Hot Dip Galvanizing Plant

Get Price Quote

Planning & construction of tank system with fume exhaust system. Robust design of tank made out of Industrial Thermoplastic. Environment friendly Fume Extraction System, avoiding corrosion of surrounding steel construction, cranes and roof structure. Plastic Tanks available in flat pack modules (reduced volume) Heating and circulation system available. (optional) Tank made from Industrial Thermoplastic and welded with state-of-the-art hot gas extrusion welding process and stress relieved. Modules assembled and welded at site for easy transportation.

Pre-Treatment Plant for Strip Galvanizing Plant

Get Price Quote

We are a dynamically developing company that has evolved itself as a prime manufacturer and exporter of superior range of multifarious products such as pickling tank for strip galvanizing plant, pretreatment plants, pickling tank, acid fume extraction system and zinc white fume extraction and anti-corrosive equipment made from various industrial thermoplastics. We have been constantly innovating and improvising on quality of products to confer to the industry norms and standards. In pretreatment plant having all surface treatment tanks with all kind of accessories. • degreasing tank • rinsing tank • pickling tank • flux tank • quenching tank • stripping tank available accessories on request : 1. level indicator 2. heater 3. liquid circulation 4. air agitation 5. protection plate 6. heater protection plate 7. spreader (specially designed for tube industries) 8. rib 9. jig resting arrangement on tank 10. suction duct with slot 11. connections 12. lid with automation technical specification : above all tanks are made out from polypropylene non sticky material corrosion free, long lasting, design on rita (roechling integreted german tank building assitant) software. Weld on german wegner welding machine according to dvs norms therefore leak proof and long lasting. Advantage of all tanks • enviro friendly • easy to move • corrosion free • long lasting • leak proof • corrosion free • maintenance free • cost saving. Corrotech expertise : 1. custom design according size & weight. 2. fold bending 3. butt fusion welding technology 4. design on tank design software rita 2.5 benefit to uesr less pickling time. Less pickling tank increased productivity. Low production cost & rejection. Better pickling quality. Correction resistant. Low production cost & rejection.

Best Deals from Galvanizing Plant

hot dip galvanising plant

12,000,000 - 20,000,000 Per Piece

1 Piece (MOQ)

Turnkey Galvanizing Plant

40,000,000 Per Set

1 Piece(s) (MOQ)

We are capable of handling both automated inbound and outbound consignments, we have excellent warehousing solutions available. We keep the extensive array of products sorted to make sure that the delivery commences thoroughly. We use superior-grade packaging as barrier protection for our products against dust, moisture, mechanical damages and logistical jostling. Our products packaging is premium. As a dependable name from Navi Mumbai (India), we make available our products to every nook and corner ensuring complete customer satisfaction. To offer complete satisfaction to the clients, we ensure that we deliver only faultless range of products and thus we store the entire lot in our secured and capacious warehousing unit. PRODUCT SIZE: (L) 0.8 meter x (W) 0.8 meter x (H) 0.6 meter to (L) 12 meter x (W) 2.0 meter x (H) 3.0 meter {as per client requirement} CAPACITY: 500 kg per hour to 15 ton per hour {as per client requirement} FIRING OPERATION: electricity, furnace oil, diesel or light diesel oil, natural gas butane gas, LPG {as per client requirement} AUTOMATIC GRADE: Manual, Semi-Automatic, fully automatic POWER CONSUMPTION: 10-200 kW as per capacity DESIGN TYPE: Customized FEATURES: Industry approved design Toughness Rust free Accurate dimensions Strong structure Smooth workability Longer service life Minimal maintenance High performance Easy installation Innovative design The galvanizing plants for general jobbing have been designed for the galvanizing process of various shaped material. The dimensions of these plants are variable as they depend by different factors: Kind of materials (road barriers, poles, cable channels etc.) By material dimensions (maximum overall dimensions of the piece to be galvanized) Yearly quantity, tons per year. According to the Customer needs different layout type and kind of plant are possible (manual, semi-automatic and fully automatic).

wire galvanizing plant

Get Price Quote

Galvanized Wires offered by us are soft and used for earthing purposes, manufacturing of many wire products, such as Chain link, Stay wire, Barbed wire, Wire meshnetting etc. We have a wide variety, range, and quality of galvanized wires for different purposes and needs. Plants are run under the supervision of experienced technical team facilitated with lab support to ensure consistency in quality. We have three galvanizing plants using different techniques to meet the demand in the market with the weight range from 25 kgs to 600 kgs packed in rolls as per customer requirement.

Galvanizing Plant

Get Price Quote

we are engaged in the manufacturing, exporting and supplying of industrial galvanizing plant which is manufactured from the best quality raw material. Our industrial galvanizing plant can be customized as per the client’s specifications. We offer state-of-the-art galvanizing plant which is available in various sizes and equipped with latest pickling system and fume extraction system. Our galvanizing plant is corrosion-resistant, easy-to-maintain and cost-effective and is designed as per emission regulations. features fumeless picklingdifferent ranges in sizecan be customizedmanufactured from best quality raw materialcorrosion resistantavailable at competitive prices

Galvanizing Plant

Get Price Quote

1 Piece(s) (MOQ)

We are offering steam boiler burner, dual fuel burner, gas burners galvanizing plant, Kettle, Steam reservoir

hot dip galvanising plant

Get Price Quote

Hot dip galvanizing on the surface of Steel, aluminium and iron metal with zinc coating for long lasting and quality finishing by professionals as per the client's need and demand. Hot dip galvanizers used in the processing of galvanizing by our organization as Precimax online to deliver the best solutions that's why we are appreciated by our clients and clients positive feedback is our main assets. Galvanization is the process of coating defensive zinc coating on steels and irons into classify to find rusting, we take all cautions and supply and offer best to hot-dip galvanising plants since 1962 over more than 400 clients. Galvanizing equipments is the total option of products which is included as hot dip galvanising crash guard and guard rail, Galvanizing Plant, General Galvanizing Plant, Galvanizing Plant for Radiator and Transformer, Galvanizing Dryer, Wire Galvanizing Line. Hot dip galvanising is design and developing for the utilizing high grade of raw materials and heavy hot dip Galvanizers machine in harsh conjunction with the industry set the norms and levels. Hot dip Galvanizing is usually very well tested in unique details in order that defect free products usually are sent from consumers' place. Hot dip Galvanizers give some advantaged like limited pickling time period, short manufacturing charge, reduced creation price tag, improved productivity etc.

hot dip galvanising plant

Get Price Quote

Plast World introduce ourselves as a Leading manufacturer, Supplier and exporter of a comprehensive range pickling tanks such as pickling plants for galvanizing tower , pickling plants for transmission tower, pickling plants for S.S. M.S. Pipes ,Tubes , Wire coils, Stripe etc.We design pickling Tanks that are used by galvanizing plants manufacturers for usage in high tension transmission Tower , poles, Pipe Cable Trays ,Grating , Guard, Tails, Railing and other steel items.

wire galvanizing plant

Get Price Quote

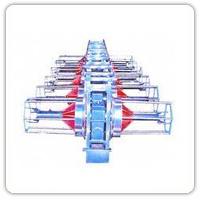

We hold expertise in manufacturing and supplying an exclusive range of Wire Galvanizing Plant. These products are fabricated using superior grade factor inputs, sourced from the reliable and certified vendors of the market. Our product range is extensively used for various industrial purposes and is widely appreciated by our clients due to its durable finish standards, high tensile strength and reliability. Our valuable clients can avail these products from us at the most affordable rates. The use of inverted vertical drawing machine is increasing day by day for drawing cold heading quality wire, high carbon wire, stainless steel wires & various kinds of alloy wires of thick sizes and specially for small quantity each sizes with bigger coil weights. The machine can increase the efficiency of work to a large extent as the drawing is done from coil to coil & drawn wires are directly wound on carries with are taken as it is for further in plant use or large coil despatches.In case of wires size over 20mm productivity can also be increased with inline type cutter pointing machine and horizontal arm type revolving pay of with push feeding system.

Wire Galvanising Plant

Get Price Quote

1 Container (MOQ)

Cold Dip MS Wire Galvanizing Plant

60,000,000 Per unit

galvanizing equipment

Get Price Quote

Haryana Chemical Industries (HCI), an ISO 9001:2000 certified company, is one of India's leading manufacturers of Zinc Chloride and Galvanizing chemicals for the Galvanizing Industry. Founded in 1971 by Shri K.L. Kochar, We have over the years, grown from a Zinc Chloride commercial grade manufacturing company to manufacturers of a complete range of Zinc Chloride, Galvanizing, Galvanizing Flux, Hot Dip Galvanizing and Galvanizing Chemicals with wide applications and world-wide sales.

hot dip galvanising plant

Get Price Quote

Hot Dip Galvanizing is the process of applying a zinc coating to fabricated iron or steel material by immersing the material in a bath consisting primarily of molten zinc. The galvanizing process has a distinct Advantage providing corrosion protection.

Galvanizing Plant

Get Price Quote

Galvanizing plant ranging from 0.5 m to 13 m long manufacturer with pp tanks and pollution control equipments.

wire galvanizing plant

Get Price Quote

Our organization specializes in offering a superior range of Wire Galvanizing Plant to our clients. These machines are facilitated with latest pickling system and fume extraction system and are also available in various sizes ranging from 5mm to 0.4mm. Our range of machines is ideal for M.S. and H.C. steel wires, electro and hot, and deep wire galvanizing plants.

Hot Dip Galvanizing Plant

Get Price Quote

Arvind Corrotech is a leading supplier of turnkey hot dip galvanizing plants that guarantee great performance, productivity and efficiency. Starting from scratch by providing a customized design to commissioning, we get along with you in the process to set a high-performance galvanizing plant.

Hot Dip Galvanizing Plant

3,200,000 Per Units

1 Units (MOQ)

Pole Galvanizing Plant

10,000,000 Per Units

Galvanizing Plant

Get Price Quote

Hot Dip Galvanizing is a factory controlled metallurgical combination of zinc and steel that provides corrosion resistance in a wide variety of environments, Hot Dip Galvanizing protects steel from corrosion in two ways. It provides cathodic protection and barrier protection. For over 150 years Hot Dip Galvanizing has had a proven track record of protection in a myriad of applications.In this step, the material is completely immersed in a bath of a minimum of 98% pure molten zinc. The bath temperature is maintained at about 4500C. Fabricated items are immersed in the bath long enough to reach bath temperature. The articles are slowly withdrawn from the galvanizing bath , and the excess zinc is removed by draining, vibrating, andor centrifuging. The steel then goes into a dilute chromate quench giving your product a longer lasting luster.

wire galvanizing plant

Get Price Quote

Buyers can consider us, if they are looking for a cost effective and excellent quality range of Wire Galvanizing Plant. The offered product range is designed and developed by using the top-notch quality material, thus ensures the quality. Sturdiness, longevity and cost effectiveness are some of the key attributes, which make our Wire Galvanizing Plants high in demand among the global buyers.

Hot Dip Galvanizing Plant

Get Price Quote

We are offering hot dip galvanizing plant. the keya plast can supply as per your requirement with pickling plants heating system, protection bar against damage, fume exhaust & scrubbing system, hood, ducting, chimney & canopy, pipe separator system in tank, load hanging system on tank, tank covers / lid, integral fume ducting, acid circulation system, installation / stat-up / training, etc. the pickling tanks are used for galvanising pipes & tubes, wires & rods, bars & profiles, sheet, strip & coils, transmission tower structure, rcc tmt rebars, highway guide rails, electric poles, electrical overhead hardware, grating, cable trays, wire ropes, etc. pickling tanks used in galvanizing plants, hot dip galvanizing plant, tube & pipe galvanizing plant (stainless steel & non-ferrous), wire galvanizing / plating line (batch/continuous), strip/coil galvanizing line, electroplating and anodizing tanks galvanizing plants, pre & post treatment plants, degreasing & galvanizing lines, passivation & galvanizing lines. galvanizing plant hot dip galvanizing plants hot dip galvanizing with acid pickling tanks

Galvanized Climbing Equipment

45,000 Per Piece

1 Piece(s) (MOQ)

Hot Dip Galvanizing Plant

Get Price Quote

We offer hot dip galvanizing plant. Ferrotherm designs galvanizing furnaces with ‘high velocity burners’ that have long lasting proven performance on delivering high production volumes, low fuel & zinc consumption, high kettle life and requiring less maintenance. The furnace could be designed as dual fuel, oil only or for gas only as fuel. The furnace contains full control trains mainly equipped with controls, safety solenoid valves, piping & fittings imported from uk, germany, hungary and italy. the furnaces are quipped with pulse fired high velocity burners that fire high-off or high-low to control temperature input. Burners are at or near their maximum firing rates when “on.” therefore, they yield the highest possible convective heat transfer, which continuously moves the products of combustion through the entire furnace resulting in excellent temperature uniformity.

Hot Dip Galvanizing Plant

Get Price Quote

Since our inception, we are instrumental in offering premium quality Hot Dip Galvanizing Plant. The offered galvanizing plant is meticulously tested on various quality parameters and is widely demanded in various industries. Provided galvanizing plant is manufactured by utilizing optimum quality raw material and the latest technology at our manufacturing unit. In line with the international standard, we provide the entire range in various customized options and at affordable prices.

Galvanized Wire Plant

Get Price Quote

Hot Dip Galvanizing Plant

Get Price Quote

Reduces Maintenance. Increases life of Products. Cuts off Painting costPipe. Plates. Poles. Metal Beam Crash Barriers. Tubes. Nuts & Bolts etc.

Galvanizing Plant

Get Price Quote

The manufacturing process in nutshell can be described as under: The structural steel grating for galvanizing are procured. The steel articles are dipped into "Caustic Soda Solution" for "Degreasing" The load is rinsed in "Rinsing Tank" containing clean water The load is then preserved in "Pickling Tank" containing HCL 10-12% for first pickling Second pickling is performed in "Second Pickling Tank" which contains HCL - 10-32% The load is again rinsed in "Rinsing Tank" containing clean water Next step is "Pre-fluxing" wherein the material is dipped in "Pre-Fluxing" tank containing "Zinc Ammonium" The load is then dipped into molten zinc at 440-460 degree Celsius which is termed as "Hot Dip Galvanizing" The material then is "Quenched" by passing through running water The material is due for dispatch after "Passivation" and inspection formalities.

wire galvanizing plant

Get Price Quote

We are offering wire galvanizing plant. High hardened adjustable rolls. Shearing attachment (optional). Hand operated pointers are also available.

Hot Dip Galvanizing Plant

Get Price Quote

hot dip galvanizing plant oil removal from the surface of steel, It is immersed in acid base degreaser.To clean the surface of carry over salts for effective acid cleaning.The rust scale & mill scale are removed from the surface of the steel by passing it through 15 to 20% conc. HCL.