Mild Steel Bag Filter

20,000 - 80,000 Per piece

A mild steel bag filter is a type of industrial filter used to remove dust, particles, and other impurities from air or gas streams. The filter consists of a series of cylindrical bags made of woven fabric or felt, which are supported by a frame made of mild steel.

Bag Filter

Get Price Quote

Very Economics design. At High Contamination Level , Pre-Filter is used. Bag filter is very Affordable Pre-Filter & many times it also used as a Final Filter. Advantage of Bag Filters High Solids Collection Capacity Easy In Maiontain, Reduces Manpower Low Cost Operation Contaminant Retained In Bag Is Easy In Disposal High Efficiency & Performance Bag Filter Housing We use polypropylene or polyester for manufacturing Bags. Commonly, woven materials are used to make bags. Fine Filtration non woven media is preferred for use. We also supply heat-sealed hand bags colored with polypropylene color. We use color for holding on the bag in house. The direction of filtration is from in to out. Fluid comes into your bag from the top of housing and this fluid is paased through perforated cylinder from bag. When bag will be full of contamination, it is must to clean that bag by taking out from housing or exchange with newer one. We manufacture Bag Filter Housing with the standard size as 7”x33” and 7” x 14”. we also produce customized Bag Filters as per the pre-requirements of our clients. We can use Multi Bag Filter if there is high flow rate. Our general bags are available in the size of 5 to 100 micron.

Best Deals from Bag Filters

Bag Filter

Get Price Quote

Techno-Filt International is Manufacturer and Supplier of Bag Filter in India. The durable and cost-effective filter vessel is resistant to a comprehensive range of chemicals It allows the user to choose the filter media and supply accurately to fit their specific requirements. Our company is the leading exporter of bag filter housings. Original innovations have been the logic for a vastly varied range of vessels to meet the high demanding as well as standard uses from single to multibag housings, stainless steel to engineered plastic vessels. The advantages of bag filters are – High solids collection capacity. Easy change out saves manpower, Cheapest solution, Contaminant retained in bag is easy for disposal, Minimum loss of processing fluids etc. Bags are made from polypropylene or polyester. Usually woven material is used for making bags. For finer filtration non-woven media is superior. It is accurately stitched at the joints and the top rubber color. Color is used to hold the bag in the housing as shown here in the picture. A dispenser is inserted in to the bag housing to hold the bag and avoid by-pass. The bag is rested on perforated cylinder. The filtration is in to out in bag filter. Fluid enters from the top of the housing in to the bag. Contamination retains on the bag and clear fluid passes from bag through perforated cylinder. Once bag is full of contamination, one wants to clean it by taking it out from the housing or replace it with different one. Regular size of the bags is 7″ x 33″ and 7″ x 14″. However it can be made of any size as per the necessity. In case of high flow rate, multi bag housing can be provided to take care of the flow. Standard bags are accessible from 5 to 100 micron cut-off range.

Bag Filters

1,000 - 30,000 Per Piece

1 Piece (MOQ)

Metflow Engineers is the best bag filter exporter in India. Compact design, Handles large air volumes, Front door facilitates, easy access to bags, Downward flow direct, helps easy separation, More intensive & efficient than any current mechanical or previous Scavenging systems. Function & Operating Principles The Filter elements are cleaned at Automatically controlled regular intervals via individual solenoid valves. This is achieved during operation using a blast of compressed air Lasting a fraction of a second. This reverses the flow direction briefly in the Particular element. The injection effect of the blast nozzle entrains Secondary air from the clean air space. This greatly increases the cleaning Efficiency. Contact us and order our bag filters today.

High Flow Multi Cartridge

Get Price Quote

We have gained expertise in offering a supreme quality SS Bag Filter Housing to the esteemed customers. These housings are manufactured using high-grade raw material procured from some of the reliable vendors of the industry, with the help of our procuring agents. Our range is offered to the clients at industry leading prices.

reverse pulse jet bag filter

Get Price Quote

Everybody wants to have clean and pollution free air around, and since industries are more responsible for Air pollution. We combat this section. There are several varieties of Bag Filter A Dust Collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector system consists of a blower, dust filter, a filter-cleaning system, and a dust receptacle or dust removal system. It is distinguished from air cleaners which use disposable filters to remove dust. In reverse-pulse-jet Bag Houses, individual bags are supported by a metal cage (filter cage), which is fastened onto a cell plate at the top of the Bag Houses. Dirty gas enters from the bottom of the Bag Houses and flows from outside to inside the bags. The metal cage prevents collapse of the bag. Bags are cleaned by a short burst of compressed air injected through a common manifold over a row of bags. The compressed air is accelerated by a venturi nozzle mounted at the Reverse-Jet Bag Houses top of the bag. Since the duration of the compressed-air burst is short (0.1s), it acts as a rapidly moving air bubble, traveling through the entire length of the bag and causing the bag surfaces to flex. This flexing of the bags breaks the dust cake, and the dislodged dust falls into a storage hopper below. Reverse-pulse-jet Dust Collectors can be operated continuously and cleaned without interruption of flow because the burst of compressed air is very small compared with the total volume of dusty air through the collector. Because of this continuous-cleaning feature, reverse-jet dust collectors are usually not compartmentalized. The short cleaning cycle of reverse-jet collectors reduces recirculation and redeposit of dust. These collectors provide more complete cleaning and reconditioning of bags than shaker or reverse-air cleaning methods. Also, the continuous-cleaning feature allows them to operate at higher air-to-cloth ratios, so the space requirements are lower. This cleaning system works with the help of digital sequential timer attached to the fabric filter. This timer indicates the solenoid valve to inject the air to the blow pipe.

bag conversion system

1,200,000 Per Piece

Bag Filter

Get Price Quote

Everybody wants to have clean and pollution free air around, and since industries are more responsible for Air pollution. We combat this section. There are several varieties of Bag Filter A Dust Collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector systemconsists of a blower, dust filter, a filter-cleaning system, and a dust receptacle or dust removal system. It is distinguished from air cleaners which use disposable filters to remove dust. In reverse-pulse-jet Bag Houses, individual bags are supported by a metal cage (filter cage), which is fastened onto a cell plate at the top of the Bag Houses. Dirty gas enters from the bottom of the Bag Houses and flows from outside to inside the bags. The metal cage prevents collapse of the bag. Bags are cleaned by a short burst of compressed air injected through a common manifold over a row of bags. The compressed air is accelerated by a venturi nozzle mounted at the Reverse-Jet Bag Houses top of the bag. Since the duration of the compressed-air burst is short (0.1s), it acts as a rapidly moving air bubble, traveling through the entire length of the bag and causing the bag surfaces to flex. This flexing of the bags breaks the dust cake, and the dislodged dust falls into a storage hopper below. Reverse-pulse-jet Dust Collectors can be operated continuously and cleaned without interruption of flow because the burst of compressed air is very small compared with the total volume of dusty air through the collector. Because of this continuous-cleaning feature, reverse-jet dust collectors are usually not compartmentalized. The short cleaning cycle of reverse-jet collectors reduces recirculation and redeposit of dust. These collectors provide more complete cleaning and reconditioning of bags than shaker or reverse-air cleaning methods. Also, the continuous-cleaning feature allows them to operate at higher air-to-cloth ratios, so the space requirements are lower. This cleaning system works with the help of digital sequential timer attached to the fabric filter. This timer indicates the solenoid valve to inject the air to the blow pipe.

Pulse Jet Bag Filter

2,200 - 3,500 Per Bag

Air Filter Bags, air pleated bags, Air Pollution Control Equipment

Bag Filter

Get Price Quote

Stainless Steel Filters, liquid filter, Polypropylene Cartridge

cartridge bag filter

Get Price Quote

cartridge bag filter, Stainless Steel Filter Housings, Bag Filter Assembly

Bag Filters

Get Price Quote

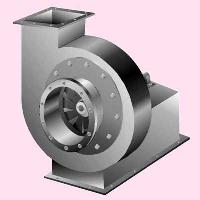

Centrifugal Fans, Air Washers, rotary air filters, Disc Filters

Bag Filter

Get Price Quote

Kettle, Agitators, Vessel, REACTOR

Bag Filter

Get Price Quote

Candle Filter, frame type filter

Bag Filter

Get Price Quote

air pollution control equipments, dust extraction