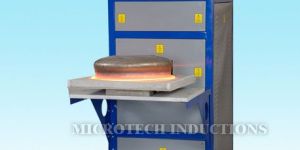

Induction Annealing

Get Price Quote

Annealing is a heat treatment in which material is exposed to an elevated temperature and slowly cooled. Annealing of the material changes physical properties of the material such as strength and hardness.

Microtech induction annealing machines are designed to be used for Normalising, Stress relieving and Process Annealing.

Stainless Steel / Aluminum Utensils

All Cold Formed Steel Components.

Stress Relieving.

Post weld Annealing.

Annealing of Copper tubes.

Annealing of knife, blade ends.

Shell Annealing.

Annealing of wires.

Continuous Annealing of copper wires.

Annealing of brazing wires & Rods.

Annealing of Milk Cans, Oxygen cylinder for neck formation.

Uniform annealing with better quality end product

Lesser Annealing cost comparing to conventional methods

Faster Annealing cycle

Higher productivity

Highest system efficiency

Highly adaptable for automation

Eco-friendly due to noiseless and flameless operation

No statutory approvals required

Lesser risk involved compared to conventional methods

Application Specific

Auto or manual mode operation

Improved power factor

Tropicalised design

Compact size

...more