Ultrafiltration Reverse Osmosis Plant

Superfil recently added a new feather in their cap manufacturing the ultra filteration & Reverse Osmosis Equipments. We can manufacture the water treatment plants for any capacity using state-of-the-art technology and components.

...more

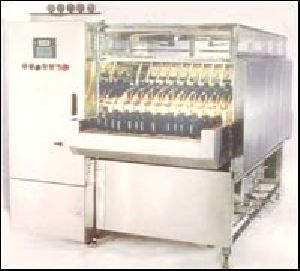

TRIO BLOCK Filler Machine

TRI-O-BLOCK Neck Superstar The term trioblok is used for a combination of rinser, filler & closure equipment. It incorporates rinsing, any type of filling & closing system. Various combination are possible depending upon the type of product, container, closure, & capacity required Neck superstar is an innovative technology of rinsing, filling, capping & bottle handling of international standard. It allows handling without equipment change over, for bottles with different sizes & diameters. Salient Features Unique design for pet handling No change parts reqd. except at outfeed No height adjustments reqd. for different pack sizes No physical contact between bottle & washing nozzles Adjustable vent tube for different fill height Collapsable capping head Adjustable permanent magnet torque head Non lubricating gear train, bushes & capper turret All safeties encorporated in plc

...more

syrup tanks

Semi Automatic Rotary Gravity Filler

Application Widely used for filling Mineral water, Milk, Juice, Liquor, Still Drinks in glass/HDPE/LDPE/PET/PVC bottles/ containers No of Filling Nozzles 6,9,12 Approximate Output Output based on 1Litre Bottle: No of Nozzles: 6 -> Output: 18 No of Nozzles: 9 -> Output: 27 No of Nozzles: 12 -> Output: 36 Power Requirement 1 HP/3 Phase Air Requirement 0.75 cfm at 5 Kg for 6 Nozzles1.25 cfm at 5 Kg for 9 Nozzles1.75 cfm at 5 Kg for 12 Nozzles Construction M.S. duly cladded with S.S 304 contact parts are made out of S.S. 304(S.S. 316 optional)

...more

Semi Automatic Rotary Counter Pressure Filler

Semi Automatic Linear Volumetric Filler

Semi Automatic Linear Vaccum Filler

Semi Automatic Linear Gravity Filler Machine

Semi Automatic Linear Counter Pressure Filler

semi automatic labelling machine

Salient Features: Works without any change of machine parts for round containers from 10 ml to 3 litres Suitable for labeling on Round Shaped Metal, Glass, Plastic, PET and Composite containers Works on cold glue - with minimum gum consumption Compact and portable Model. Suitable for face and wrap around(100% of circumference) labeling. Almost all the parts are made from Stainless Steel , to avoid rusting, when washed with water Cleaning of glue pan and other parts requires no time and skill Conforms to 'GMP' standards Requires minimum power consumption Suitable for labeling on long/short neck bottles e.g. Brute shaped bottles Applications: Pharmaceuticals Chemicals Cosmetics Food & Beverages Distilleries & Breweries

...more

Semi Automatic Jar Washer

Application : Widely used for washing mineral water jars of 20 & 25 ltrs.

Capacity : 5-6 jars per minute

Semi Automatic Jar Scrubber

Application : Widely used for washing & brushing mineral water jars of 20 & 25 ltrs.

Semi Automatic Jar filler and Capping Machine

Semi Automatic Cup Filler Machine

Semi Automatic Bottle Washer Machine

Semi Automatic Bottle Rinsing Machine

Application : Rinsing of PET, HDPE, LDPE, PVC & Glass new bottle / Cups /Containers.

Roller Conveyors

Processing Equipments And Tanks

Gentle & careful processing is the key to success for any product. Superfil offers state of the art solution for processing: Fruit juices Carbonated soft drink Water Still drinks, etc. They include: Ultra Filteration & Reverse Osmosis Syrup room equipments Carbonators CIP System

...more

Pet Bottle Conveyor

Pasteurizer And Homogenizer Machine

Hot fruit beverage is Homogenized & Pasteurized. The Pasteurization is done through Plate/ Tubular/ Spiral Flow/ Scrapped Surface Type Heat Exchangers & Homogenized through high pressure homogenizer. The processed juice can be hot filled in glass bottles or in pet bottles.

...more

Monoblock Machine

The term monoblock is used for a combination of filler & closure equipment. It incorporates any type of filling & closing system. Various combination are possible depending upon the type of product, container, closure, & capacity required.

...more

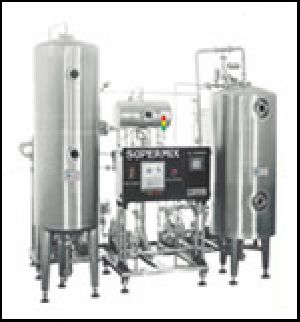

Supermix Machine

Supermix is a proven system for preparing carbonated drink. It works on a principle of brix control & ratio control, which ever mode is selected. Carbonation is done under controlled flow of co2 with respect to the flow of beverage & gas volume required.Operating Procedure Degassing of Product Water Mixing Cooling Carbonation CIP Salient Features Direct Control of Brix rather than Ratio. The Brix is directly controlled using mass flow meter for measurement, for any deviation in the set point & achieved point the syrup flow is controlled to achieve in terms of brix required. Controlled Injection of Co2 in terms of gm/litre. The Co2 is injected in gms/litre. For any change in the flow rate of beverage the amount of CO2 to be injected changes automatically. The change in line pressure of CO2 is compensated automatically, with in the set limit of CO2 pressure. Different CO2 pressure settings Injection pressure of CO2 & buffer tank pressure can be set differently. No manifold & hand valves for different mode of operation. There is no requirement of any change over manifold & hand operated valves for running the machine indifferent modes. ( like CIP, Discharge, Production). Once the mode of operation of machine is selected all the valve change their position as per the mode requirement. Man Machine interface The top of end communication between operator & machine. Complete alarm history. Trends can be created & saved for production. Additonal benefits Replacement hand operated flow control valve with electronic control. Remote operating Interface of the machine. The machine can be operated & controlled in full respect sitting in the office itself. Customized Recipe module with real time trends. Real time trends stored on hard disk for analysis purpose. Shift wise/ day wise MIS reports for quantity produced, Mixer Usage etc. Zero dumping i.e. the perfect drink from first bottle.

...more

Linear Bottle Washers Machine

Juice Pasturiser Machine

Be first to Rate

Rate ThisOpening Hours