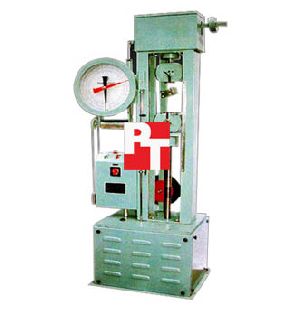

Briquette Testing Machine

Get Price Quote

1 Set(s) (MOQ)

We are offering briquette testing machine. The instrument employs a friction free, accurate, double lever system, the load being applied by means of sliding weight on the top lever. The capacity of the unit is 900 kgs.

Hydraulic Briquetting Machine

1,200,000 Per Piece

1 Piece (MOQ)

Best Deals from Briquetting Machine

Sawdust Making Machine

325,000 - 450,000 Per piece

1 Piece (MOQ)

Briquette Press

Get Price Quote

We offer a wide range of Briquetting Press Machine. High-density fuel naming Bio Mass Briquette is manufactured from all type of binderies, degraded residues such as sawdust, bagasse, cotton stalk, coffee husk, pine needle, ground nut shell, which is a total waste and is a big problem for us which can be used in this briquette press.

Horizontal Metal Briquetting Machine

1,000,000 Per Piece

Press Briquette Machine

Get Price Quote

5 Piece (MOQ)

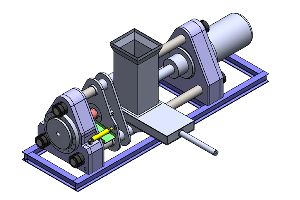

Vertical Briquetting Machine

Get Price Quote

Briquetting Machine is one of the technology used in scrap processing . The metal chip, or metal dust need to reuse and this machine can make the small meta chip into briquettes. People can name the briquettes as Tikki or Cake or Biscuit format then it is used to smelting. Cast iron dust becomes cast iron again; iron included in further dusts is reduced and converted to metal. The Briquetting machine manufactured by Advance hydrautech is available horizontal form and in Vertical form. Our manufactured Briquetting Machines are widely known for quality and performance.

Briquette Testing Machine

Get Price Quote

General Description & Specification: 0-500 Kg. Complete with one briquette mould and set of weights to weigh 50, 100, 150 and 200 kg. without lead shot. Optional Accessories: 0-900 Kg. The instrument employs of friction free, accurate, double, lever system, the load being applied by means sliding weight on the top lever The capacity of the unit is 900 kgs. After fixing the briquette in the jaws, the machine is swithched on. The sliding weights slides over the calibrated lever thus applying tension to the specimen A micron-Switch fitted instantly stops the machine on failure of the briquette and on failure the tensile load is accurately read to 0.5 Kg by means of a marker provided on the sliding weight. The machine can be made operationable for subsequent test only after bringing the sliding the weight to its zero position. Suitable for operation on 230 volts, 50 cycles, single phase A.C. supply. Complete with one brass briquette mould and one base plate.

Briquetting Press 3 Dia Machine

Get Price Quote

Advance Hydrautech Pvt Ltd. is the leading manufacturer and exporter of Briquetting Press 3” Dia in India. Our manufactured Briquetting Press 3” Dia are widely demanded in the market for their high performance and low maintenance. We are India’s largest Manufacturer of Briquetting Press for Metal Dust. Our offered Briquetting Press 3” Dia is fabricated under the guidance of ingenious professionals using premium quality components and ultra-modern technology in tandem with set market standards.

Vertical Briquetting Press

Get Price Quote

Advance Hydrautech Pvt Ltd. is the leading manufacturer and exporter of vertical briquetting Press in India. This metal chip briquetter is very useful for producing good quality metal briquettes. This machine is useful for any type of metal chips. Our manufactured Vertical briquetting Press are widely demanded in the market for their high performance and low maintenance. Our offered briquetting Press is fabricated under the guidance of ingenious professionals using premium quality components and ultra-modern technology in tandem with set market standards.

Briquette Press

Get Price Quote

Our briquetting machines can produce briquettes which have been compressed at a ratio of up to 1:25. These briquettes can be smelted with almost no losses. The machines can also press out any oils or emulsions which may be adhering to machining chips. The compression of scrap to the extent of 5000 kgsq cm ensures that almost every possible metal & waste gets briquetted without molasses or any other adhesive. Such considerable reductions in the volume of wastes lead to significant savings in the haulage and storage costs and minimise the losses incurred during smelting. Due to the great value of the reclaimed material, many companies see a pay back on their capital investment in 3 to 12 months.

Briquette Press Machine

Get Price Quote

1 750 kg/hr (MOQ)

TENSILE BRIQUETTE TESTING MACHINE

Get Price Quote

0-900 Kg. The instrument employs of friction free, accurate, double, lever system, the load being applied by means sliding weight on the top lever the capacity of the unit is 900 kgs. After fixing the briquette in the jaws, the machine is switched on. The sliding weights slides over the calibrated lever thus applying tension to the specimen. A micron-Switch fitted instantly stops the machine on failure of the briquette and on failure the tensile load is accurately read to 0.5 Kg by means of a marker provided on the sliding weight. The machine can be made operation able for subsequent test only after bringing the sliding the weight to its zero position. Suitable for operation on 230 volts, 50 cycles, single phase, A.C. supply. Complete with one brass briquette mould and one base plate

Briquette machine

Get Price Quote

We offer fully integrated and automated Briquette Plants & Products. Highlights of our technology are. Lower electricity consumption. Ability to run round the clock. Lower Downtime. Low cost of wear parts and consumables. Dust Free operations. Flexibility to suit all Raw Materials. Minimum manpower requirement.

Briquette Press Machine

450,000 Per Ton

Briquetting Machine

Get Price Quote

1 Piece (MOQ)

lehra machine

Get Price Quote

The new & improved Nagam has an ABS plastic body fitted with a SMPS, universal power supply from 90V AC to 250V AC. This electronic laya making instrument is capable of producing a staggering 194 tunes in 20 taals. It comes in with as independent Nagam volume, drone & metronome control. For better tabla practice sessions there is riyaz time indicator & metronome at odd lays too. It has 7 tone combinations with 2 different playing styles. Its inbuilt composer is capable holding 4 tunes at 95 mantras each. Running on 8 (AA cells) batteries, along with its inbuilt battery charger operations this is the best electronic lehera machine in the world.

Hydraulic Metal Briqueting Machine

Get Price Quote

Briquette's are used in the process of recycling for steel turnings, cost iron barings, copper or brass powder, etc. Turning specifically ore too bulky to fill o melting furnace efficiently. Normal baling is no solution because of their great elasticity— the bole would fall apart, as with paper gecko' textiles.Before turnings can be briquetted they must be chopped, shredded or broken when they become dense (in the form of unbroken swarf). This process involves double treatment in which very high pressure is exerted on a small area, a relatively expensive processing method. The standard sizes of briquette is 12 to 15 cms (diameter) & 10 ems (length). Increase your bottom-line profitability when you turn to santec hydraulic briquette machine . You con transform your industrial turnings, filings, chips, clippings and even metallic dust from copper, brass, aluminum and other metals into economical, compact briquettes that are worth more than non-compacted soap metal. In addition to improved profitability and 'educed waste, hydraulic briquettes can also: Minimize hazardous liability exposure and recover more culling fluids. A briquette machine squeezes out harmful coolants from metal shavings, creating briquettes that typically hold less than NO percent moisture. Lower transportation and material-handling costs. With o volume-reduction rote of up to 8:1 (rote dependent upon metal type), you can recycle greater amounts of scrap per load with easy-to-ship briquettes. Increase available floor space. You con convert scrap-storage space into revenue-producing manufacturing areas. Every manufacturers goal!

biomass briquetting plant

Get Price Quote

Corporate farming, Heat Pipe, Radhe Green Agri Tech

Briquetting Machine

Get Price Quote

Briquetting Machine, Baling Press Machine, Shredding Machine

Biomass Briquette Machine

Get Price Quote

Biomass Briquette Machine, Crane Load Moment Indicator

Automatic Briquetting Press

Get Price Quote

Automatic Briquetting Press