uniform shape and texture, which give even surface to the walls. There is overall 35% reduction in the cost of plastering. Reduction in wastage due to fewer breakages. Unlike conventional clay bricks which are prone to breakages, around 25 %. Aac blocks have almost nil breakages. Reduction in hvac load aac blocks are resistant to thermal variation. They reduce total load of air-conditioning cooling. Though initial installation cost may remain same aac blocks reduces operation and maintenance cost drastically. There is overall 25% saving in operation cost. Floor space area use of thinner blocks (6” instead of 9” exterior walls) because of its excellent water barrier & insulation properties leads to an increase in floor space area between 3-5%.

Aac Block Making Plant

Get Price Quote

1 Piece (MOQ)

Aac Block Plant

2,750,000 Per Set

1 Set(s) (MOQ)

Autoclaved Aerated Concrete Plant

30,000,000 Per Set

Sand Aac Plant

7,500,000 Per Set

1 Set(s) (MOQ)

Aac Blocks Plant

Get Price Quote

We are into the business of manufacturing, exporting and supplying precisely designed AAC Blocks Plant. We have a team of skilled engineers with the help of whom we design and develop our AAC Block Plants using advanced technology. The exceptional performance of our plant is the major reason behind its immense preference. Additionally, we undertake the on-site assembling of the plant.

Aac Plant

Get Price Quote

We are a leading manufacturer and supplier of aac block plant we have been associated to block manufacturing technology since 1990 , from concrete block to flyash bricks , clc and aac , we have seen the change in the market, the product and all the advantages and disadvantages. In aac we have setup multiple turnkey projects, making our team has capable to execute aac block plant projects with ease. Since we have been innovating products for construction industry, our latest vision is to make this technology affordable to the masses. We are also designing smaller size plants which will help to reduce capital investment.

AAC BLOCK MORTAR PLANT

Get Price Quote

Product Introduction Additionally equipped with secondary screw conveying system, finished product storage silo, automatic packing machine based on multi spiral ribbon mixer, to compose an efficient and reasonable simple dry powder mortar mixer with low cost. II. Occupation Area

Aac Plants

Get Price Quote

Autoclaved aerated concrete (AAC), also known as autoclaved cellular concrete (ACC) or autoclaved lightweight concrete (ALC), was invented in the mid-1920s by the Swedish architect and inventor Johan Axel Eriksson It is a lightweight, precast building material that simultaneously provides structure, insulation, fire resistance, Construction Economy and Speed; AAC products include blocks, wall panels, floor and roof panels, and lintelsIt has been refined into a highly thermally insulating concrete-based material used for both internal and external construction. Besides AAC's insulating capability, one of its advantages in construction is its quick and easy installation, the material can be routed, sanded, and cut to size on site using standard carbon steel band saws, hand saws, and drills. Even though regular cement mortar can be used, 98% of the buildings erected with AAC materials use thin bed mortar, which comes to deployment in a thickness of 3 mm. This varies according to national building codes and creates solid and compact building members. AAC material can be coated with a stucco compound or cement plaster OR POP. Materials. Siding materials such as brick or vinyl siding can also be used to cover the outside of AAC materials • AAC has been produced for more than 70 years, and it offers advantages over other cementations construction materials, one of the most important being i ts lower environmental impact. • AAC’s improved thermal efficiency reduces the heating and cooling load in Buildings• AAC’s workability allows accurate cutting, which minimizes the generation of solid waste during use.• AAC’s resource efficiency gives it lower environmental impact in all phases of its life cycle, from processing of raw materials to the disposal of AAC waste.• AAC’s light weight also saves cost & energy in transportation.• AAC’s light weight saves labors. • Reduces the structural weight achieving great economy in RCC work • Low Construction Cost, with high speed output.Main ingredients include fly ash, water, quicklime, cement, aluminum powder and gypsum. The block hardness is being achieved by cement strength, and instant curing mechanism by autoclaving. Gypsum acts as a long term strength gainer. The chemical reaction due to the aluminum paste provides AAC its distinct porous structure, lightness, and insulation properties, completely different compared to other lightweight concrete materials. The finished product is a 2.5 times lighter Block compared to conventional Bricks, while providing the similar strengths. The specific gravity stays around 0.6 to 0.65. This is one single most USP of the AAC blocks, because by using these blocks in structural buildings, the builder saves around 30 to 35 % of structural steel, and concrete, as these blocks reduce the dead load on the building significantly.Assumption The major raw material Fly-Ash, an indispensable by-product of Thermal Power Plants, is an environmental threat across the globe. Power plants are facing an ever increasing challenge disposal of this polluting agent. This unit is proposed to manufacture AAC Bricks & Blocks by consuming the Fly-Ash as one of the prime raw material. Secondly, it also helps environment by saving the invaluable top soil by not using them in brick making like conventional brick making. Thirdly, they need no burning, thus further enhancing their Eco-Friendly Brand. The steam curing requires far less fuel, compared to the backing for each cubic meter of Bricks. This is the reason these bricks are also referred as Eco Bricks or popularly Green Bricks, Carbon Credit estimates are for reference purpose. The Project owner must handle his part of CDM project to get Carbon credits, through independent consultants. Carbon credit can be transacted on registration. The PCN preparation & presentation, the PDD preparation & presentation, host country approval and the UNFCCC Registration might take somewhat 6 months to 2 years year. So it may be wise to start early. Sale price at site is estimated a conservative Rs 3200/- per cubic meter. AAC Blocks of all sizes will be manufactured according to the market requirement, though mainly stipulated sizes as per the BIS standards. Production is estimated at 80% capacity, 300 working days is considered in a year during the first year.

Batching System AAC Plant

Get Price Quote

Aac Plant

Get Price Quote

1 Set(s) (MOQ)

brickvision equipment manufacture and supply best quality aac block plants on very convenient costs. Using the latest technology and hi-tech machinery we provide the best efficiency and time saving systems in our plants. The system is totally electronic based so as to make it cost saving, time saving and efficient as well. model : be-aac-hc-120discreption : this plant is fully automatic machinery : pree mixer, slurry pump, screw conveyor, batching system, micro feeder, plc based control panel, mixer, shifert, track , trolley, cutting machine, boiler, autoclave mad manny more machineryes loaded with full technology. for more details plz meet personaly with your details

Aac Block Production Plant

Get Price Quote

We are one of the professional Manufacturers & Suppliers of Autoclaved Aerated Concrete (AAC) Block Production Plant in India. We can supply complete set of AAC Block Production Plant with 50000, 100000, 150000m3 capacity annually (from 166 m3 to 500m3 per day). The AAC Block Production Plant offered by us includes plant design, equipments installation, technical instruction, personal training, etc., We also design and manufacture the AAC Block Production Plant as per clients' requirement. Plant design : Plant area is 7500-15000 m2, and we can make design based on your actual area of land. Plant should have raw materials field and finished products field. Plant should have maintenance workshop, test room, warehouse, etc. The plant construction time (from earthworks to trial operation) is about 6 months. AAC Block Features : Thermal Insulation : Highest thermal ratting in the industry. Thus provides well insulated interiors, keeping out warm air in summers and cold air in winters. AAC reduces air conditioning cost by 20%. AAC provides superior thermal insulation due to its cellular structure and results in substantial power savings where air conditioned needs is necessary. Go-Green Nature : Least carbon footprint with a potential offset of 0.8 tonne CO2 per m3. A Green Building material contributes to LEED rating. Earthquake Resistant : Earthquake forces on structure are proportional to the weight of the building, hence AAC shows excellent resistant to earthquake forces. Regions of the seismic activities like exclusively use AAC. It has been proven to withstand wind loads of category 5 tropical storms. Energy Efficient : AAC is 100% green building material & is a walling material of choice in LEED certified buildings (ITC centre the highest rated green building has been built using AAC) It is most energy and resource efficient in the sense that it uses least amount of energy & material per m3 of product. Unlike brick manufacturing process which use precious layer too-layer agricultural soil, AAC uses fly ash (65% to 70% of its weight), thus provides the most constructive solution to the nation fly-ash utilization problem. Fire Resistant : Its unique cellular structure provides excellent fire rating. Due to this Cellular structure AAC blocks do not disintegrate even in fire. It is best in class fire rating of 4 hours. The melting point of AAC is over 1600 degree Celsius, more than twice the typical temperature in building fire 650 degree Celsius. Pest Resistant : With solid wall construction and finishes, there are fewer if any, cavities for insects and rodents to dwell in. Termites and ants do not eat or nest in AAC. Being made up of inorganic minerals, it does not promote growth of molds. Other Features : Ease of working : AAC can be drilled, sawed, nailed, and chiseled. Basically, one may work Autoclaved Aerated Concrete like wood, using wood working tools. Faster Construction : AAC's advantages in construction is its quick and easy installation since the material can be routed, sanded and cut to size on site using standard carbon tip band saws, hand saws and drills. Light Weight : It weighs approximately 13 of the weight of normal walling materials. AAC provides significant benefits where weight is a concern in building design. AAC is the perfect material for renovations. It causes dead weight reduction of the building and hence the reduction in structural costs. Sound proof : AAC wall has an excellent Sound transmission Class (STC) rating of 44. Result virtually sound proof interiors. AAC consists 80% air by volume, making it lightest available Walling Material (weighs 14th that of clay bricks). It was formed as a result of reaction of Aluminum on a proportionate blend of Lime, Cement Flyash; the hydrogen gas that escapes creates millions of tiny air cells giving it a strong honeycomb like structure. It is further strengthened by High pressure steam curing in Autoclaves. High Strength : High pressure steam-curing autoclaving process gives AAC unmatchable strength to weight ratio, higher than even M 150 concrete, and far exceeds the Indian building Code Requirements. Cost savings : Being light weight AAC drastically reduces the weight of the building. Resulting into reduction in steel (up to 27%) and cement (up to 20%) structural cost savings. Being 8 times the size of a clay brick, AAC wall construction involves 13rd of the joints, thus an overall mortar savings up to 66%. Its automatic manufacturing process gives AAC an exceptional dimensional accuracy &smooth surfaces, eliminating need of three-coat plaster walls and allows for a final 6mm skin coat (puttypop). Savings in Plaster : AAC blocks have uniform shape and texture, which give even surface to the walls. There is overall 35% reduction in the cost of plastering. Reduction in wastage due to fewer breakages : Unlike conventional clay bricks which are prone to breakages, around 25 %. AAC blocks have almost nil breakages. Reduction in HVAC load : AAC blocks are resistant to thermal variation. They reduce total load of air-conditioning cooling. Though initial installation cost may remain same AAC blocks reduces operation and maintenance cost drastically. There is overall 25% saving in operation cost. Floor Space Area Use of thinner blocks (6 instead of 9 exterior walls) because of its excellent water barrier & insulation properties leads to an increase in floor space area between 3-5%.

AAC Block Manufacturing Plant

60,000,000 - 500,000,000 Per set

1 Set(s) (MOQ)

Aac Plant

900,000 Per Piece

Aac Block Manufacturing Unit

Get Price Quote

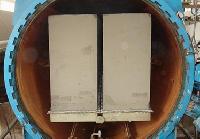

First, the fly-ash (carbon less) is mixed with water, and made as slurry mixture. The slurry is then stored in a storage tank, where it is constantly agitated. Care is taken to ensure that the slurry storage tank is kept running continuously, so that it never settles down the particles. After, a weigh batcher weighs the slurry, lime, OPC Cement (53 Grade), and aluminimum powder (aeration agent) in preset quantities, and mixes thoroughly. The mixture is then poured into a mould cart to fill just around 50% of its area of capacity. The mould is then kept in a warm chamber for 2 hours so that the aeration process and light initial setting takes place. Finally, the mould now becomes a green cake and is ready for the de-moulding process. De-moulding process involves a sophisticated overhead hoist crane which demoulds the cake from its cart and places it onto the cutting line. The cutting line involves the cake being passed through a series of wires for computerized cutting - first horizontally, and then vertically. The final blocks are now steam cured in giant autoclaves for 8 hours at 12KG Sq. cm. pressure and 200 degree Celsius.

Autoclaved Aerated Concrete Plant

Get Price Quote

Autoclaved aerated concrete (AAC), also known as autoclaved cellular concrete (ACC) or autoclaved lightweight concrete (ALC), was invented in the mid-1920s by the Swedish architect and inventor Johan Axel Eriksson It is a lightweight, precast building material that simultaneously provides structure, insulation, fire resistance, Construction Economy and Speed; AAC products include blocks, wall panels, floor and roof panels, and lintels, AAC has been produced for more than 70 years, and it offers advantages over other cementations construction materials, one of the most important being i ts lower environmental impact.

AAC Block Manufacturing Plant

Get Price Quote

Aac Block Manufacturing Unit

Get Price Quote

NXTBLOC, Aerated autoclaved concrete(AAC blocks are a high quality building material that offers a unique combination of strength, low weight, thermal insulation, sound absorption, unsurpassed fire resistance and unprecedented build ability. AAC is a steam-cured mix of sand or pulverized fuel ash(PFA), cement, lime and aeration agent.

Autoclaved Aerated Concrete Plant

Get Price Quote

AAC blocks are one third lighter than conventional clay bricks, thereby reducing the dead weight of the structure drastically,Light weight structure decreases construction cost due to reducing steel, Cement and Excavation.Our Case Study Shows Following Results Reduction in steel = 15 % Reduction in cement = 10%.Due to reduction in dead weight, Reduction in consumption of steel and cement and lesser excavation for foundations, construction time is reduced which in turn results in savings in labor cost and overheads.

Aac Plant

Get Price Quote

Autoclaved Aerated Concrete (AAC) is a fully integrated building system of panels and blocks that are used for residential, commercial and industrial buildings. AAC, a light-weight green building material, is fire resistant and has good thermal insulation, solid structure and is easy to work with. AAC is manufactured by about 200 plants in 35 countries and is used extensively in residential, commercial and industrial buildings.Biltech Building Elements Limited, an Avantha Group Company is engaged in mechanised manufacture of this revolutionary building material in India. Currently BBEL has over 40% of the market share with a capacity of 13, 40, 000 cu.m. per annum. Factory manufactured BILTECH products, make constructive use of pollutant Fly Ash, copiously spewed by Thermal Power Stations. With its manufacturing facilities in north, east and western India, and some more plants coming up in other parts of the country to facilitate pan-India presence and reach, BILTECH commands the status of the largest Fly Ash based AAC manufacturer in India.

Aac Plant

Get Price Quote

1 Piece(s) (MOQ)

We offer aac plant. We are pleased to introduce ourselves as machinery manufacturers and technology providers from new delhi, india for aac plants and other building material projects, fly ashsand lime bricks etc. Our conceptprinciple of business is to provide technology and machinery equal or better than european at economical prices. neither we represent any chinese company nor we use any chinese parts for manufacturing of machinery. we take up aac and other building material projects from concept to commissioning which includes detailed engineering (civil, mechanical, electrical, automation and utilities), machinery selection and manufacturing, erection of total machinery and commissioning we have studied all types of aac plants supplied by chineseeuropean manufacturers and have incorporated several improvements and innovations based on our experience of operating cementfly ash solid bricksblockshollow blockspavers plants with modern automation systems. We are using superior quality components in all the key machinery manufacturing apart from maintaining quality manufacturing techniquesspecifications apart from maintaining highest standards in design engineering of all the machinery from a bolt to critical machines. We request you to visit us to understand our capabilities and quality of machinery being manufactured by us. On your inspection, we are sure you will agree that our concepts and the quality standards being maintained by us are comparable to european and not with chinese. Input costs are approximately as under: density of blocks: 600 kgm3 fly ash: 70-75% = 420-450 kgm3 lime: 7-8% = 48-60 kgm3 (to be obtained from rajasthan) cement: 15-18% = 90-108 kgm3 gypsum 1-2% = 6-12 kgm3 aluminum powder = 0.4-0.5 kgm3 aac(cost about rs. 200 per kg) power 12 kwhm3 boiler fuel: 40 kg coalm3 or equivalent alternate fuel like firewood or rice husk

Aac Block Plant

Get Price Quote

Fostered with enormous business understanding of this realm, we are involved in presenting a broad consignment of AAC Block Plant. Features: Optimum quality Impeccable finish Long lasting nature Industry proven designs

Aac Block Plant Machienry

35,000,000 Per Set

1 Set(s) (MOQ)

Autoclaved aerated concrete plant. We are specialized supplier of complete set of autoclaved aerated concrete plant with 50000, 100000, 150000, 200000, 250000, 300000, 350000m3 capacity annually (from 200 m3 to 1000 m3 per day), including plant design, equipments installation, technical instruction, personal training, etc., and also we design and manufacture as per clients' requirement. Autoclave aerated concrete production line included: raw material: cement, lime, sand, gypsum, aluminum powder, water.

Aac Plant

Get Price Quote

Fully Automatic Fly Ash Brick Making Machines AAC Block Making Plants ( Autoclave Aerated Concrete ) Automatic Fly Ash Brick Machines Semi Automatic Fly Ash Brick Machines Interlocking Paver Block Machines CLC Block Making Machines ( Cellular Light Weight Concrete ) Laying Machines Paver Block Table Vibrators

Aac Plant and Machinery

Get Price Quote

We provide complete solutions for aac plants from consulting to design, manufacture, commissioning and service. We specialize in small to mid-size plants that can be later expanded for large scale production making it easier for our customers to enter the aac space with adequate capital and create a name for themselves before launching a full scale outfit. Combine this with our service quality for excellent results throughout and we present a profitable proposition. For more information, please visit our website.

Autoclaved Aerated Concrete Plant

Get Price Quote

European plant available in India (Non-autoclaved technology) It is also known as light weight brick machinery & light weight bricks making machine. he aerated concrete blocks. The mixer for aerated concrete is placed fixedly, the moulds transfer from pouring point to cutting point. Loading and dosing of components are carried out automatically - the materials through belt and screw conveyors are fed to intermediate hoppers suspended on the tensiometers. Dosing control terminal in case of reaching required weight turns off the conveyors. Components are poured into the mixer manually by opening of the bolt. Cutting of an array is carried out with the automatic cutting installation. Movement of the moulds on the rail track is organized through automatic push devices.

Autoclaved Aerated Concrete Plant

Get Price Quote

We are offering european non autoclaved aerated concrete plant (naac). This set of equipment is designed to produce the aerated concrete blocks. The mixer for aerated concrete is placed fixedly, the moulds transfer from pouring point to cutting point. Loading and dosing of components are carried out automatically - the materials through belt and screw conveyors are fed to intermediate hoppers suspended on the tensiometers. Dosing control terminal in case of reaching required weight turns off the conveyors. Components are poured into the mixer manually by opening of the bolt. Cutting of an array is carried out with the automatic cutting installation. Movement of the moulds on the rail track is organized through automatic push devices.