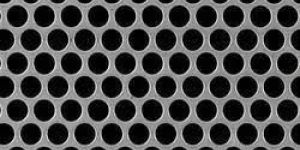

Perforated Sheet

400 / Kilogram

20 Kilogram (MOQ)

Specifications

thickness 1mm 2mm 3mm 4mm 5mm

color black blue green red transparent

feature wear resisting printed adhesive odourless corrugated

description,

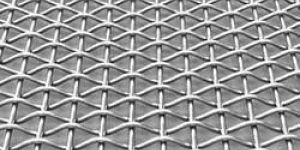

perforated metal, also known as perforated sheet, perforated plate, or perforated screen, is sheet metal that has been manually or mechanically stamped or punched to create a pattern of holes, slots, or decorative shapes. Materials used to manufacture perforated metal sheets include stainless steel, cold rolled steel, galvanized steel, brass, aluminum, tinplate, copper, monel, inconel, titanium, plastic, and more.

The process of perforating metal sheets has been practiced for over 150 years. In the late 19th century, metal screens were use as an efficient means of separating coal. Unfortunately, the first perforators were laborers who would manually punch individual holes into the metal sheet. This proved to be an inefficient and inconsistent method which led to the development of new techniques, such as perforating the metal with a series of needles arranged in a way that would create the desired hole pattern.

Modern day perforation methods involve the use of technology and machines. Common equipment used for the perforation of metal include rotary pinned perforation rollers, die and punch presses, and laser perforations.

Size : 5x8,4x7,3x6,2x5,6x9

Application : Flooring,Outdoor Furnitures,Stairs,Other

Material : Metal,Mild Steel,Steel

Feature : Corrosion Resistant,Durable,Fine Finish,Good Quality,Tamper Proof,Water Proof,Other

Condition : New

Width : 0-500mm,1000-1500mm,1500-2000mm,2000-2500mm

Finishing : Coated,Non Coated,Other

Shape : Rectangular,Square,Other

Thickness : 0.5-1mm,8.5-9mm,7.5-8mm,6.5-7mm,5.5-6mm,4.5-5mm,3.5-4mm,2.5-3mm,1.5-2mm,9.5-10mm

Number Of Flower : Perforated Sheet