Average Customer Rating

Business Rating

Opening Hours

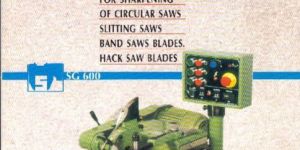

Sandeep Machines Pvt. Ltd, founded in 1923, is a reputable organisation engaged in manufacturing and supplying a wide range of Hydraulic Press, Boring machines, Beam Shaw Machine, Post Forming machines, and Spindle Moulder machines.

Under the supervision of our expertise, the provided array is designed and built in accordance with international quality standards, utilising quality approved components and new technologies in our technologically sophisticated manufacturing centre.

We have created a highly advanced infrastructural base in Ludhiana, Punjab, that spans a large area and is systematically separated into numerous units such as procurement, engineering, manufacturing, quality control, administration, research & development, sales & marketing, and warehouse & packing.

Quality Assurance:

We provide our valued clients with a high-quality range of machines that are created in our well-developed production plant using high-grade ingredients and innovative technologies. At our company, the entire manufacturing process is strictly controlled by our skilled quality analyzers who have an extensive understanding of this field. Our whole product line is evaluated on several quality parameters with the assistance of our quality testing unit in order to eliminate all faults from the selection.

Our Aim:

We have built a dominant position in the market by providing a broad variety of industrial machinery that primarily serves the construction industry. Our objective is to retain consistency in providing clients with the highest quality, reinforced by improved performance, minimalism, and durability.