wire wound finned tubes

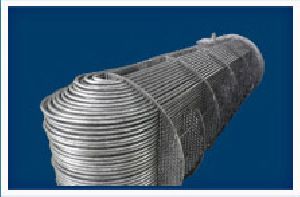

wire wound fin tubes

The method of attaching the fins over tube is of prime importance, since even a slightest air gap between the tube and fins will defeat the whole purpose of fins over the tube.Considering the above facts Heft has indigenously designed and developed a special purpose tube fining machine capable of producing following types of finned tubes.WOUND FINNED HEAT EXCHANGERS tubing used in the maintenance and manufacture of the air cooled heat exchangers, air heaters & other related heat exchangers.

...more

tube finning machine

The method of attaching the fins over tube is of prime importance, since even a slightest air gap between the tube and fins will defeat the whole purpose of fins over the tube. Considering the above facts Heft has indigenously designed and developed a special purpose tube fining machine capable of producing following types of finned tubes. HEFT was formed in 1994 to provide the service to petrochemicals, power generation, chemicals, pharmaceuticals industries with high quality HELICAL WOUND FINNED HEAT EXCHANGERS tubing used in the maintenance and manufacture of the air cooled heat exchangers, air heaters & other related heat exchangers.

...more

steam heater

Spiral Wound Finned Tube

Fins are basically external surfaces on tube for increasing the surface area of the bare tube, resulting in a compact Heat Exchanger. The method of attaching the fins over tube is of prime importance, since even a slightest air gap between the tube and fins will defeat the whole purpose of fins over the tube. Considering the above facts Heft has indigenously designed and developed a special purpose tube fining machine capable of producing following types of finned tubes. HEFT was formed in 1994 to provide the service to petrochemicals, power generation, chemicals, pharmaceuticals industries with high quality HELICAL WOUND FINNED HEAT EXCHANGERS tubing used in the maintenance and manufacture of the air cooled heat exchangers, air heaters & other related heat exchangers. Finned tubes are able to even out the heat transfer between the inside of the tube and the outside. When the heat transfer coefficient on the outside of the tube is significantly lower than the heat transfer coefficient on the inside of the tube, there is a major advantage to incorporate fins on the outside tube surface to take full advantage of the high heat transfer rate on the inside of the tube. By using a finned tube with eight times as much surface on the outside of the tube, the total length of the tube required for heating the viscous oil can be reduced by one sixth, Fins are basically external surface on tube for increasing the surface area of the bare tube, resulting in a compact heat exchanger.

...more

Spiral Fin Tubes

Finned tubes are able to even out the heat transfer between the inside of the tube and the outside. When the heat transfer coefficient on the outside of the tube is significantly lower than the heat transfer coefficient on the inside of the tube, there is a major advantage to incorporate fins on the outside tube surface to take full advantage of the high heat transfer rate on the inside of the tube.By using a finned tube with eight times as much surface on the outside of the tube, the total length of the tube required for heating the viscous oil can be reduced by one sixth, Fins are basically external surface on tube for increasing the surface area of the bare tube, resulting in a compact heat exchanger.

...more

Tube Heat Exchangers

We are offering shell & tube heat exchangers we only concentrate on heat exchangers from simple oil coolers to complex shell and tube heat exchangers. Heft can design and manufacture heat exchangers related to almost all industrial application. Design heft, specially developed software carries out calculations related to minor aspects of mechanical and thermal designs of heat exchangers. The software works according to asme & tema standards. Size and types the sizes range from 2" od to a few meters, in a single or multiple pass. tubes can be straight or 'u' bundle. fixed-tube sheet design. full-through floating-head design. split-ring floating-head design. bayonet tube design. Material heat exchangers are fabricated in hastealloy, inconel, all grade of stainless steel & carbon steel & any other weldable material operating in moderately high pressure and temperature range.

...more

Shell & Tube Heat Exchangers

From simple Oil Coolers to complex Shell and Tube Heat Exchangers. Heft can design and manufacture heat exchangers related to almost all industrial application. DesignHeft, specially developed software carries out calculations related to minor aspects of mechanical and thermal designs of heat exchangers. The software works according to ASME & TEMA STANDARDS. Size and Types The sizes range from 2" OD to a few meters, in a single or multiple pass. Tubes can be straight or 'U' bundle. Fixed-Tube Sheet Design. Full-Through Floating-Head Design. Split-Ring Floating-Head Design. Bayonet Tube Design. MaterialHeat Exchangers are fabricated in Hastealloy, Inconel, all grade of Stainless Steel & Carbon Steel & any other weldable material operating in moderately high pressure and temperature range.

...more

Oil Coolers

Technical SpecificationHeat Load: Upto 230 KW. Oil Flow Rate: Upto 375 Lit./Min. Availability: One, Two & Four Pass Material Of ConstructionTubes : Copper / CU-NI / M.S / Stainless Steel Baffels: Brass / M.S. / S.S Shell: IS226 / Brass ApplicationsDiesel EnginesMarinePlastic MachineryHydraulic Power Packs & other Industrial applications

...more

Oil - Coolers

Technical Specification Heat Load : Upto 230 KW. Oil Flow Rate : Upto 375 Lit./Min. Availability : One, Two & Four Pass Material Of Construction Tubes : Copper / CU-NI / M.S / Stainless Steel Baffels : Brass / M.S. / S.S Shell: IS226 / Brass Applications Diesel Engines Marine Plastic Machinery Hydraulic Power Packs & other Industrial applications

...more

Multi Stage Heat Exchangers

Multi Stage Heat Exchangers are specially designed for refrigeration application, features and performance characteristics that make the difference. their compact sizes makes them easy to package and install, saving time and money over Shell & Tube Heat Exchangers.When performance counts, the professionals specify Multi-stage heat exchanger, the standard for compact, high efficiency multi stage heat exchanger technology. Multi stage heat exchangers are available in a variety of sizes for refrigerant application with capacity 1/2 tons to 10 tons. Multi Stage Heat Exchangers are upto 50% smaller than traditional shell & tube heat exchanger. Smaller size means less refrigerant charges for the same performance, this heat exchangers feature high heat coefficients resulting in greater overall performance & also have lower fouling rates, contributing to long life efficiency.

...more

Finned Tubes

We are offering finned tubes. Spiral wound finned tube fins are basically external surfaces on tube for increasing the surface area of the bare tube, resulting in a compact heat exchanger. The method of attaching the fins over tube is of prime importance, since even a slightest air gap between the tube and fins will defeat the whole purpose of fins over the tube. Considering the above facts heft has indigenously designed and developed a special purpose tube fining machine capable of producing following types of finned tubes. Heft was formed in 1994 to provide the service to petrochemicals, power generation, chemicals, pharmaceuticals industries with high quality helical wound finned heat exchangers tubing used in the maintenance and manufacture of the air cooled heat exchangers, air heaters & other related heat exchangers. Finned tubes are able to even out the heat transfer between the inside of the tube and the outside. When the heat transfer coefficient on the outside of the tube is significantly lower than the heat transfer coefficient on the inside of the tube, there is a major advantage to incorporate fins on the outside tube surface to take full advantage of the high heat transfer rate on the inside of the tube. By using a finned tube with eight times as much surface on the outside of the tube, the total length of the tube required for heating the viscous oil can be reduced by one sixth, fins are basically external surface on tube for increasing the surface area of the bare tube, resulting in a compact heat exchanger.

...more

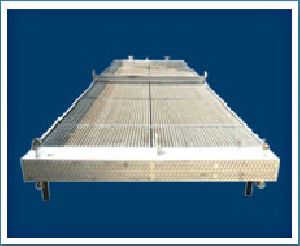

Air Cooled Heat Exchangers

We are offering air cooled heat exchangers heft engineers are specialized in to design and manufacturing of air cooled heat exchanger, using in-house manufactured finned tubes. These heat exchangers offer following advantages over other conventionl & crimped type finned tube heat exchangers. more surface area per square feet of heat exchanger lower air resistance, resulting in less power to deliver the requires c.f.m. reduction in number of tubes for given b.t.u. Transfer per rate area, resulting in fuel saving light weight easier handling more fins per inch can be incorporated on entire tube length the combination of low friction air loses high air velocity and maximum heat transfer per square feet of face area results in extremely high heating or cooling capacity of heat exchanger in a given space. The company has its own fining facilities, where finned tubes with various configuration and in variety of materials are manufactured. Available in 'g', 'l' plain & crimped configuration. The finned tubes can be assembled to performance requirement of your specific application. Typical industrial application where heft air cooled heat exchangers are in operation.

...more

Air Cooled Heat Exchanger

Heft Engineers are specialized in to design and manufacturing of AIR COOLED HEAT EXCHANGER, using in-house manufactured finned tubes. These heat exchangers offer following advantages over other conventionl & crimped type finned tube Heat Exchangers. More surface area per square feet of heat exchanger Lower air resistance, resulting in less power to deliver the requires C.F.M. Reduction in number of tubes for given B.T.U. transfer per rate area, resulting in fuel saving Light weight easier handling More fins per inch can be incorporated on entire tube length The combination of low friction air loses/ high air velocity and maximum heat transfer per square feet of face area results in extremely high heating or cooling capacity of heat exchanger in a given space. The company has its own fining facilities, where finned tubes with various configuration and in variety of materials are manufactured. Available in 'G', 'L' plain & crimped configuration. The finned tubes can be assembled to performance requirement of your specific application. Typical industrial application where HEFT AIR COOLED HEAT EXCHANGERS are in operation.

...more

aircooled heater

crimped

Heat Exchanger

Multi Stage Heat Exchanger

We are offering multistage heat exchangers are specially designed for refrigeration application, features and performance characteristics that make the difference. Their compact sizes makes them easy to package and install, saving time and money over shell & tube heat exchangers. When performance counts, the professionals specify multi-stage heat exchanger, the standard for compact, high efficiency multi stage heat exchanger technology. Multi stage heat exchangers are available in a variety of sizes for refrigerant application with capacity 12 tons to 10 tons. Multi stage heat exchangers are upto 50% smaller than traditional shell & tube heat exchanger. Smaller size means less refrigerant charges for the same performance, this heat exchangers feature high heat coefficients resulting in greater overall performance & also have lower fouling rates, contributing to long life efficiency.

...moreBe first to Rate

Rate ThisOpening Hours