Sand Blasting Machine

Request for Price

1 Piece (MOQ)

What is a Sand Blasting Machine?

Sand Blasting Machines can be described as an effective means of treating the exterior surface of a product, smoothening it and for removing all extraneous matter.Sand Blasting machines are used to remove rust and corrosion and they are highly effective in treating rough surfaces of metals and non metals. A Sand Blasting Machine can either be stationary or portable.

Aerowheel is an experienced Sand Blasting Machine Manufacturers in India and it has successfully delivered it to many of its clients as per their specifications.

The process of Abrasive Blasting began in 1904. The Sand Blasting Machine Manufacturer mostly uses silica sand which is employed as an abrasive for the sand blasting procedure. A Sand blasting machine for sale is also used to devise and clean the exterior surface of the metal.

Sandblasting is the most effective kind of surface preparation and we offer sandblasting equipment to meet all of your needs.

Sand Blasting Machine Price depends on factors such as amount of sand poured, sterilization rate, working method etc.

Our Sand Blasting Machine prices are effective and you can trust their performance levels for decades.

We deliver different types of Sand Blasting Machines such as Portable Sand Blasting Machines, Sand Blasting Cabinets, Cement Blasting machines, Tumblast, Abrasive Blasting Cabinets, Tunnel Type Shot Blasting Machines and many more.

While blasting through Sand blasting machines,Shot Blasting Machine, Grit Blasting Machine, Abrasive Blasting Machine, Thermal Spray Gun, Arc Spray Gun, etc. we should carry some protection measures otherwise it will be harmful to the person who is doing the blasting. Here are some safety wears:

Air Blaster Helmets.

Air Conditioner.

Air Breather.

Workers Suits.

Hand Gloves.

Gumboots.

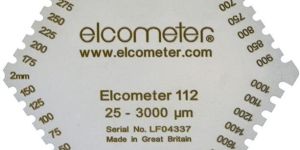

Sandblasting equipment includes systems or machinery, and components for projecting blast media against a part's surface to abrade, clean, or modify the surface. Sand, abrasive, metal shot, and other blast media are driven or propelled using pressurized water, compressed air, or a blast wheel.

Applications of Sand Blasting Machine:

Paint and Rust Removal

Tool Cleaning

Shaping Small Parts

Art Design

Street Cleaning

There are different types of sand blasting machines that come in different sizes and specifications in India. Each sandblasting machine is used for a different sandblasting purpose, uses different blasting media and has its own air compressor requirements.

Sand Blasting Sand and Abrasive Material is reusable. In order to reuse it, one needs to have an adequate facility that enables efficient collection of used sand and abrasive material. To make your machine environment friendly, install a dust collector along with the machine. It keeps the environment clean and one can easily reuse the collected sand.

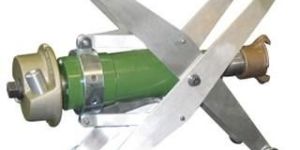

The Shot Blasting Machine makes use of a mechanical method of propelling abrasive media using a radial wheel to remove a layer of the surface and contaminants from the surface of metal and steel products.It cleans and descales the surfaces, enhances paint adhesion by adding texture to the surface of metal products, efficiently reduces maintenance costs by increasing the life of the coating Shot blasting Machine process. A shot blasting equipment machine is used to remove unwanted corrosion and metallic waste on the surface of finished goods.

A portable sand blasting machine is a machine that can be transferable from one area to another effortlessly. Portable sand blasting machine in India is the practice of extraordinary quickness impelling a stream of blasting sand against an exterior surface under extremely high influence to smooth a rough exterior surface, roughen a smooth covering or eliminate the loose scraps from the metal exterior surface.

Sand is handled to be the common generally applied material, but since the lung ailment makes happen by extensive inhalation of the fine dust generated by sand, other substances are now employed in its place such as copper slag, glass beads, aluminum oxide, low carbon cut wire shot, steel grit etc. These all are known as abrasive media.

Aerowheel has a niche in developing Sand Blasting Machines with their experience and interactions with clients all over the World. You can learn about other factors that render a Sand Blasting Machine useful and determine factors that cause the price of the machine to vary by contacting our team.

Application : Sand Blasting

Country of Origin : 220V

Automatic Grade : Automatic

Power : 1-3kw

Driven Type : Electric

Brand Name : Aerowheel Surface Finishing

+1

+1

+4

+4

+3

+3

+4

+4

+1

+1