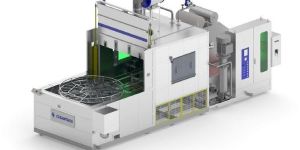

Conveyorised Washing Machine

Request for Price

Introduction

Conveyorized cleaning machine are very useful for high volume production with both general and specific cleaning options. These machines are mostly suitable for medium-sized components.

Description

Conveyorized machines can have either a continuous conveyor or Linear Indexing/stop and go, conveyor.

Components are load at one end and unload from the another end.

These machines are user friendly.

Operations are performed simultaneously.

Linear Indexing/Stop and Go type conveyor is used for precise cleaning.

Application

PUMP HOUSING

COMPRESSOR PARTS

PLASTIC BINS AND TRAYS

SPRINGS

PIPES

PULLEYS

ROTORS

TOOLS & CUTTERS

WIND TURBINE COMPONENTS

AXLE BOX

ROLLER BEARING

CYLINDER HEAD

CYLINDER BLOCKS

CRANKSHAFT

BALANCER SHAFT

CONNECTING ROD

GEARS

CRANK CASE

CRANK COVER

GEAR BOX HOUSING

CAM SHAFT

GEARS AND SHAFTS

AXLE HUB & HOUSING

BRAKE DRUM & HUB

FRONT AXLE BEAM

ALLOY WHEELS

MISCELLANEOUS MACHINE COMPONENTS

Features

SS 304 is used in water contact surfaces.

Excellent operational reliability

Low maintenance cost

24×7 service support

Low running cost

Built in safety

Multi-stage filtration

Cold/ Hot air blow options

HMI panel with indicators

MES/IOT options

Various options for tank heating (like Heat Pump, Gas Heating, Heat Exchanger, Steam , etc.) are available

Number Of Flower : Conveyorized Cleaning Machine

Material : SS 304 On Water Contact Surfaces

Feature : Continuous Or Linear Indexing Conveyor,User Friendly,Simultaneous Operations,Precise Cleaning With Stop And Go Conveyor,Excellent Operational Reliability,Low Maintenance Cost,24x7 Service Support,Low Running Cost,Built-in Safety,Multi-stage Filtration,Col

Applications : Pump Housing,Compressor Parts,Plastic Bins And Trays,Springs,Pipes,Pulleys,Rotors,Tools & Cutters,Wind Turbine Components,Axle Box,Roller Bearing,Cylinder Head,Cylinder Blocks,Crankshaft,Balancer Shaft,Connecting Rod,Gears,Crank Case,Crank Cover,Gear Box

Packaging Type : Industrial Packaging For Safe TransportIndustry Standard Packaging

Storage Type : Store In A Dry, Clean, And Well-ventilated Area

+5

+5

+6

+6

+4

+4

+6

+6

+2

+2

+3

+3

+7

+7

+2

+2