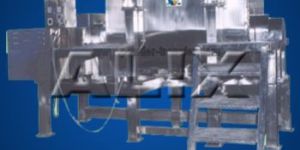

Automatic Bag Cutting Emptying Machine

20,000 - 35,000 / Unit

1 Unit (MOQ)

A Fully Automatic Sack Emptying Station is designed for dust-free, high-capacity unloading of powder and granular materials from 25–50 kg sacks without manual intervention. It ensures consistent throughput, worker safety, and compliance with hygiene standards, making it ideal for pharmaceutical, chemical, food, and plastic processing industries.

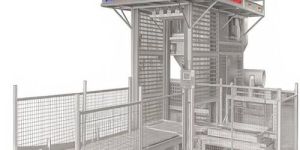

In Automatic Bag Emptying system operates the roller conveyor line, the entire stack will be automatically conveyed into the catching position of bag slitter, the catching device of the bag slitter will come down to grab the whole layer bags layer by layer, and raise up to the set position, then move inside the machine, during this process the cutter blade will cut open the bags from the bottom, material emptying device to empty the material inside the bag, the material by gravity fall into the hopper, empty bag into the waste bag compactor, which collect, compact and extrude out the waste bag. When the whole stack bag is unpacked, the roller conveyor line will automatically transport the empty pallet to the pallet collector to complete automatic collection and stacking of the empty pallet.

Working Process:-

Sack Loading – Bags are placed on an infeed conveyor manually or via a pallet loader.

Automatic Bag Cutting – Rotary or guillotine blades cut open the sack in a controlled enclosed chamber.

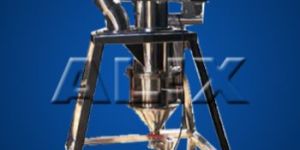

Material Discharge – Contents fall into the receiving hopper, equipped with vibration or screw feeding for continuous downstream conveying.

Empty Bag Separation – Automatic removal of empty sacks via a discharge conveyor into a compactor or waste bin.

Dust Control – Integrated dust extraction ports ensure clean and safe operation.

Continuous Feeding – Material is directly fed into the process line via pneumatic, screw, or belt conveying.

Working Principle:-

Capacity: Up to 20–30 sacks/min (varies with bag size & product type)

Bag Size Range: 25–50 kg standard

Automatic Blade Cleaning System to prevent clogging

Stainless Steel Construction (SS304 / SS316L) for GMP environments

Enclosed Dust-Tight Design with HEPA filtration option

Integrated Empty Sack Compactor

PLC-based Control Panel with HMI touchscreen interface

Safety Interlocks & Emergency Stops

Low Maintenance, Long Service Life

Advantages:-

Sanitary design, mirror polished inside the feeding bin body, with excessive rounded corners and no cleaning dead corners.

Breaking and feeding are carried out in a closed, slightly negative pressure chamber to avoid dust spillage.

Automatic feeding, bag breaking, shaking, and waste bag collection to reduce labor intensity.

Optional WIP on-site cleaning, combined with a dual-purpose water and gas gun for easy cleaning.

Equipped with a touch screen and PLC automation control system, it can be used as a standalone or connected device.

Technical characteristic :-

High integration

The equipment integrates the functions of automatic stack feeding, bag catching, bag emptying, pallets collection and collection & compaction of empty bags.

Intelligent control

PLC built-in program, one click-start, unpacking speed adjustable, automatic fault alarm.

High emptying rate

Above 99.9% – 99.98% high emptying rate, close to 0. material left in empty bag.

Easy maintenance

The equipment is equipped with access doors to facilitate the maintenance of various components outside the equipment.

No bag debris

Through special design, less bag debris generated during the cutting process, equipped with dust filter box, almost 0 dust into the material

Bag size :

Width measured at seam: (W) 400mm (min) – 500mm (max)

Length: (L) 600mm (min) – 1000mm (max)

Thickness: (T) 100mm (min) – 180mm (max)

Weight: 15-25kg (Dimensional dependent)

Construction: Pillow style

Material: Polyethylene or similar

Thickness: 75-120µm (Nominal)

Brand Name : pneuCONVEYOR

Material : Stainless Steel 316L / 304L / Mild Steel,Stainless Steel / Mild Steel

Driven Type : Pneumatic, Elecric

Condition : New

Rated Power : 1-3kw, 3-5kw, 5-7kw, 7-9kw, 9-12kw

Automatic Grade : Automatic

Certification : EIC

Type : Fully Automatic

Country of Origin : India

+5

+5

+6

+6

+5

+5

+5

+5

+5

+5

+3

+3

+5

+5

+1

+1

+5

+5