Variable Frequency Drive

The company is a highly trusted Manufacturer & Exporter of Variable Frequency Drives. The company has recently tied-up with M/S Crompton Greaves as a channel partner for all their electrical products along with Variable Frequency Drives. Features The AC Variable Frequency Drive is specially developed for constant/variable torque applications like pumps, fans, compressors, blower etc. The process is protected from damage and downtime and you will benefit from reduced installation, energy and maintenance costs. Efficient & Protective Starts & Stops : Efficient and protective starts are ensured with Variable Frequency Drives. Reduced start currents result in smaller fuses, cables and energy bills. Torque can be boosted to overcome initial peak loads. Integrated vector braking ensures quick and controlled stops, increasing productivity and safety. Optimized Operation & Full Control : The direct torque control reacts extremely quickly and eliminates disturbances due to abrupt load changes. A built-in shaft power monitor and a unique Load Curve Protection function protect your process by immediately detecting any situation that could cause inefficiency or damage. Early warnings and safety stops allow preventive action. User-Friendly and Reliable Operations : Operation parameters can be set in your own process units � m/sec, tons/hour, cycles/min etc. � making monitoring easier and more reliable. The removable control panel has a copy function for transferring settings to other Variable Frequency Drives. The user can switch between local and remote control by the push of a key on the control panel. The virtual connection of logical functions, comparators and timers means no cables or external I/Os are required. Cost-Efficient & Flexible Installation : The compact standalone 2.5-250 A units are IP54 classified. The robust steel construction can be installed close to the application, which saves the cost of cabinets and long motor cables. The 300-1,500 A units can be mounted in compactly designed IP54 cabinets. Simplified Maintenance : Should a process problem occur a full status report will be generated. The users can quickly identify the cause and take corrective measures. Maintenance is simplified because of easy accessible mechanical parts and fold-out power modules. Options The user can customize the Variable Frequency Drive in terms of the functionality and ensure full utilization: Crane Control : A crane I/O expansion board offers efficient riding, lifting, and speed control, and a safety system that activates the mechanical brakes should dangerous loads be detected. Shorter Braking Time : For extremely short braking time a brake chopper is available as a factory-installed option. It is used in combination with brake resistors dimensioned according to the specific application demand. Communication : Communication options include field bus communication via Profibus and DeviceNet, Industrial Ethernet communication via Modbus/TCP and EtherCAT, and serial communication via RS232 or RS485 with Modbus RTU. Motor Protection : PTC and PT100 sensors can be connected to control motor temperature and give process feedback without using a transmitter. Encoder : An encoder can be connected for more accurate speed control or for increased safety through deviation control in crane applications. Safe Stop : This option board offers protection from unexpected start during mechanical maintenance, in accordance to the EN954-1 Category 3 standard. No contactor is required. Liquid Cooling : Units from 90 A can be provided with liquid cooling. This allows you to reduce operating and maintenance costs, and the cabinet can have a protection class higher than IP54. EMC Protection : A first environment category 2 EMC filter is available as a factory-mounted option. Reduced Harmonic Distortions : A 12-pulse rectifier offers a cost-efficient reduction of harmonic current distortions. It reduces power losses in equipment such as transformers and conductors, and eliminates the need to over-dimension these components. Standby Supply : Makes it possible to supply the control circuits via an external 24 V AC/DC supply to maintain communication and set up the system when 3-phase mains are not connected. Provides communication backup if 3-phase main power supply.

...more

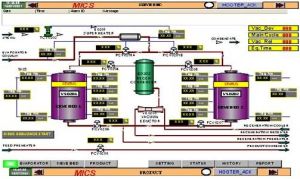

sugar plant automation

We are equipped with years of experience in making sugar Mill Automation on turnkey basis with help of Honeywell make PLCDCS and Field Instruments for the various clients. Our highly technical staff is the main source of power behind our every successful endeavor. We provide All type of Automation for Sugar Plant Automation or Refinery processing plants with excellent services and with affordable prices. Automation systems for sugar plant •Auto Cane Feed Control System (DCSPLCCONVENTIONAL) •Milling Control System (DCSPLCCONVENTIONAL) •Mill Over load Control System (DCSPLCCONVENTIONAL) •Mill D. Chute Flapper Control (DCSPLC). •Imbibition Control System (DCSPLC). •Differential Pressure Control System (DCSPLC). •Automation of PAN Feed Control System (DCSPLC). •Boiler Automation Control System (DCSPLC). •Auto Lime Dosing System (DCSPLC). Features : •Temperature Indicator. •Roller Lift Indicator (Digital). •System Flow Meter cum Totalizer. •Water Flow Meter With Totalizer. •Juice Flow Stabilization System (DCSPLC). •Automation of P.R.D Station (DCSPLC). •Automation of De-Super Heating System. •Automation of Molasses receiving Tank (PLCDCS based Three Loop Control System) •Condensate Water Conductivity Control System. •Mill House Bearing Temp. Indicating System. •Centrifugal Machine Automation (DCSPLC).

...more

PRDS Station Automation

The company is a highly trusted Manufacturer & Exporter of PRDS Station. Fabricated with the help of the best techniques and concepts of engineering and assembly, these PRDS Stations provide optimum pressure reduction as well as temperature control. The perfect design of the PRDS Stations ensures the best performance and the safety of its use is guaranteed as well.

...more

Prds Station

The company is a highly trusted Manufacturer & Exporter of PRDS Station. Fabricated with the help of the best techniques and concepts of engineering and assembly, these PRDS Stations provide optimum pressure reduction as well as temperature control. The perfect design of the PRDS Stations ensures the best performance and the safety of its use is guaranteed as well.

...more

Power Plant Automation

Our services related to power plant automation are just impeccable and reliable. Every customer can truly rely on us for their whole Power Plant Automation System or electric power plant automation. Our Services are available on competitive prices with the back support of efficient professionals. We are one of the major manufacturers who deals in power plant automation services. We also provides all important Parameters display on PC Through Third Party communication on DCS, like power generation, distribution, KW, AMP. VOLTAGE, FREQUENCY, Steam Flow, Steam Tantalize, Turbine Bearing Temperature, Pressure, Turbine RPM etc. Three-Element Drum Level Control-: In most drum level control applications, the two-element drum level control will maintain the required water /steam interface level-even under moderate load changes. However, if an unstable feed water system exists exhibiting a variable feed heater-to-drum pressure differential, or if large unpredictable steam demands are frequent, a three-element drum level control scheme should be considered as implied from the above information, this control strategy supplies control of feed-water flow in relationship to stream flow. The performance of the three-element control system during transient conditions makes it very useful for general industrial and utility boiler applications. It handles loads exhibiting wide and rapid rates of change. Plants which exhibit load characteristics of this type are those with mixed, continuous, and batch processing demands. It also recommended where normal load characteristics are fairly steady; but upsets can be sudden, unpredictable and/or a significant portion of the load. Feed water Control The basic control strategy implemented is a three-element system using drum level, steam flow and feed water flow to regulate the feed water control valve. Both accuracy and stability are improved through the addition of density compensation calculations for both drum level and steam flow. Since flow measurements are typically inaccurate at low values, feed water flow is regulated only on drum level (single element control) during start up and low load operation. The transfer between single and three-element operation is of course both automatic and bump less. Steam Temperature Control The Super heat steam temperature control loop is straightforward, regulating the superheat spray water/air by control valve to maintain the main steam outlet temperature. For more dynamic steam temperature circuits, temperature outlet Temperature is also measured and controlled. Furnace Pressure Control The furnace pressure control loop regulates the ID fan inlet vanes to maintain the furnace pressure set point. The furnace pressure signal is the process variable for the furnace pressure controller/PLC, and the ID fan is operated in coordination with the FD fan. Like the FD fan, appropriate interlocking logic is provided for the ID fan inlet vane for use during starting/stopping of the fan - also per NFPA requirements. Steam Header Pressure Control The Steam Header pressure control system monitors the common steam header pressure to generate a load demand for each of the boilers. To provide stable control and uniform response the control system recognizes each boilerâ��s contribution to the steam load and its ability to respond to load demand requests. Combustion Control Combustion control regulates the fuel and air for the boiler, making it the most complex and important of the control loops. The fuel/air mixture must be just right under all dynamic load conditions. Too much air results in decreased efficiency, while too little air is unsafe and even less efficient. To insure the proper ratio of fuel and air, the controls incorporate both fuel/air cross limiting and O2 trim. Power Solution 1 Unified Energy Solutions Increase in combustion efficiency Enables operation with optimal excess air Emission limits (NOx, CO) Dynamic coordination of air/fuel ratio Reduced life consumption Thermal stress monitoring system Better dynamic performance Predictive control (responsiveness) Range control (stability) Soot blowing optimization Advanced temperature control 6 Total Plant BLR Reporting and Data Modules Build hourly, shift, daily, weekly, monthly and custom operating reports Print, save or page reports based on event triggers, schedule or on demand

...more

Power Control Panel

We offer power control panel. Our services related to power plant automation are just impeccable and reliable. Every customer can truly rely on us for their whole power plant automation system or electric power plant automation. Our services are available on competitive prices with the back support of efficient professionals. We are one of the major manufacturers who deals in power plant automation services. We also provides all important parameters display on pc through third party communication on dcs, like power generation, distribution, kw, amp. Voltage, frequency, steam flow, steam tantalize, turbine bearing temperature, pressure, turbine rpm etc. Power solution 1 unified energy solutions •increase in combustion efficiency •enables operation with optimal excess air •emission limits (nox, co) •dynamic coordination of airfuel ratio •reduced life consumption •thermal stress monitoring system •better dynamic performance •predictive control (responsiveness) •range control (stability) •soot blowing optimization •advanced temperature control

...more

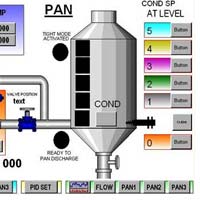

Pan Automation

Pan automation provided by our company is excellent on its every unique aspect. It performs all its functions in stipulated time period and with much more reliability. Our pan automation system is superiorly well performed as compared to other pan automation services. We would like to introduce ourselves as the leading pan automation manufacturer and exporter based in India.

...more

Molasses Receiving Tank

We are one of the major molasses tank manufacturer and suppliers in India that deals in Molasses Tank and Molasses Receiving Tank. Integrated with exceptional features it performs its each and every task promptly and deliver only optimum results to its customers. No doubt, you will get all the outstanding results right after their installation.SALIENT FEATURES : Maintain the temperature of conditioner tank at set valve. Control the conditioner tank over flow. Maintain the brix in conditioner tank. Mixing the water percentage as per requirement of the brix in conditioner. M.R.T. over flow totally (100%) avoided. Man power minimizesLesser consumption of steam.

...more

Milling Control System(Turbine/DC Drive Speed Control)

Milling control system(Turbine/DC Drive Speed Control) is basically designed for controlling and achievement of the followings: Enhance the juice-extraction. Optimize moisture and bagasse pol. Avoid overloading of the mill motor under varying cane feed and the quality of cane. The milling control system (MCS-Motric) monitors load of the individual mill D.C. drive and monitors the speed of D.C. drive automatically; according to load by means of D.C. drive reference voltage (0 to + 10v).The milling control system eliminates the operator½½s fatigue and engineer½½s constant vigil by maintaining a constant load to individual mills under varying conditions.The speed of D.C. drive is increased or decreased according to fiber load and the preset armature current of D.C. drive. D.C. drive speed is controlled within the required speed limits, which is preset for optimum operation.It is highly reliable, accurate & stable instrument. These features are achieved by using ultra precision amplifiers, high resolution stable multi turn potentiometer, wave soldered glass epoxy masked / lacquer coated P.C.B stick quality control and inspection procedure at various stage of production.Other salient features are the usage of single sided P.C.B. along with elimination of connectors, which usually give contact problems and use of well-proven design and components.Milling Control (Turbine) SystemMicro control system consists of transmitters for pressure, level and the necessary hardware/electronic circuitry forming required loops for turbine speed control based on parameters of chest pressure and chute level. Micro control system regulates the mill speed automatically to maintain the desired.ADVANTAGES Following are the advantages from this system Better efficiency in terms of mill juice extraction. Optimization of bagasse moisture and bagasse pol. Better control over the working of mills. Although system is not designed to increase the crush rate, but obviously when shortcomings of manual operations are eliminated, increase in out put is definitely achieved. The most important feature of the MCS is that the constant jerks on mill motor are smoothened out which in turn increases the fluctuating nature of current is also reduced. OPERATIONAL FUNCTIONS The armature current/chest pressure of D.C. drive/turbine is measured by a C.T/P.T. which gives very accurate and error free measurement of load current. The logic software of MCS (Motric) monitors the load and gives the command to the reference voltage of D.C. drive. Maximum and minimum speed is restricted with the help of high and low limit set; MCS vary the speed of mill drive within the band of set high-low limit. Once the desired load is adjusted, the system does not require any manual supervision. Auto/Manual switch is provided on the console to operate the system in Auto mode or Manual mode. For manual mode of operation, mouse provides click to increase or decrease the speed of D.C. drive respectively.

...more

Mill Overload System

The Mill Overload System is a device to be connected with A.C.F.C. for regulating the MILL LOAD & CARRIER SPEED and it�s objective to achieve the following : Constant load shall be maintained on 1st mill. Maximum extraction shall be achieved. Smooth crushing and proper feeding shall be achieved. Boiler efficiency shall be improved. Extreme loading / Hunting of turbine shall be eliminated. Chest pressure range can be set from the operator control console. SENSING PARAMETER: - Chest pressure of mill turbine. Chute level sensing (optional). Though the 1st mill overload system work in accordance with A.C.F.C. But in case need arises it warranted for ONE-YEAR trouble free warranty Including free replacement of parts.

...more

Juice Flow Stabilization

Salient Features Their controls the uniform juice flow and set level of juice tank by feed back signal to ACFC system (Mill House).It provides uniform and stabilized juice flow to process to ensure uniform juice heating.It maintains PH almost constant sulphited juice.It improves juice clarification significantly.It provides better mud setting.It improves raw juice pump workings.It stabilizes the boiling house process in total.

...more

Imbibition Control System

We are a Manufacturer & Exporter of Imbibition Control System. Salient Features Improves Mill Extraction. Regular quantity of imbibition water even under varying condition of cane type. Eliminates dry milling condition. Checks wasteful addition of water during poor feeding. Control & maintain uniformity of bagasse moisture. L.M.J. Brix is maintained steady & uniform. Reduces pol loss in bagasse. In case of Mill stop imbibition water automatically stop.

...more

honeywell plc

We offer Honeywell Plc. We would like to introduce ourselves as one of the leading Manufacturers & Exporters of Pc Control Panel which is actually a DCS PLC Control Panel. Our DCS PLC Control Panel are highly functional and have all the capabilities to perform each and every assigned task with complete wiring & testing as per customer’s satisfaction. Constructed with advanced technical systems, Instrument Control Panels are highly reliable and have all the desired functions which must be present in every process control panel.

...more

Distillery Automation System

Our Distillery Automation System is the most cost effective system amongst the many other distillery system providers. It is integrated with novel techniques and has quality features which are truly reliable. We are one of the most renowned distillery Automation system Provider and suppliers in India who always strives to achieve their customer satisfaction. Salient Features: - Improves Product quality. Regular quantity of product even under varying condition. Eliminates production problems. Control & maintain uniformity. Reduces the production losses.

...more

Digital Panel Meter cum controllers

Micro Instruments is one of the renowned Digital Meters and all types of PID Controllers Suppliers from India. Our digital panel meters and controllers strictly measures and controls the true variation in process. Our digital panel meter and controllers is 100% safe and easy to handle. You will be pleased to know that we offer digital panel process indicator cum controllers at the most rock bottom price. Some salient features of our electric products are: Input-Universal/Specified Display- As required 3½ digit Output-4-20 mA (Optional) Power Supply-230 V AC, 50 Hz

...more

DCS / PLC Control Panel

We would like to introduce ourselves as one of the leading Manufacturers & Exporters of Pc Control Panel which is actually a DCS / PLC Control Panel. Our DCS / PLC Control Panel are highly functional and have all the capabilities to perform each and every assigned task with complete wiring & testing as per customer satisfaction. Constructed with advanced technical systems, Instrument Control Panels are highly reliable and have all the desired functions which must be present in every process control panel.The company is a highly trusted Manufacturer & Exporter of Variable Frequency Drives. The company has recently tied-up with M/S Crompton Greaves as a channel partner for all their electrical products along with Variable Frequency Drives.

...more

Dcs Plc Control Panel 01

We would like to introduce ourselves as one of the leading manufacturers & exporters of pc control panel which is actually a dcs plc control panel. Our dcs plc control panel are highly functional and have all the capabilities to perform each and every assigned task with complete wiring & testing as per customer’s satisfaction. Constructed with advanced technical systems, instrument control panels are highly reliable and have all the desired functions which must be present in every process control panel.

...more

DCS Panel

We would like to introduce ourselves as one of the leading Manufacturers & Exporters of Pc Control Panel which is actually a DCS PLC Control Panel. Our DCS PLC Control Panel are highly functional and have all the capabilities to perform each and every assigned task with complete wiring & testing as per customer�s satisfaction. Constructed with advanced technical systems, Instrument Control Panels are highly reliable and have all the desired functions which must be present in every process control panel.

...more

Centrifugal Automation

This is a known fact that the role of Centrifugal Automation in the process of sugar manufacturing is very vital. As the whole production process depends mainly on the quality of crystal produced by the centrifugal machine, along with that the quantity of sugar produced with respect to the mas-chute is also very important because some how it is directly related to efficiency. As far as our role is concerned we deal in the successful automation of Batch type Old 4/3 speed centrifugal machine. We are already a renowned name in the automation of sugar mill, power plant, refinery and distillery. Centrifugal automation is the branch of sugar mill automation in the boiling house. Technology We increase the efficiency of centrifugal machine by controlling many parameters i.e R.P.M of the motor, timing of particular R.P.M. , timing of plough, pug mill, bottom valve, chute, screen wash etc. As the automation of centrifugal machine in past done mostly by BHARAT BIJLI was based on the electronic card level system which uses very heavy cards along with a lot of power consumption and space. The maintenance of such systems is also difficult because of the use of relay, analog timers, complicated wiring etc. We do the automation of centrifugal machine by using the ML-50 PLC of Honeywell. Special thing about this PLC is that this is lot more reliable, compact, cheaper and efficient than the system used in past. We basically deal in the speed control of 4 speed AC induction motor. Our system operates in auto as well as in manual mode. The operation of our

...more

Boiler Plant Automation

We provides complete turnkey based boiler automation for different industrial uses where this is counted as the most eminent requirement. Our Boiler Plant Automation system is equipped with latest plc/dcs techniques along with perfect selected field sensor and transmitters that provides more prominent results. Amongst the many industrial boiler plants manufacturer from India and other countries, our company proved itself as the major provider of boiler plant automation.Industrial Boiler ControlIntroductionIn the past, boilers in an industrial complex were considered a necessary evil. However today a business manager know this is no longer the case. Boilers are required to maintain maximum steam generation efficiency, maximum reliability, and comply with both stringent air emission and safety regulations. To achieve this goal you need modern control hardware and software. In today competitive market minimization or reduction of operating costs is a valid method to increase profitability. Reducing fuel expenses associated with your boilers can directly impact manufacturing costs. We have a full portfolio of solutions for the industrial power house. DCS/PLC based Boiler control is the most commonly implemented solution. We have developed a control system standard for Bag gas coal-oil- and mixed-fuel-fired boilers, which allows the expertise gained from the implementation of many of the boiler control projects to be made available to our customers.Description The Industrial Boiler Control solution implements the following major control strategies : 3 Element Drum Level control Combustion (Fuel Flow and Air Flow) Control Furnace Pressure Control Single Element Drum Level Control Superheat Temperature Control.

...more

Boiler Automation System

We are presenting highly Advanced Boiler Automation System which has been discovered to add value to the boiling process. Our Boiler Automation System has been designed in a way that it saves energy to a considerable level. We specialize in manufacturing Marine Boiler Automation System that gives desired results in a cost effective manner. The benefits of our Boiler Automation System have been widely acknowledged by the users.

...more

Automation of Centrifugal Machine

This is a known fact that the role of Centrifugal Automation in the process of sugar manufacturing is very vital. As the whole production process depends mainly on the quality of crystal produced by the centrifugal machine, along with that the quantity of sugar produced with respect to the mas-chute is also very important because some how it is directly related to efficiency. As far as our role is concerned we deal in the successful automation of Batch type Old 4/3 speed centrifugal machine. We are already a renowned name in the automation of sugar mill, power plant, refinery and distillery. Centrifugal automation is the branch of sugar mill automation in the boiling house Technology We increase the efficiency of centrifugal machine by controlling many parameters i.e R.P.M of the motor, timing of particular R.P.M. , timing of plough, pug mill, bottom valve, chute, screen wash etc. As the automation of centrifugal machine in past done mostly by BHARAT BIJLI was based on the electronic card level system which uses very heavy cards along with a lot of power consumption and space. The maintenance of such systems is also difficult because of the use of relay, analog timers, complicated wiring etc. We do the automation of centrifugal machine by using the ML-50 PLC of Honeywell. Special thing about this PLC is that this is lot more reliable, compact, cheaper and efficient than the system used in past. We basically deal in the speed control of 4 speed AC induction motor. Our system operates in auto as well as in manual mode.

...more

Auto Cane Feed Control System(Conventional Type)

PLC/DCS based Auto Cane Feed Control System is an star product of MICRO INSTRUMENTS & CONTROL SYSTEM specifically to be used by sugar industries to achieve the targeted performance &smooth Running of the mill by continuous monitoring & maintaining the uniform feed of fiberized cane to the mill and avoid any overloading of the devices in cane preparatory system. This is an most ideal & economical system which allows flexibility of application and over all effeteness Salient features:- a) substantial improvement in crush rate. b) Damage due to choking/jamming at can preparatory device & 1st mill is totally eliminated. c) Fluctuating demand of steam pressure due to irregular feed to the uniform cane feed predetermined rate result in optimum primary extraction. d) By substantial reduction of wear & tear, the down time reduces automatically and thus productivity improves. e) If eliminates the necessary of buffer resistors in cutter motors. Power supply –230 volts A. C. / 50Hz Power Fuse - 1.5 Amps. Digital display – 3 -1/2 digits Level display – LED type. Over load indication –24 - volt Lamp display. Facility: Set RPM and over load by counter dial. Field cable – connected with main unit. Control module – connected with male & female connector. DCS/P.L.C. BASED AUTO CANE FEED CONTROL SYSTEM

...more

Auto Cane Feed Control System

PLC/DCS based Auto Cane Feed Control System-Conventional Type is an star product of MICRO INSTRUMENTS & CONTROL SYSTEM specifically to be used by sugar industries to achieve the targeted performance & smooth Running of the mill by continuous monitoring & maintaining the uniform feed of fibered cane to the mill and avoid any overloading of the devices in cane preparatory system. This is an most ideal & economical system which allows flexibility of application and over all effeteness Salient features : Substantial improvement in crush rate. Damage due to choking/jamming at can preparatory device & 1st mill is totally eliminated. Fluctuating demand of steam pressure due to irregular feed to the uniform cane feed predetermined rate result in optimum primary extraction. By substantial reduction of wear & tear, the down time reduces automatically and thus productivity improves. IIf eliminates the necessary of buffer resistors in cutter motors. Specifications : Power supply : 230 volts A. C. / 50Hz Power Fuse : 1.5 Amps. Digital Display : 3 -1/2 digits Level display : LED type Over load indication : 24 - volt Lamp display. Facility : Set RPM and over load by counter dial. Field cable Connected with main unit. Control module : Connected with male & female connector. DCS/P.L.C. BASED AUTO CANE FEED CONTROL SYSTEM

...moreOpening Hours