Vertical Plastic Mixer

Get Price Quote

1 Piece(s) (MOQ)

EPS THERMOCOL SHAPE MOULDING MACHINE

1,015,000 - 1,100,000 Per Piece

2 Piece (MOQ)

Product Description Our organization is widely acknowledged in this domain as the leading firm of EPS Shape Moulding Machine. Features: Robust design Easy maintenance High functionality

Best Deals from Plastic Processing Machinery

Plastic Waste Recycling Machine

Get Price Quote

Specifications PE/PP film recycling PE/PP bottle recycling PET bottle recycling Other plastic The main components of the machine Crusher Hot washing machine (can be chased according the customer’s request) Washing machine Drying system

SKE-EP Glass Edge Grinding Polishing Machine

196,000 Per Piece

1 Piece (MOQ)

SKE-EP(2HP)SHAPE GLASS HAND EDGE PROCESSING HPRIZONTAL(8X4 FT) BALL ROLLERS TYPE MACHINE ,3 WHEELS ON A SPECIAL SINGLE MOTOR SHAFT FOR 1-6/8 FITS ALL SHAPES GLASS EDGE GRINDING,HALF /FULL ROUNGING WITH CHANGING WHEELS AS PER THK.& PROCESS. SKE-EP(2HP)straight Line and Shapes Glass Hand Grinding , C- Polishing with Changing Wheels Size and Process Wise .machine with Rollers On Plate and Scrolling Special Rolles Strips with Rubber Ball 8x4 Fits Horizontal Heavy Duty 50x50 Mm Square Pipes Structure.2 Hp S/p or 3/ph Special Motor with 3 Wheels On the Same Shaft to Up and Down When Using Rough,Fine & Polish Wheel with Out Changing.with Water Collecting Tray,Tank Pump Electrical Penal Board are Atteche with Machine. Machines are Available in Different Sizes Smaller and Biger as per Your Requirements On Order. Additional Information: Production Capacity: 700 /1000 R.FIT PER DAY Delivery Time: 30 DAYS Packaging Details: WOODEN/PLASTIC AND JUTE

Automatic Plastic Injection Moulding Machine

1,850,000 - 2,000,000 Per piece

1 Piece (MOQ)

Plc Contyroled Automatic Plastic Injection Moulding Machine is Designed for Continues Operation Having Production Rang from 50 Grm/100 Ton to 3.0 Kg 650 Ton Moulding Capacity. Machine is Capable Od Moulding Materialsuch as Nylone Thrmoplastic, Thermo Polymers, Polyurethane, Acrylic Polycarbonate Etc.

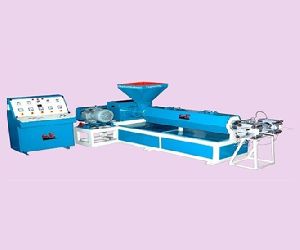

Plastic Extrusion Machines

1,300,000 Per Units

PP Danline Extrusion Machine

3,270,000 Per Piece

1 Piece (MOQ)

Good day sir I’m HIREN DAVE From Shreeji Plastomech Pvt Ltd. Bhavnagar, Gujarat, INDIA. We are manufacturing all types of Plastic Extrusion plants and Rope Making Machines. PP MACRO FABRIC FILAMENT PLANT NYLON MONOFILAMENT EXTRUSION LINE PET MONOFILAMENT EXTRUSION LINE PET WIRE/ PET ZIPPER YARN EXTRUSION PLANT PP/HDPE MONOFILAMENT EXTRUSION LINE TAPE EXTRUSION LINE BALAR TWINE PROJECT EXTRUSION LINE DANLINE EXTRUSION LINE CRUSHING DANLINE CONCRETE FIBER YARN EXTRUSION PLANT INFLOW TWISTER OUTFLOW TWISTER ROPE TWISTER 2-42 MM PLASTIC ROPE MAKING MACHINES COILING MACHINE BOBBIN WINDER COPS WINDER CHEESE CONE WINDER

Automatic Thermoforming Machine Heater

1,200 Per Piece

10 Piece (MOQ)

The Automatic Thermoforming Machine Heater is a powerful 220V electric heater made of durable stainless steel. Specifically designed for thermoforming machines, it boasts a temperature range of up to 500°C and a wattage of 1000W, ensuring efficient and precise heating for your thermoforming processes.

Plastic Extruders

1,800,000 Per set

1 Piece(s) (MOQ)

Plastic Mixture Machine

1,250,000 Per Piece

1 piece (MOQ)

Mild Steel Extrusion Dummy Block

70,000 Per piece

2 piece (MOQ)

Horizontal Screw Type Plastic Injection Moulding Machine

850,000 Per

1 piece (MOQ)

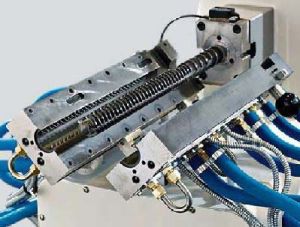

Single Screw Reciprocating Extruder (PCS 46)

225,000 Per set

1 set (MOQ)

Relying on our know-how in the industry gained over years, we, as a Manufacturer and Supplier of Single Screw Reciprocating Extruder (PCS 46) have put us in the top band of the industry. It can be easily cleaned in a short time span. Our customers can also save their costs as it consumes less heat and power. It also takes lesser time and energy in case of a power failure. Advantages No need of additional lab extruder for product development, shade / color matching, RM testing Easy & fast cleaning due to short length, easy & fast cooling due to water heating system Wide range of products can be produced on single screw extruder - like PU, PTFE, low curing, etc. Running cost is low as compared with Twin Screw - Low Power, Low heating cost Small batches can be easily possible Thorough cleaning is possible in small time span. Consistence product Quality possible due precise Temp Control, no problem of jamming, no problem of product deletion Low maintenance cost as compared with Twin Screw Modular design of Screw Elements to felicitate the change in kneading / feeding lengths Thru Cooling Shaft - ensures the controlled process temp. / easy cleaning of screw & avoiding deletion in the barrel. process length is much less than the Twin Screw extruder, ensures less residence time for product. machine is easy to operate If power failure occurs - takes less time / less energy for restart Due close loop heating cooling system - load on chilling gets reduced drastically Disadvantages Fine processing is limited to certain extent ( in case of rejection processing) requires extra care to be taken Spares cost is high ( but / kg cost is low as compared with twin) Thorough Cleaning is time consuming / you may need to keep spare set of Screw Shaft

Manual Plastic Molding Machine

50,000 Per Piece

HDPE Plastic Drum Blow Molding Machine

650,000 Per

1 Piece (MOQ)

Plastic to Oil Plant

Get Price Quote

Plastic Waste is treated to produce Low Density Oil (LDO), Carbon and Liquified Petroleum Gas (LPG). LDO can be further refined to a better quality fuel like Petrol & Diesel.

Sigma 150T Plastic Hand Molding Machine

1,550,000 Per Piece

1 Piece (MOQ)

Single Screw Extruder

160,000 - 1,250,000 Per Piece

1 Unit (MOQ)

Plastic Storage Mixer

Get Price Quote

1 Piece (MOQ)

Plastic Crushing Machine

Get Price Quote

The shaved lid which is separated from under the welded straps is sent through conveyor to Lid Crusher Machine. Plastic parts are separated from the Lead parts. Such plastic parts are sent to the Plastic Crusher & are cut into smaller pieces. This machine is used to crush Battery Container made of Plastic Material. It crushes to small Pieces up to size of 1" square in one go and Washes Lead accumulated on it. It is shearing & hammering action increases its Power versus Output Ratio. Lead is precipitate on another conveyor. This conveyor conveys Lead Particles Pieces to one side. Plastic which can float on water will be filtered on another Conveyor. Plastic is fed to Plastic Washing Machine. This Plastic Washing Machine washes Plastic with Soap Solution. Plastic is filtered and collected. Water is used again after purification.