Trim Recycling Machine

Get Price Quote

1 Piece (MOQ)

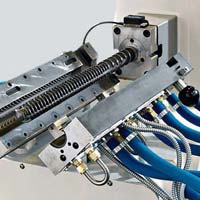

TRIM RECYCLING MACHINE Edge trim unit was introduced on the basis to the subject of “Green Eco Friendly” awareness to the Plastic Film production industry. The unit cleverly integrated advanced structural design with Innovative concept for reclaim trimmed film edge uninterruptedly within the system. The process starting from edge trim feeding, cutting and feeding in the extruder, all in one complete process promised to save labor cost, power consumption and process time.

Plastic Crusher Machine Manufacturers

230,000 - 240,000 Per piece

1 piece (MOQ)

Plastic bottle shredder machine, plastic shredder, shredder machine, bottle shredder machine

Best Deals from Plastic Processing Machinery

Plastic Extruders

1,800,000 Per set

1 Piece(s) (MOQ)

Plastic Processing Machinery

Get Price Quote

Our organization is renowned as reliable distributor in the industry and based in the well-connected state of New Delhi(India). Our reliable and superfast shipping facilities will not let you wait much and will efficiently deliver the range to your doorstep.

PP DANLINE EXTRUSION LINE

4,250,000 Per piece

Plastic Recycling Machine

350,000 Per Piece

1 piece (MOQ)

Plastic Recycling Plant

Get Price Quote

The Plastic Recycling Plant, we offer, is set in accordance with the international standards. It stands high in quality as well as innovation. Its production capacity is ensured to be exactly the same as desired. And its efficiency surfaces from the fact that its results are flawless. We are standing amid the leading Manufacturers, Exporters, and Suppliers of Plastic Recycling Plants from Uttar Pradesh, India. This plant consists of following : Plastic crusher: it crushes plastic containers along with lid. The capacity of the machine is crushing plastics of 40 ton scrap battery in 24 hours. Electricity requirement 40 kW; manpower required one man; machine is water cooled; so, lead dust does not spread around; crushed plastics automatically fed to washing machine. Plastic washing machine: it washes plastic and separate lead dust from crushed plastic. Water is reused and lead dust/ bottom sludge can be collected from this operation. Later it can be sent be to lead furnace for recycling. Plastic rinsing machine: plastic washing machine feeds automatically to this machine with crushed and washed plastic, it rinses in water, and remaining lead dust is separated. Water pumps: two submersible pumps are used in system along with cyclone The whole line is fully automatic and it has characteristics of high efficiency, low noise and easy operation. It adopts hot alkaline water washing to get good quality. Any acid or lead dust is removed by friction washing. Crushed plastic is transferred automatically by inclined material conveyor. Inclined conveyor shifts plastic pallets to rinsing machine. Rinsing machine washes again in clean alkaline water. The pH level is continuously monitored by electrical control panel. Soda ash is charged to washing tank so alkalinity is maintained. This alkaline water neutralizes acidic film formed on the surface of plastic and subsequently clean it. Man power required two men. Lead dust emissions to air is nullified due to its unique design criteria. All emissions are suppressed into water bath so no lead dust is emitted to air. So no particulate matter in the air is created. Lead dust is either transfers with water to E.T.P. Plant or settles down after de-sulphating. Battery container of 40 ton battery/ day.

Plastic Tap Shower

47 Per Piece

10000 Piece (MOQ)

Plastic Stool Mould

500,000 - 900,000 Per piece

1 Piece (MOQ)

Sigma 150T Plastic Hand Molding Machine

1,550,000 Per Piece

1 Piece (MOQ)

Horizontal Plastic Injection Moulding Machine

1,550,000 - 16,500,000 Per piece

1 Piece (MOQ)

Plc Contyroled Automatic Plastic Injection Moulding Machine is Designed for Continues Operation Having Production Rang from 50 Grm/100 Ton to 3.0 Kg 650 Ton Moulding Capacity. Machine is Capable Od Moulding Materialsuch as Nylone Thrmoplastic, Thermo Polymers, Polyurethane, Acrylic Polycarbonate Etc.

Plastic Recycling Machinery

1,550,000 - 1,750,000 Per piece

1 piece (MOQ)

Cling Film Wrapping Sealer

9,250 Per Piece

Single Screw Reciprocating Extruder (PCS 30)

1,675,000 Per set

1 set (MOQ)

Being an extraordinary figure in the industry, we offer a broad range of Single Screw Reciprocating Extruder (PCS 30) to our customers. This versatile and compact small scale extruder is used for customers sampling, research and development and color shade matching. Its scale up capabilities offer top notch efficiency and flexibility. It is easy to use, economical and user-friendly. At reasonable rates, we provide it in safe packaging. Details The Clarion make laboratory Kneader PCS 30 is a versatile, compact small scale compounding extruder for research and development, color / shade matching and customer sampling. This easy,economical, user-friendly laboratory kneader offers similar process characteristics as production scale PCS series machines. Samples from 300gms up to 40 kg/h. Based on its process scale-up capabilities it qualifies as a universal laboratory compounder offering a high grade of efficiency and flexibility. Standard Features and Advantages : Representative data from laboratory samples Throughput rates up to 20 - 40 kg/h Standard Split barrel design for easy access and cleaning, easy maintenance Fine temperature control with independent heating Cooling Zones Standard segmented screw, Liners for easy replacement of wear parts Variable screw speed to match desired properties Optional - Feed Screw with hopper can be installed for small batches Optional – Cooling Roller with belt for the small batch production. Detailed List of Basic Components Inlet hopper Complete barrel assembly with Screw Elements & Liners set fitted on barrel Discharge die with cooled chute Gearbox with Motor drive Main Drive Motor Operator panel with all standard accessories Volumetric Feeder Assembly (Optional) Chill Rolls (Optional) Base Table with Heat Cool Unit Leveling Screws

EPS Cup Making Machine

Get Price Quote

EPS Cup Making Machine, a high-end cup making machine aims to take productivity of a unit to a next level. Developed with revolutionary technology, EPS Cup Making Machine uses efficient working principle for rendering best services. Our EPS Cup Making Machine is greatly demanded for its remarkable workability and longer service life. Application : EPS Cup Making Machine facilitate EPS raw material to expand to the required density Features : Strong M.S. structure S.S. shell 5-Hp. Motor with reduction Gearbox 2- Hp. Motor with High flow Blower EPS raw material Feeding screw device with 1-Hp. Motor & Hopper Parameter control : All manual operation Material Expander Material Expanded Jar Size : Φ 800 *H1200 (mm) Steam Pressure : 0.3-0.6MPA Air Pressure : 0.3-0.6MPA Foaming Ratio : 20~50 Foaming Error (Grain) : �10% Output : 50-160KGS/H Power Consumption : 3KW/H External Power Supply : 3-phase 380V 50Hz Machine Size : 1400mm*800mm*2500mm Machine Weight Approx. : 1.2T Dryer Output of Air-drying :150-200KGS/H Power : 6.6KW Machine Size : 4000mm*800mm*1000mm Central Feeding System Blower Power : 3 sets, 2.2KW Bigger Hopper : 2 pcs,3000mm*3000mm*3000mm Small Hopper : 2 pcs,800mm*800mm*500mm

Cast Silage Film Making Machine

Get Price Quote

1 Piece (MOQ)

A Cast Silage Film Making Machine is a specialized equipment designed to produce high-quality plastic films specifically used for silage wrapping. These films are crucial in modern agriculture for preserving the nutritional value of silage, a type of animal feed made from green forage crops. Key Features of Silage Films Produced by These Machines: High Tensile Strength: Ensures durability and resistance to tearing. Excellent Puncture Resistance: Protects the silage from damage during handling and storage. UV Resistance: Prevents degradation from sunlight. Low Oxygen Permeability: Minimizes oxygen exposure to the silage, preserving its quality. High Moisture Vapor Transmission Rate (MVTR): Allows for effective moisture removal, reducing the risk of spoilage. Features Improved Feed Quality: Protects silage from spoilage, maintaining its nutritional value. Reduced Feed Losses: Minimizes losses due to spoilage, mold, and leaching. Increased Farm Efficiency: Simplifies the silage storage process. Enhanced Animal Performance: High-quality silage leads to better animal health and productivity.

Plastic Injection Molding Machines

Get Price Quote

1 piece (MOQ)

Plastic Injection Molding Machine

Get Price Quote

Plastic Crushing Machine

85,000 - 300,000 Per Piece

1 Piece (MOQ)

SKE-EP Glass Edge Grinding Polishing Machine

196,000 Per Piece

1 Piece (MOQ)

SKE-EP(2HP)SHAPE GLASS HAND EDGE PROCESSING HPRIZONTAL(8X4 FT) BALL ROLLERS TYPE MACHINE ,3 WHEELS ON A SPECIAL SINGLE MOTOR SHAFT FOR 1-6/8 FITS ALL SHAPES GLASS EDGE GRINDING,HALF /FULL ROUNGING WITH CHANGING WHEELS AS PER THK.& PROCESS. SKE-EP(2HP)straight Line and Shapes Glass Hand Grinding , C- Polishing with Changing Wheels Size and Process Wise .machine with Rollers On Plate and Scrolling Special Rolles Strips with Rubber Ball 8x4 Fits Horizontal Heavy Duty 50x50 Mm Square Pipes Structure.2 Hp S/p or 3/ph Special Motor with 3 Wheels On the Same Shaft to Up and Down When Using Rough,Fine & Polish Wheel with Out Changing.with Water Collecting Tray,Tank Pump Electrical Penal Board are Atteche with Machine. Machines are Available in Different Sizes Smaller and Biger as per Your Requirements On Order. Additional Information: Production Capacity: 700 /1000 R.FIT PER DAY Delivery Time: 30 DAYS Packaging Details: WOODEN/PLASTIC AND JUTE