Tubing

Following kinds of tubes are available for single shot lubrication system: 1. Steel Tubes : These are zinc plated MS Seamless tubes with thickness of 0.89mm a. Steel Tube 6mm OD : Tube with 6mm OD is used for Main Line from pump to each junction blocks. It has smallest bending radius of 22mm and permissible pressure more than 200 kg/cm sq. b.Steel Tube 4mm OD : Tube with 4mm OD is used for branch line from metering cartridges to end points. It has smallest bending radius of 8mm and permissible pressure more than 200 kg/ cm sq. 2. Nylon Tubes : These are semi transparent flexible tubes of material Nylon 6. These tubes are easy to work with. These are necessary for the points, which have motion. For better tube life, it can be protected with springs available with us. Thickness of tube in 1mm. a. Nylon Tube 6mm OD : This tube has minimum bending radius of 70 mm and maximum permissible operating pressure 45kg/cm sq. b. Nylon Tube 4mm OD : This tube has minimum bending radius of 50 mm and maximum permissible operating pressure 60kg/cm sq. 3. Hoses : Hoses are used for points where flexibility is a must and also mechanical strength is more such as sharp edges, area with movement of heavy components, chip falling area in machine tools etc. These hoses are made up of synthetic rubber with textile reinforcement. a. Hoses with 6mm OD steel ends : Hoses are supplied with reusable type end fittings, with 6mm OD round ends of 25mm length. This hose has ID of 6.3 mm and has an operating pressure of 28 kg/cm sq. b. Hoses with 4mm OD steel ends : Hoses are supplied with reusable type end fittings, with 4mm OD round ends of 22mm length. This hose has ID of 4.8 mm and has an operating pressure of 35 kg/cm sq.

...more

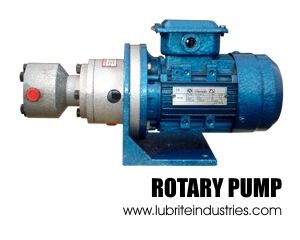

Rotary Pumps

These Pumps with positive displacement of oil are great type and are suitable for different applications such as lubrication of head stocks. Gear Boxes, low pressure hydraulic power packs and recalculating units etc. These pumps are suitable for oil with wide range of viscosity 30-400cst/40 c.

...more

Recirculating Units

COL (Continous Oil Lubrication System) is meant to lubricate bearing of driers in the forny/ back side of paper machine. The COL generally consists of stand by Geared Pumps. Duplex Filters, heat exchanger & necessary instruments such as pressure switch, differential pressure switch, thermometer, pressure gauges etc to monitor the working of the system. Oil is lubricated to the each bearing with the networking of pipe lines & fittings. Inline filters & heat exchanger cleans as well as cool the oil before it enters the bearing housing. The same oil is then ejected from Bearing Housing to the COL tank through return header.

...more

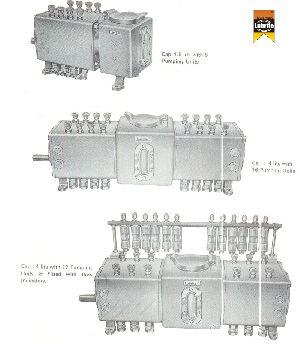

progressive blocks

A Progressive Block with one inlet & number of outlets is a hydraulic valve in block form which divides in going grease in equal metered amount with a help of plunger pins moving to & fro in the controlled holes of the segments. With the input grease pressure, piston pins move to one side in sequenProgressive Blockce ejecting metered amount of grease. When passage is clear from last to first outlet, cycle is repeated. Outlets from Progressive Block must be connected with lubrication points. DO NOT BLOCK ANY OUTLET OF PROGRESSIVE BLOCK. It will stop working in case of choking of any lubrication points. To get the indication, one of the plungers is extended out. When this plunger moves, the indication pin can be visualized which ensures the working of the Block. Electric Sensing can also be monitored by providing Proximity Switch in the block.

...more

Pneumatic Lubricators

These pumps are similar to Hand Pump, except that the Handle is substituted with Pneumatic Cylinder, Air Pressure is fed at the input port of the pump which actuates built in cylinder and thereby piston of the pump. Lubricating oil with fixed quantity & pressure of 15 kg/cm sq. is discharged from the outlet whenever air pressure is maintained 5-7 kg. per sq cm. maintained in the pneumatic line. For recharging of the pump for next impulse, pressure in Pneumatic line must be dropped down to zero. These pumps can be successfully used as Automatic Lubrication System with the help of direction control valve and electronic timer.

...more

pneumatic grease pumps

The Pneumatic Cylinder is buit-in with the Pump and is operated with Pneumatic lines connected to the ports of the cylinder through manual / electrical Direction Control Valve. During the forward stroke, greaseis ejected under pneumatic pressure from the outlet port of the pump body and during the reverse stroke of the cylinder grease is sucked through suction port in to the pump body. These pumps are wall mounted and should be installed in vertical position at a place conveniently accessible to the operator. Bleed Valve is provided on the pump body to bleed air entrapped in the system. Before operating the pump, Bleed Valve is kept open till the continue flow of grease starts from it. A tell tale rod projecting through the container top indicates the remaining grease at any time. To ensure that Pneumatic lines to the pump is dust & moisture free - Provide Filter & Regulator unit in the air lines

...more

Pneumatic Grease Pump

The Pneumatic Cylinder is buit-in with the Pump and is operated with Pneumatic lines connected to the ports of the cylinder through manual electrical Direction Control Valve. During the forward stroke, greaseis ejected under pneumatic pressure from the outlet port of the pump body and during the reverse stroke of the cylinder grease is sucked through suction port in to the pump body.

...more

Penumatic Grease Dispensers

Pneumatic Grease dispensers are used to meet all grease lubrication needs. A wide range of grease dispensers are available of capacity 25kg. & 50 kg. it can be connected directly on the greasing points. also suitable for centralised lubricating grease systems. the anti-air lock pressure plates ensure easy flow of grease. The grease dispensers are provided with trolley for easy movement with little efforts. The Lubrite Pneumatic grease dispensers meets the highest standards in quality. Aluminium alloy pump. power coated/nicked finish external components & highest standard accessories ensures long life and trouble free working of the result

...more

Oil Lubricator

In OIL MIST LUBRICATORS a drop of oil is split by high velocity of airflow 3~5 kgsq.cm with air regulator. Quantity of oil can be adjusted by the help of adjustment screw by rotating clockwise or anti-clockwise. the oil drop indicator is provided at top to check the speed of oil drop visually . The system is capable of running continously. for automation, solenoid valve & timer can be provided as additional feature. Air pressure as well as oil drop setting is very important for efficient working

...more

Oil Flow Meters

OIL FLOW METERS are used to regulators the flow of oil in each lubrications pont. it is the most essential part for COL system as the performance of he complete system depends on the Rotameters. it consists of adjustable Throttle valve. Flow Indicator & Float Assembly. As the flow indicator is made of polycarbonate, the flow rate can be easilly visualized with the movement of the Float. Rotameters are available in diffrent flow range as per requirment. Electric sensing can be provided if required.

...more

Multiline Mechanical Lubricators

Multiline Mechanical Lubricators are used for Automatic Centralised Lubrication System for Industrial, Marine and similar applications where Lubricant to be used is oil over a vide range of visosity from SAE 20 to SAE 250. Driven by plant it serves or using its own electric motor with reduction Gear, Lubrite Multiline Mechanical Lubricators provide precise and continuous Lubrication from a Central location. The special feature of this (Brentford Type) system is its unit construction which by allowing various combination of the components, ensures a Lubrication system matched to any particular requirement. GENERAL DISCRIPTION: The basic unit comprises a reservoir of appropriate capacity and the required number of pump units with rotatable Banjo outlets. Each Multiline Mechanical Lubricators pump unit is fitted with a check valve. Lubricators upto 10 pumping units can be supplied with 750 ml and 1.5 ltrs reservoirs and 8 to 20 pump units with 4 ltrs reservoir. Reservoir capacity is nominal and total capacity includes the pump assembly casting. Oil level is indicated through a sight glass on all the models. PUMP OPERATION: The pump drive shaft is provided with cams, one for each pair of pup units. These operate rocker arm which move pair pistons alternately up and down in their respective cylinders. Each pump unit serves one Lubrication line. The drive Shaft can be rotated in either direction. The amount of Lubricant delivered is adjusted by the knurled knobs on top of pump body. The knobs are provided with check nuts to prevent accidental movement. FLOW INDICATOR ASSEMBLIES: An assembly comprises the Appropriate number of flow Indicators mounted on a suitable Frame. These flow indicators indicate the regularity of delivery and flow in each oil line. Flow indicators are designed to operate oils of viscosity 41 to 173 centistoke at 40 deg C. Heavier oil must not be used. SPECIFICATIONS: Recommended speed:- Between 10 & 100 rpm. Discharge:- Between ) & .1cc. per pumping unit per stroke. Reservoir capacity: 750 ml, 1.5 ltrs, 4 ltrs. Pressure developed: 1000 psi without flow indicators and 500 psi with flow indicators. This Mechanical Lubricator with Two Outlets and Manual Priming Pump Has been specially designed for Centralised Lubrication system to number of points through two outlets. These two Outlets and the outlet of Priming Pump is connected to the oil feed line, branched to number of points with Nylon or Steel Pipe (4 mm O.D.) through junction Blacks. Metered Flow Units are provided on the Lubrication points of the Machine to feed the required quantity of oil. SALIENT FEATURES: Centralized Multiline High pressure Lubricators 1 to 20 Outlets. Each point separately fed for individually adjustable for flow. Visual Indication oil availability at the reservoir and flow to the bearings. Individual adjustment central for flow. Foolproof, elimination of 'missed' and inaccessible bearings. Saving of oil-Economy. Maximum reliability-minimum downtime. Design & installation advisory service. Easy spare parts availability. Guarantee for trouble free performance for 6 months.

...more

motorised lubrication units

Motorised Lubrication units are electric motor driven pumps along with reservoir, oil filter & breather, suction strainer, pressure relief valve & bleed valve etc. The units installed are suitable for Single Shot Automatic Oil Lubrication. These motorised Lubrication Units are to be run intermittently only. During Motors ON time (Normally 5 seconds) all the metering cartridges eject out predetermined amount of oil at various points of the machine. And during motors OFF period (selectable) the metering cartridges get recharged for the the next Lubrication Cycle. If desired, these units can be supplied without float & pressure switch as per customer requirements. Units for liquid grease (fluid grease) are also manufactured.

...more

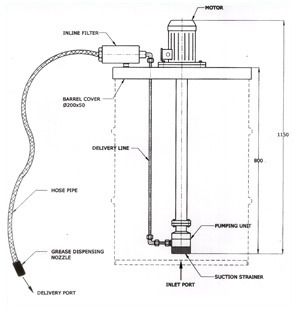

Motorised Grease Transfer Pump

Motorised Grease Transfer Pump LUBRITE grease filling gear pump is designed for transferring grease from a barrel to the reservoir of centralised grease lubricating station. the pump which is mounted at the bottom of a long barrel , is driven by a flange mounted motor placed at the top. the inline grease grease filter is provided along with hose for delivering grease

...more

Motorised Grease Pumps

Lubrite Automatic Single Line Grease Pump consists of Reciprocating Motor Driven Plunger Pump with in built Gear Box. The Pump incorporate a large grease reservoir with a follower plate & tell tale rod. Limit Switch is provided on the top of the reservoir to indicate full and empty level of grease. The pump outlet is connected to Pressure Relief Valve. Bleed Valve is provided on the pump body to bleed air entrapped in the system. Before operating the pump, Bleed Valve is kept open till the continue flow of grease starts from it. The whole system is controlled with Electric Control Panel.

...more

Metering Cartridges

In Single Shot Centralised Lubrication System, amount of oil at each lubrication point is controlled by the element known as Metering Cartridge. For each lubrication point, at least one metering cartridge has to be used. The metering cartridges are Metering Valves where stroke of the Piston determines the amount of oil to be ejected. The Cartridges operate as soon as pressure builds up in lubrication line. When the pump is off and the pressure in the lubrication line drops, Cartridges get recharged for the next cycle. Small time gap(minimum 1 minute) is allowed between the subsequent operations of the Pump for proper recharging of the Metering Cartridges.

...more

Manual Grease Pumps

These are heavy-duty Grease Pumps and are used where the total no. of points are more than 20 or the lubrication lines are lengthy. To avoid the extra load on operator, the handle of the Pump is extra long and is equipped with Lever system. When the handle is pushed, grease is sucked from the reservoir and is ejected under pressure by pulling the handle out. These Pump are wall mounted and should be installed vertically at a place conveniently accessible to the operator. In case of Plant Lubrication with various machines, the distributors or Progressive Blocks are mounted on each machine and the pump is mounted on the trolley to lubricate the plant with the help of Flexible Hose Pipe and Quick Release Coupling.

...more

Manual Dual Line Grease Pump

This is Plungger Type Pump Operated Manually by a lover (handle). The pump housing has inbuilt spool type manual line changer. which directs the grease alternately in the two outlets. The end of each greasing cycle is indicated by rise in pressure through pressure gauge. The Pump is provided with grease reservoir, which has a follower plate and tell tale rod to indicate the level of grease. The pump is also provided with grease filling port, which can be attached to a suitable filling Pump, for charging the Reservoir with fresh grease. The follower plate together with pump filling device eliminates possible formations of air pocktes within the grease.

...more

Lubrication Timer

Electronic timers are used to maintain the Lubrication cycle in automatic single shot Lubrication Units. It is basically ON - OFF timer with following technical specifications.

...more

Leading Rotary Pump

At our semi-automated production line we manufacture Flange Type Rotary pumps, Insert Type Rotary Pumps and Dual Direction (Bi-directional) Rotary Pumps. Smooth, durable and trouble free operation ensures that the lubrication of various application such Head-Stocks, Gear-Boxes and Re-calculating Units remains optimum and un-interrupted. Over four decades of hardcore experience in manufacturing state of the art Lubrication Pumps has helped us develop such 100% reliable and quality products which lasts for many years without any trouble. Just to further our commitment to serve you in the best possible way, we at Lubrite Industries has setup a hotline number to ensure that we render our post sales services on just a call from your side.

...more

Junction Blocks

Lubrication line from Pump is further connected to the side port of the Junction Block and the other side port is meant for joining the next Junction Block in line with 6mm OD tube. Metering Cartridges are directly screwed on top outlets of Junction Blocks. Type of Junction Block is selected depending upon the metering cartridges to be fitted. A junction Block should cater all the lubrication points lying in the same vicinity.

...more

hand operated pumps

Hand Operated Single Shot Pumps are spring returned piston type pumps. The piston is operated by pulling the cam handle. These pumps are suitable for manual centralized lubrication for light duty machines such as Small Power Presses, Die Punching Machines, Grinding Machines, pouch Packing Machines, Pharmaceutical Machines and etc. Normally these pumps are recommended for the machines with lubrication points within 2-20.

...more

Hand Operated Lubricators

Hand Operated Single Shot Pumps are spring returned piston type pumps. The piston is operated by pulling the cam handle. These pumps are suitable for manual centralized lubrication for light duty machines such as Small Power Presses, Die Punching Machines, Grinding Machines, pouch Packing Machines, Pharmaceutical Machines and etc. Normally these pumps are recommended for the machines with lubrication points within 2-20.

...more

Hand Operated Grease Pump

Hand Operated Single Shot Pumps are spring returned piston type pumps. The piston is operated by pulling the cam handle. These pumps are suitable for manual centralized lubrication for light duty machines such as Small Power Presses, Die Punching Machines, Grinding Machines, pouch Packing Machines, Pharmaceutical Machines and etc. Normally these pumps are recommended for the machines with lubrication points within 2-20.

...more

Grease Radial Pump

In LUBRITE Grease Radial Pump the Grease Injectors are working unit. Each pumping unit is independent and is actuated by a cam through a Gear Box. The gear box is driven by a Electric Motor. These pumping units are mounted around the Housing of Radial Pump. The pump. The pump incorporate a large reservoir with follower plate and Tell Tale Rod. The pump may rotate in either direction; Grease is pushed down ward with the Follower Plate and Stirrer Assembly. Limit Switch is provided on the top Reservoir to indicate low level of grease in the Pane Box

...moreBe first to Rate

Rate This