V-WELD, backed by the experience and self development with passion for design and development of welding automation systems, today, V-WELD is a respected name in Heavy Engineering Industry and considered a quality original machine manufacturer (OEM), where customer needs reliable and quality products with no short cuts in design, sturdiness, workmanship and manufacturing practice of machines.

V-WELD has started its journey as welding automation designer & integrator & supplied number of welding automation system & integrated various welding process heads of Lincoln, ESAB, MILLER, ADVANI for TIG, MIG, SAW, PAW and other welding applications. V-WELD has successfully developed , supplied & integrated number of weld automation system including Welding Rotators, Welding Positioners, Welding column & Boom (Manipulators), Hard facing solutions, Wire Feeders, Weld Oscillators, Seam Tracking Devices, Arc Voltage controller, weld data logging system, Flux feeding & Recovery systems, Plasma Spraying, Cutting solutions etc.

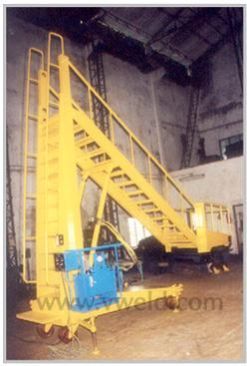

Infrasture: V-Weld has state of art manufacturing and fabrication shop facility, with total covered industrial floor of 35000 sq. ft. It also has uncovered industrial floor of more than 60,000 sq. ft. It has more than 5 motorized EOT cranes to handle various jobs and in house handling facility.

Large list of machineries like Boring machines, Plano-miller, VTL, Lathes, Wire cut machines, etc for doing our jobs. We also have cutting, Welding machines, 300T press, 100T Press, Goliath Cranes & full fledged workshop with all EOT cranes.

Our plant, also has ample concrete floor space for trucking, loading, unloading & storage space & handling etc.

Design: V-WELDis recognized as a quality original equipment manufacturers ( OEM), backed by proven & self developed technology and systems. More than thousands machines and systems are working in India with majority are repeate order, entrusting our quality & reliability.

Read More »