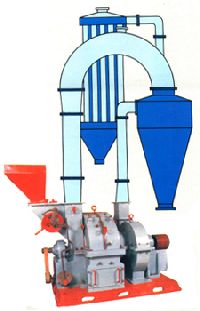

Spice making machine

Get Price Quote

Manufacturer of SPICE Mills with integral separator provide an automatic dust free complete system for medium to fine grinding of wide variety of spices, ayurvedic and other foodstuffs. They are suitable for handling chilies, turmeric, coriander, mix SPICE, herbs, roots, leaves, saw dust, cattle feed, bran, filtered cakes, sugar and other foodstuffs. manufacturer of The SPICE MILL is multipurpose economy mill for spices grinding, which can handle lumpy and irregular size materials to produce coarse to medium fine powder. The material is fed to the mill through manual feeder where it is ground by Impact, Shearing, Crushing, and Auto collision of materials. The person feeding the material controls feeding to any desired rate. The material from the feeding hopper is fed directly in the grinding chamber and is conveyed to the periphery of the chamber through a series of beaters, thus gradually reducing them to the desired fineness .The mill is a swing hammer type machine incorporating a centrifugal blower for delivering ground material to cyclone collector. Sieve of required mesh is placed at the bottom of the chamber and allow the pulverised material to be ejected to centrifugal blower. Centrifugal blower makes timely and instant removal of ground material being discharged through fineness controlling sieve at the bottom half of the mill.

Hammer Mill Pulverizers

Get Price Quote

Hammer type mill for grinding minerals, chemicals, food items, tamarind seed, saw dust, coconut shell, agarbatti raw material, fullers earth, plaster of paris (calcined gypsum), hydrated lime, herbs etc.

Best Deals from Spice Processing Plant

impact pulverizer machine

Get Price Quote

Impact Pulveriser's are impact type, high speed, air swept, swing hammer type, multipurpose grinding mills capable of grinding soft to medium hard minerals & chemicals upto the hardness of 2.5 - 3.0 Mohs. The Pulveriser is supplied with a hopper below which is a Star Feeder actuated by a Pawl & Ratchet Mechanism. Fine Grinding is achieved by compression, shear, abrasion, attrition and impact of Hammers on the materials against the replaceable Radial Liners. Heavy Duty Construction Low Power Consumption Better Fineness control Automatic Screw Feeder

Impact Pulverizers

Get Price Quote

1 Set(s) (MOQ)

We are offering impact pulverizers. singhasini manufacturer of impact pulverisers are high speed, air swept, swing hammer type, multipurpose grinding mills capable of grinding soft to medium hard minerals & chemicals up to the hardness of 3.5 � 4.0 moh�s such as minerals, bentonite, clays, limestone, neeru, dolomite, coal, bauxite, barytes, gypsum, china clay, soap stone, calcite, pyrophillite, mehandi, spices etc. The main mill is equipped with a hopper below which is the star-feeder actuated by pawl & ratchet mechanism. The fine grinding is achieved by compression, shear, abrasion, attrition and impact of hammers beaters on the materials against the replaceable serrated striking plates. The strong suction blower sucks the pulverized product and the air stream inside the mill carries the result product. In between the fan and the grinding chamber (having beaters hammers) is the whizzer classifier consisting of blades with tips tapered to conform the contour of whizzer classifier cone. Counter current is set up at the periphery indicated by arrows; it rejects the coarse material back to the grinding chamber for re-grinding. Clamping the whizzer clamp at a suitable position can control fineness. The entire wearing parts consisting of grinding chamber, whizzer classifier and blower are lined with replaceable lining plates. star features: �lower power consumption. �fineness control. �automatic feeder. �low operation & maintenance cost. �high grinding efficiency. �whizzer classifier. �open circuit grinding. �trap iron pocket. �high efficiency cyclone separator. �tubular air bag filter. �continuous silica separator. �high reduction ratio. �heavy duty construction. �sixty year of experience.

Pin Mill Machine

Get Price Quote

Pin Mill Machine, industrial mills, Eccentric Sieve Machine