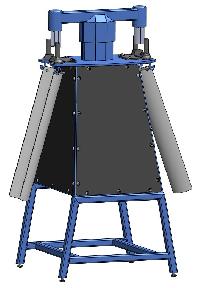

Vertical Shaft Impact Crusher

Get Price Quote

VSI5X crusher (the latest vertical shaft impact crusher improved from VSI crusher) is necessary crushing equipment used in manufactured sand production line, sand & gravel production plant etc. It is widely used for manufactured sand or artificial sand production. Also, it is the mainstream truing machine for mining and construction industries. Features Dual purpose balk cargo tray - simplicity of operation, quick switchover of feedstock modes. Key parts adopt optimization design - reducing wear and use-cost Rotor optimization design - deepening cavity type to increase yield Elaborately-designed Emission Mouth and Inner Curve - reducing resistance and increasing throughput

vsi crusher

1,250,000 - 2,500,000 Per piece

1 piece (MOQ)

Vertical Shaft Impact crushers are used in secondary, tertiary or quaternary stage crushing ,for the production of high quality manufactured sand, well formed aggregates and industrial minerals, shaping or removal of soft stone from aggregate.

Best Deals from Vertical Shaft Impact Crusher

Vertical Shaft Impact Crusher

2,000,000 Per Piece

Vertical Shaft Impact Crusher

Get Price Quote

Working closely with our customers, and listening carefully to their needs, has led to many new solutions in the design of VSI to improve business for crushing customers. OUR OFFERINGS : Well balanced rotor table fitted with special carbide tips (easy replaceable) for long life Well designed outer ring with anvil or rock - on - rock ports Central shaft fitted with antifriction bearings for efficiently transferring the power, speed to meet the crushing task Optional hydraulic arrangements to lift the top cover for easy accessibility to main crusher parts In the aggregate and quarrying sector, it is used for production of high-quality manufactured sand and premium shaped aggregates. Other areas include aggregates for dam construction, Ideal for various minerals clinker, glass, slag, etc and industrial minerals plants crushing extremely abrasive high-value materials.

Vertical Shaft Impact Crusher

Get Price Quote

Road Paver Finisher, Modular Concrete Mixing Plant, soil stabiliser

Vertical Shaft Impact Crusher

1,500,000 Per Piece

vsi crusher

Get Price Quote

Mining VSI Series vertical shaft impact crusher is designed by reputed German expert of Mining and every index is in world’s leading standard. It incorporates three crushing types and it can be operated 720 hours continuously. Nowadays, VSI crusher has replaced hammer crusher, roller crusher, roller ball mill, becoming the mainstream equipments in sand making business. Pretreatment: Using the hydraulic hammer to crush the big stone into smaller one, and arrange the worker to cut through the long reinforcement to prevent damaging the belt conveyor. Reliable dual pump oil supply lubrication system—stable performance, long life Hydraulic pressure jack device—convenient, timesaving and laborsaving for maintenance Installation mode selection—handy installation, diversified modes, easy to operate Crushing principle selection—impact grinding with superior particle shape Chamber type optimization design——lessening consumption of wearing parts.

Vertical Shaft Impact Crusher

Get Price Quote

Vsi crusher genrally utilize a high speed spinning rotor at the center of the crushing chember and an other impact surface of either abrasive resistance metal or cursher rock Etc.

Vertical Shaft Impact Crusher

Get Price Quote

Ready to use structure. Quick Installation, Immediate operation ( wheel mounted mobile option is also available ), Rock on technology ensures minimum operating costs along with least wear & tear.Low investment. Low downtime for replacement of parts & consumables.

Vertical Shaft Impact Crusher

Get Price Quote

Vertical Shaft Impact Crusher

Get Price Quote

Vertical Shaft Impact Crusher

Get Price Quote

Mobile Vsi Crusher

Get Price Quote

Mobile VSI Crushers are ideal for tertiary crushing and screening applications in quarrying, mining, concrete recycling, infrastructure and construction industries. It is especially used to process raw material to excellent aggregate and sand for railway, highway, freeway and building construction. Processed Materials : Iron ore, copper ore, gold ore and silver ore, zinc ore, manganese ore,limestone、granite、basalt、river stone、coal gangue、quartz. Applications : Mechanism sand, bituminous concrete, metal mine, aggregates shaping Features 1. High capacity2. fine crushing and shape adjusting3. high performance, flexible4. integral crushing & screeing5. belt conveyor self-loaded

Vertical Shaft Impact Crusher

Get Price Quote

US VERTICAL SHAFT IMPACT CRUSHER

Get Price Quote

The three-hole impact enclosed rotor is adopted to realize the crushing and forming of the materials entering the crusher through the principle of stone-hit-stone and self crushing. Meanwhile, crushing and forming of big particle can also be realized.

Vertical Shaft Impact Crusher

Get Price Quote

Details PCL sand making machine is of high-power and low-consumption which is designed depending on several years hard work and study of mechanical mining equipment. Advantage Unique Lining in Impellers and Vortex Crushing Cavity Unique Lining significantly decreases wear parts cost and maintenance workload. During the process the stone rock can form a protective bottom layer which makes the equipment more durable. Low Dissipation Wear Parts Adopting high-quality wear-resistant materials at home and abroad leads to long service life. Hard wear-resistant material small volume light weight easy to replace. Advanced Spindle Design Bearing special installation and advanced spindle design with characteristics of heavy load and high speed rotation without any problem in fine crushing and coarse grinding. Good Grain Shape of Final Products Final products are cubic shape high density and low iron pollution and can be used as stone shaping machine. Working principle Material from the hopper falls into sand crusher and will be divided into two parts by the distributor. One part falling into the high-speed rotation impeller through the middle and accelerated rapidly within the impeller. That acceleration can be up to several hundred times the acceleration of gravity then projecting out from three uniform impeller flow channel at speed of 60-70 m / s; another part of the material falls freely from all around the feeder impact on the vortex branch cavity lining and then will be bounced back to the top of vortex chamber the movement direction would be changed to start moving down on the diagonal; materials emitters from the impeller form a continuous material curtain. Thus materials will be hit rubbed and grinded twice or several times in whirl crushing cavity. Finally crushed materials discharge from the lower discharge port. Throughout the crushing processmaterials impact and crush each other not in direct impact on the metal element but only shock rub and grind the lining thus prolonging mechanical life. Product introduction Production capacity : 10-500T/h Note: this is only an average value and the specific is subject to the clients’actual equipment configuration in site. Processable Material : Limestone river pebble rocks bluestone cobblestone weathered sand basalt granite quartz diabase. Range of Application : mine cement fire-proof materials bauxite corundum glass raw material building sand stone materials and other metallurgy slag. PCL sand making machine is of high-power and low-consumption, which is designed depending on several year’s hard work and study of mechanical mining equipment. This type sand maker absorbed the advanced technology of the same products of Barmac Company of America, and now is of the international level. It plays an important role in crushing minerals into pieces. Since the sand processing machine was put into production in 2001, EMCC has achieved good market share in domestic market, and product performance is tending toward best perfection, deeply trusted by customers. PCL sand making machine, namely Vertical Shaft Impact Crusher, is widely used in all kinds of mineral, cement, corhart, carborundum grain, glass raw material, machine making construction sand, stone stock and all kinds of metallurgy slag, especially carborundum, sintered bauxite, magnesite, and materials with features of very hardness and anticorrosion. And this and making equipment is more productive than other kind of sand&stone crushers.

Vertical Shaft Impact Crusher

Get Price Quote

Vertical Shaft Impact Crusher

Get Price Quote

We are offering vertical shaft impact crusher. vertical shaft impact crusher ( vsi ) is more suitable for crushing mid-hardness materials and high-hardness materials and its product is cubic, and the density of piling up is high and the iron pollution is low. Vertical shaft impact crusher ( vsi ) is widely used in metal and nonmetal mine, concrete, fireproof material, abrasive filler, frit, construction aggregate, sand, metallurgy and so on. it is applied widely for the powder process of mineral product including mental and non-metay ore, fireproof material, bauxite, diamond dust, glass raw materials, archtiectural materials, artificial sand and all kinds of metal ore materials, especially which has more advantages than any other machines in processing the more and most hard materials. features of vertical shaft impact crusher: 1. Standard replacement parts 2. Heavy duty design 3. High productivity 4. Minimum maintenance 5. Safe and user-friendly 6. Cubically shaped product 7. Cost effective 8. Excellent performance and high final fineness 9. Smooth and quiet operation 10. Long service life

Vertical Shaft Impact Crusher

Get Price Quote

Vertical Shaft Impector

Get Price Quote

VSI impact crusher can be used for variety of jobs, including crushing of rock in quarries (limestone, dolomite, sandstone, gravel, etc,) and processing of building waste for recycling (concrete, brickwork, debris, bituminous materials at road reconstruction) Simplified Retro Fitment from Stone on Stone to Stone on metal : Stone on Stone To Stone on metal version can be easily converted by offering anvil Rings & Stone chamber combination which results in higher product yield. This simplified Retro fit can be easily & quickly installed on existing Stone on Stone model without changing the complete machine resulting in differing product needs. Features & Benefits The capacity data is based on computer models using stone with a bulk density of 1.6t/cubic meter. Actual throughput depends on a large number of factors and will vary between feed materials. Technical data and specifications are subject to change without notice.

Vertical Shaft Impact Crusher

Get Price Quote

A superior combination of rotor design & wear material characterizes the SINGH Vertical Shaft Impactor. This combination has proven to be exemplary in improving the product quality as well as improving the capacity. The current and future operating conditions will demand stringent productivity demands. The solution is offered by SINGH V.S.I. Like all other SINGH equipment, the V.S.I has been designed to minimize maintenance and improve and facilitate all adjustment operations. The machine layout has been optimized for compactness. The core objective of our engineers has been to make the machine stronger and more powerful than similar sized machines without affecting the compactness of the machine. Our engineers will help you choose the right rotor configuration along with the right crushing chamber to minimize your crushing costs and improve product quality. The most powerful feature of the SINGH V.S.I. is that you can achieve more reduction in fewer stages thereby you will not only save on capital costs but also on recurring energy costs. Permanent collaboration with the best foundries has ensured superior alloys for the wear material, which drastically reduce your operating costs. The shoes, liners and the impact anvils are made of superior grade alloys, sourced from just the best! For unbeatable performance in secondary or tertiary applications, there is only one choice, SINGH.

vsi crusher

Get Price Quote

Features Reliable dual pump oil supply lubrication system—stable performance, long life Hydraulic pressure jack device—convenient, timesaving and laborsaving for maintenance Installation mode selection—handy installation, diversified modes, easy to operate Crushing principle selection—impact grinding with superior particle shape Chamber type optimization design——lessening consumption of wearing parts. Description TQMC VSI Series vertical shaft impact crusher is designed by reputed German expert of TQMC and every index is in world’s leading standard. It incorporates three crushing types and it can be operated 720 hours continuously. Nowadays, VSI crusher has replaced hammer crusher, roller crusher, roller ball mill, becoming the mainstream equipments in sand making business. Application VSI series crushers are widely used in crushing nonmetal mine, concrete, fireproof material, abrasive filler, frit, construction aggregate, sand, metallurgy and so on. It is the indispensable machine in sand making industry and it is also the most ideal truing machine for mining and construction industries.

vsi crusher

Get Price Quote

SF Flotation Cell, Rod mill, Ceramic Vacuum Filter, slurry Pump

Duromech Vertical Shaft Impact Crusher

Get Price Quote

Features :- 1. Easy portability and quick installation with minimum support structures. 2. Variable capacity models for tertiary applications. 3. Rock-on-Rock technology minimizes wearing of parts, hence minimum operating and wear costs. 4. Consistent product gradation. 5. Low investment. 6. Simple maintenance. 7. Advanced oil lubrication system. 8. Externally Adjustable Feed Tube System. 9. Heavy Duty Pedestal Drive. 10.Adjustable Motor Mounts. 11. Suitable for any type of stone. 12. More cubical crushing compared to any other machine. 13. Special dustproof seal system, outside powder is prevented from entering oil mouth

Vertical Shaft Impact Crusher

Get Price Quote

Jaw Crushers applies compressive force onto material to be crush that may produces flakiness to the material. Flakiness is not permissible after certain extent because it reduces the strength of the material. Maxwell VSI intakes the screen aterial of specified size into the rotor where it is accelerated to high speed. The Material gets high velocity into the rotor and then it discharge from fixed rotor openings and collide with the rocked outer periphery resulting into crushing. Maxwell VSI crushers offers multi-port rotor designs that provide large application range and crushing technology for rock-on-rock reduction. Maxwell VSI can operate on high rotor speed which provides high crushing ratio. Such high crushing ratio enable Maxwell VSI to produce crush send as well.

Vertical Shaft Impact Crusher

Get Price Quote

VSI vertical shaft impact crusher (sand making machine) is our crystallization of diligence and wisdom . Advantage Two crushing ways of “rock on rock” and “rock on iron”. Multiple crushing ways meet the needs of different materials crushing. Dual Pump Design There is only one pump working in normal use. When the value of the pressure and flow rate do not reach the set value or when the first pump fails the second will open automatically to ensure the normal operation of the host. Bearing Bit Thermostat Bearing bit thermostat and pump automatic cycle ensure that the temperature inside the bearing cartridge similar to the oil in the tank to prevent the winter freeze. Hydraulic Arms Hydraulic arm design greatly reduces maintenance costs. Working principle VSI crusher design is based on the principle of mutual crushing and friction in the high-speed movement materials. This type sand making equipment can not only crush stones but also the stones and gravel can be shaped by it. According to feeding method centrifugal impact crusher working form is divided into central feeding and central with cascade feeding; the crush form is divided into “rock on rock” and “rock on iron” according to material compressive strength abradability. So the VSI crusher can be divided into four kinds: “rock on rock” and “rock on iron” with central feeding “rock on rock” and “rock on iron” with central with cascade feeding. Material from the hopper falls into VSI sand crusher and will be divided into two parts. One part passed into high speed rotating wheel to be accelerated and high-speed projectile rapidly impact crushing another part of the material from points around the tray and will be impacted on the vortex branch cavity lining together. Then it will be bounced back to the top of vortex chamberand the movement direction would be changed to start moving down on the diagonal; materials emitters from the impeller form a continuous material curtain. Finally crushed material discharge from the lower discharge port. Product introduction Production capacity : 60-500T / H Note: this is only an average value and the specific value is subject to the clients’ actual equipment configuration in site. Processable Material : Limestone river gravel rocks bluestone cobblestone weathered sand basalt granite quartz diabase etc. Range of Application : Non-metallic minerals building materials artificial sand and a variety of metallurgical slag crushing and shaping VSI vertical shaft impact crusher (sand making machine) is our crystallization of diligence and wisdom . Its integrated design we owe to the technology R&D specialists who personally go to the scene to understand the demand and opinions of equipment operators. By increasing production, reducing wear cost, prolonging maintenance cycle, thus we developed this multi-purpose crusher which has a couple ways of feeding and crushing modes, making it become the preferred device in the fields of stone integer, artificial sand, refractory, ball mill feeding, industrial construction materials processing and so on.

vsi crusher

Get Price Quote

SBM VSI Series vertical shaft impact crusher is designed by reputed German expert of SBM and every index is in world’s leading standard. It incorporates three crushing types and it can be operated 720 hours continuously. Nowadays, VSI crusher has replaced hammer crusher, roller crusher, roller ball mill, becoming the mainstream equipments in sand making business. Features SBM VSI Series vertical shaft impact crusher is designed by reputed German expert of SBM and every index is in world’s leading standard. It incorporates three crushing types and it can be operated 720 hours continuously. Nowadays, VSI crusher has replaced hammer crusher, roller crusher, roller ball mill, becoming the mainstream equipments in sand making business. Features Reliable dual pump oil supply lubrication system—stable performance, long life Hydraulic pressure jack device—convenient, timesaving and laborsaving for maintenance Installation mode selection—handy installation, diversified modes, easy to operate Crushing principle selection—impact grinding with superior particle shape Chamber type optimization design——lessening consumption of wearing parts. Application VSI series crushers are widely used in crushing nonmetal mine, concrete, fireproof material, abrasive filler, frit, construction aggregate, sand, metallurgy and so on. It is the indispensable machine in sand making industry and it is also the most ideal truing machine for mining and construction industries.

vsi crusher

Get Price Quote

vsi crusher

Get Price Quote

SBNITH VSI Series vertical shaft impact crusher is designed by reputed German expert of SBNITH and every index is in worlds leading standard. It incorporates three crushing types and it can be operated 720 hours continuously. Nowadays, VSI Crusher has replaced hammer crusher, roller crusher, roller ball mill, becoming the mainstream equipments in sand making business.