Wet Mix Macadam Plant

It is of single chassis construction. At each Bin a radial gate is provided which can be opened in any position to regulate the aggregate flow. Individual endless belts are provided, below the gates to discharge material onto the gathering belt.\r\n\r\nA single-deck vibrating screen is provided on the slinger conveyor to remove oversize aggregates received from the 4-bin feeder.\r\n\r\nAn inclined conveyor with 600 mm. wide belt mounted on idlers receives aggregate from the gathering conveyor and feeds it to the pug mill.\r\n\r\nA twin shaft pug mill mounted on antifriction bearing provides quick, continuous and homogeneous mix of aggregates and additives.\r\n\r\nOne / Two Water Tanks of 15 / 20 MT. capacity each are provided, fabricated from steel plates with manhole, flowmeter, pump etc.

Application : ROAD CONSTRUCTION

...more

Road Sweeper Machine

The Road Sweeper is constructed from a pressed steel shell which gives an excellent strength to weight ratio. It is a tractor mounted road sweeper machine driven from the tractor P.T.O. shaft and is available with small debris collector box and water spray equipment as optional. This road sweeping machine is designed for use with almost any tractor which is fitted with hydraulic lift, three point linkage and power take off and can be fitted or detached in less than five minutes.

Material : Metal

...more

Road Roller

‘Speedcrafts’ 3-wheeled Diesel Road Roller, Model DRR/10 (4 speed) & Model DRR-3/10 (3 speed), capacity 8/10 tonnes, generally conforming to IS : 5502 of 1988.\r\n\r\nChassis & Frame\r\nFabricated out of mild structural steel and all joints checked and tested to performance. Easy accessibility to all parts for overhaul and inspection is given utmost importance in design of these Diesel Road Rollers.

Model Number : DRR/10 (4 speed) & DRR-3/10 (3 speed)

Rolling Width : 1810 mm.

...more

Pothole Repairing Machine

The Pothole Repairing Machine is specially used for swift repairing of cracks, potholes, shoulders, fissures, alligator areas and utility cuts. A smaller amount of not more than 1 kg of pressure locates the boom anywhere within a 100 sq. mtr. working area with a vertical assortment of 1525 mm above to 610 mm below concrete level.

Usage : Road Construction

...more

Portable Concrete Plant

These are highly Portable Concrete Plants & is available in 20 cbm/hr capacity. Extremely useful for contractors on the move.\r\n\r\nFeatures\r\n\r\nCompact design\r\nCost Efficient\r\nQuick Installation\r\nLow Maintenance Cost\r\nOne Trailer Load\r\nGlobal Supplies & Support\r\nOptionals\r\n\r\nWheel & Axle for Mobility\r\nCement Silo with Screw Conveyor and Accessories

...more

Paver Finisher

Hoppers have low dump clearance to handle all type of trucks. The wings are raised or lowered hydraulically to give a smaller overall width for transportation and for self-cleaning action during feeding of the asphaltic concrete onto the conveyor.\r\nTwin bar conveyors are provided to feed the material from hopper on to the screws (augers). The conveyors can be independently controlled.\r\nThe asphaltic concrete flows from the main hopper into another hopper containing the augers. These augers are adjustable to cover the full width of the paved surface and each side has independent control.\r\n\r\nInitial compaction of the material is effected through the optional tamper. The tamper is actuated by means of eccentric journals mounted on sturdy roller bearings.\r\n\r\nA heated, fully floating, hydraulically operated and vibrating screed is provided, covering the full length of the paved width. It ensures a predetermined thickness of the asphaltic concrete layer by striking off the excess material. The screed is adjustable for height and camber.\r\n\r\nAll controls are provided within easy reach of the operator from a comfortable driving seat.

Usage/Application : Road Construction

...more

Mobile Hot Mix Plant

‘Speedcrafts’ Bitumen Mixer, Model SBM-10, capacity 6-10 TPH, generally conforming to IS:5890.\r\n\r\nA bucket elevator is provided to discharge aggregate into the drying cylinder through the feeding ring.\r\n\r\nDrying Cylinder discharges heated aggregate into the storage ring. It is supported on two roller tracks running on nos. guide rollers driven by chain and sprocket wheel. Lifting flights are wear resistant and replaceable.\r\n\r\nFitted to the discharge end of the drying cylinder, with a fuel pump for feeding fuel and air blower for supplying air.\r\n\r\nDriven by the engine through a v-belt and is of suitable capacity for the burners provided.\r\n\r\nThe discharge end of the drying cylinder is provided with a storage ring fitted with lifting buckets which discharge the hot aggregate into the batching chute.\r\n\r\nThe batching chute has a fixed volume. Hot aggregate is discharged from chute to paddle mixer by a lever which opens the radial door for discharging the aggregate into the paddle mixer and simultaneously closes a deflector plate at the top of the chute to prevent any material being discharged into the chute while the radial door is open. A thermometer is supplied to register the temperature of the stones in the chute.

Application : ROAD CONSTRUCTION

Capacity : 6-10 TPH

...more

Mobile Concrete Plant

Compact design and fully automatic Mobile Concrete Plant is manufactured upto 15 cbm/hr capacity. Ease of erection and operation is the key feature of this plant.\r\n\r\nFeatures\r\n\r\nCompact design\r\nCost Efficient\r\nLow Maintenance\r\nOne Trailer Load\r\nTop Quality Components\r\nGlobal Supplies & Support

...more

Mobile Asphalt Mixing Plant

The Mobile Asphalt Plant manufactured by our company is technologically uncommon and is available at relatively low cost. The system has high functionality and provides operators with a highly efficient machine allowing for effective and totally satisfying road construction. Also known as Asphalt Hot Mixing Plant, it accommodates operator’s total needs by being easily moved from location to location with relative ease, allowing for speedy assembly and operational use.\r\n\r\nThe dryer is accurately fabricated to ensure proper heating of aggregates with minimum heat loss. It is supported on steel rollers through steel tyreswith idlers and guide rollers and is provided with segmented driving sprocket.\r\n\r\nIt is of single chassis construction. At each bin, a radial gate is provided which can be opened in any position to regulate the aggregate flow. Individual endless belts fitted with variable speed motors discharges material onto the gathering conveyor as per the mix design.\r\n\r\nA fully automatic control panel with feather touch controls is provided for controlling the quantity and quality of production with operator sitting in air conditioned comfort. All systems are completely synchronized with automatic/manual control of burners, load cell, mix temperature, cold feet, mineral, bitumen proportions, etc. Manual control is possible through over-ride system. Adequate safety measures are adopted to avoid overloading, short-circuit, etc.

Type : Asphalt Mixing Plant

...more

Inline Concrete Plant

Plants available in 30 / 45 / 60 cbm/hr capacity.\r\nEquipped with Pan / Planetary / Twin Shaft Mixer.\r\nInline storage of Aggregates.\r\nAggregate weighing conveyor suspended on load cells.\r\nInclined conveyor for feeding of aggregate into mixer.\r\nIndependent weighing system for Cement, Water & Additive.\r\nOperation through Fully Automatic Electronic Control Panel.\r\nManufacturing is done with advanced, internationally recognized techniques at our State of the art facilities.\r\nGlobal presence with prompt after sales support.\r\nDedicated R & D Department.\r\nCement / Fly Ash storage & conveying system up to 100 MT capacity.\r\nRadial Conveyor for feeding of aggregate into the bins.\r\nOutstanding Homogenity In Short Time\r\nLow Wear Design\r\nEasy & Low Maintenance\r\nPLC Based Control\r\nSCADA Interface\r\nAutomatic & Manual Operation\r\nAuto Correction of Water\r\nInventory Control Management\r\nCorrugated Side wall\r\nCleat placement for box formation\r\n40° angle for conveyance of material\r\nRugged structure for long life\r\nCompact Placement of Plant

...more

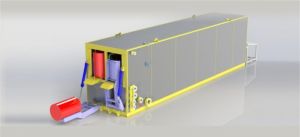

Containerised Concrete Plant

The Containerized Concrete Plant of our company has been designed and developed to cater the production and construction requirements. Easy to carry from one place to another, the machine requires low power to work and discharges the material directly into the transit mixers. The compact design of plant facilitates easy installation in smaller areas. Available in different capacity, which ranges from 36 to 45 cbm/hr, our customers can choose one as per their requirement.\r\n\r\nAdvanced and Compact design from Europe.\r\nEuropean Mixer & Controls.\r\nQuick Installation.\r\nLow Maintenance Cost.\r\nOne Trailer Load.\r\nGlobal Supplies & Support.\r\nWheel & Axle for Mobility.\r\nCement Silo with Screw Conveyor and Accessories.\r\nCement Weigher System on top of Mixer.\r\nDosing system for Liquid Additives.

Type : Containerized Concrete Plant

...more

Concrete Conveyor Machine

The Concrete Conveyor is ideal for operators who require to supply ready mix concrete mixture in 300 degree arc. The conveyor is based on swinging principle and allows pouring of mixture in different directions as per requirement to fill the extended form-works and footings despite of truck being stationery. The conveyor is easy in maintenance and functions with total reliability.

...more

Compact Concrete Plant

Highly compact and fully automatic Concrete Plant is available in 30 m³/hr capacity. Plant could be erected\r\nand dismantled in a day.\r\n\r\n30 m³/hr capacity\r\nCompact design with main unit mounted on single chassis\r\nEquipped with Pan Mixer\r\nSplit bins for storage of aggregate and sand\r\nCement / Fly Ash storage & conveying system\r\nAggregate / Sand weighing & charging conveyor suspended on load cells\r\nIndependent digital weighing system for cement, water and additive\r\nFully automatic control panel\r\nAir conditioned control cabin\r\nManufactured at state of the art facility\r\n24 x 7 Product support

...more

Chip Spreader

Our electric Chip Spreader, based on European design, is installed as a replacement of the rear side board of tipping lorries, by hinges (loose supply) to be welded on the back part of the truck.\r\n\r\nIt is provided with:\r\n \r\nMechanical roller functioning by geared motor connected to the truck battery’s 24 V supply spreading the gravel, with start / stop control taken into the cabin.\r\nChute with spokes, for spreading the gravel.

Application : Road Construction

...more

Bitumen Sprayer

Truck mounted self propelled Bitumen Pressure Distributor with suitable heating system and Bitumen sprayer with variable spray bar to operate on constant pressure system, complete with air-compressor, bitumen pump, auxiliary engine, tank mounting and other accessories for uniform and constant rate applications of hot bitumen (or cold tar) as per the specifications indicated below.

Application : Industrial

...more

Bitumen Decanter

Bitumen drums, with one opened side, are loaded upside down by means of a hydraulic lifting mechanism one by one. The molten bitumen is collected at the bottom of the unit which is equipped with high capacity heating coils. These coils melt the bitumen in a short time and the liquid bitumen is then pumped into the storage tanks through the bitumen pump.

Capacity : 2 x 15 drum/hour x 200 kg/drum

...more

Asphalt Drum Mix Plant

4,000,000 - 10,000,000 Per Per Plant

1 Piece (MOQ)

Our asphalt plants built to stringent International and Indian standards have found acceptance and acclaim by all users. They are thoroughly inspected and tested for quality and reliability by experienced engineers, faithfully uncompromising on quality. The checks begin with the incoming material and components and end only when the finished product is tested and dispatched. We are committed to provide inspired services of the highest achievable standards for absolute satisfaction of our valued customers in terms of sales and service.

Type : Asphalt Plant

Certification : ISO 9001:2008

Application : ROAD CONSTRUCTION

Weight : 35000-50000Kgs

Color : Blue & White Combination

Feature : Durability, High Strength, Long Functional Life, Powerful, Reliable, High Quality

Condition : New

Driven Type : Electric

Warranty : 1yrs

Automation Grade : Automatic, Fully Automatic

Country of Origin : India

...more

Asphalt Batch Mix Plant

15,000,000 - 25,000,000 Per Each Plant

1 Plant (MOQ)

Our Asphalt Batch Mix Plants are being manufactured using Design, Drawing & Technology from a European Company. These plants are available in capacities ranging from 80 tph to 200 tph. Please email us at kushagra@speedcrafts.com or call us at +91 98118 59288 for more information about our Company & Products.

Type : Asphalt Batch Mix Plant

Certification : CE Certified, ISO 9001:2008, ISO 9001:2008 Certified

Application : Mixing Asphalt

Weight : 70000-95000kgs

Color : Combination Of Blue & White

Condition : New

Automatic Grade : Automatic, Fully Automatic

Warranty : 1year

Country of Origin : India

Brand Name : Speedcrafts

After-Sales Service Provided : Internationally Provided

Warranty : 1 Year International

...moreBe first to Rate

Rate ThisOpening Hours