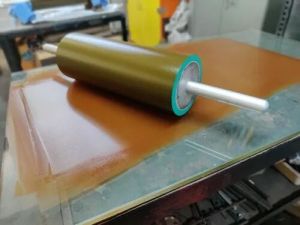

Rubber Roller

Get Price Quote

Roller are basic and primary accessory for web process control in printing industries. Even surface, appropriate material of coating according to the application, uniform hardness over the surface along with precision workmanship play vital roll in performance of the rubber roller. Selection of roller type and coating material depend upon the application & the web material.

A Rubber Roller is an elastic material covering a core usually made of steel, Aluminum or any other material. it has a wide range of application such as the printing and packaging Industry.

Rubber Rollers are used in Plastic Industry, Printing Industry, Paper Industry, Packaging Industry,Textile Industry, plywood Industry, Steel Industry and in many 6ther rubber industry.

Material Of Coatings

Silicon Rubber

Chlorosulphonate Rubber(Hypalon)

Butyl Rubber

Epdm Rubber

Poly Chloroprene Rubber(Neoprene)

Nitril Rubber

Polyurathane Rubber

Teflon Sleeved / Sprayed

Hard Chrome Platted

Applications

Gravure Printing

Flexo Graphic Printing

Furnishing

Esa Printing(electro Statically Assisted Printing)

Solventless Lamination

Adhesive Coating

Film/foil Processing

Steel Pickling

Types Of Rollers

Printing / Impression Furnishing Rollers

Lamination Rollers (Extrusion Lamination, Solvent less / Solvent Base Lamination)

Film Plant Rollers (Nip Rollers, Drum Rollers, Transport Rollers)

Teflon Sleeved Rubber Rollers

Diamond Grooved Rollers

Special Features

Max. Diameter up to 650 mm

Max. Length up to 8000 mm

Uniform hardness all over the surface within + / - 1 shore “A” variation

Wide range of coating to counter chemical / solvent effect.

Outstanding rubber surfacfinish without porosity

...more