Ribbon Blander

Get Price Quote

Where a fine blending or mixing of material, with uniform output is required Ribbon Blenders are the best. The equipment is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 10000 litre. The design of the equipment also makes suitable to dry stage reaction for the application such as starch, gum and cellulose derivatives. These blenders are also available with all contact parts of Stainless Steel. Construction : M.S. / M.S. - S.S Coating / S.S / Jacket Ribbon Blender Models Available : MS Blender MS. SS Coating Blender Jacket Blender Till Till Blender Ideal For: Mineral & Others Chemical Technical Products Dyestuffs Pigments Colours Fertilisers Metal Separation Insecticides / Pesticides

Ribbon Blender

Get Price Quote

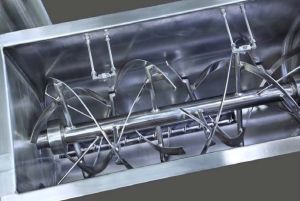

Based in Ahmadabad, Gujarat, we are known as one of the important manufacturers and suppliers of Ribbon Blender which are used for a homogenous mixture of powders and dry granules. Almost two third of the container should be filled with materials for proper mixture. Because of its unique shape and design, this product helps in perfect blending granules and dry powder and is used in various industries like pharmaceutical, cosmetic, food and chemical. The blender has a U shaft along with two spiral ribbons; one positioned within the other, so that material reaches every corner of the trough and has a perfect blend of linear and radial motion for fine powder. The agitator construction helps in triple mixing and efficient blending. Based on a SS/MS structure, this product has a double ribbon configuration which helps to discharge the material through a central bottom outlet. A valve, designed in the centre helps in the discharge procedure. The machine can also be fitted with a spray nozzle with pressure spraying system for spraying additives.

Best Deals from Blender

Mild Steel Conical Ribbon Blender

100,000 Per piece

1 piece (MOQ)

Ribbon Blender

150,000 - 380,000 Per piece

1 piece (MOQ)

The RIBBON BLENDER is ribbon mixer machine widely used for the manufacture of dry powder, talcum powder, granules, spice and low-viscosity paste and liquid in chemicals, pharmaceuticals, food and cosmetics industries. It’s especially suitable for mixing solids with solids and solids with liquids, Approximate two third of the volume of the container of Ribbon Blender/mixer is filled to ensure proper mixing. Ribbon Blender mixer is Suitable for Pharmaceutical Materials, Crystalline, Insecticides, Pesticides, and Food industry and heat sensitive, Chemical and Cosmetic products handling large Dry and wet powder volume. It consists of a horizontal “U” Vessel with horizontally installed shaft. Hexacon Enterprises make Horizontal Ribbon Blenders is an high efficient and versatile blending machines for mixing of dry powder, granule and viscous paste homogeneously. Ribbon blender mixer to given perfect r mixing due to the innovative designs of spiral agitators inside of its U-shape Cone chamber. Ribbon blender with Screw conveyor , ribbon blender with bin , ribbon blender with sifter , ribbon blender with product transfer input and output , liquid spray systems, working plat form with variable speed drive or PLC base operation we offer as per customer product and process , Horizontal ribbon mixers range from 50-25000L or more capacity as per requested by customer . Ribbon blender and mixer with stainless steel construction or Mild steel construction main body with stainless steel U shape mixer with bottom product discharge manual and auto valve , control panel , product bin etc we offering as per customer demand for wide industreis Food, Cosmetic, Waterproof Porcelain Glazed Polished Vitrified Tile Strong Adhesive, Floor Adhesive /Ceramic, Chemical, Plastic , Dry Powder, Putty, Modified Corn Starch, Real Stone Paint, Animal feed, Pharmaceutical, Fertilizer, Plastic, Battery etc…… We offer Quality with best mixer machines, mixing machine, blender, powder mixer manufacturers and suppliers by Shree Bhagwati Group of companies. RIBBON Mixers has been developed with advanced technology to achieve high blending capabilities and is among the most efficient machines in the market. The ribbon mixing equipment can be used in either the batch or continuous flow form to achieve an even and homogeneous blend in a wide range of products. The blending technology is widely used in industries such as pharmaceutical industries, food processing, animal feed processing, chemical, fertilizers, cosmetics, pigments, and also insecticides manufacturing. The vertical blender mixer is also important in the process of distribution of liquids and pasty products in micro dosages on to carriers. Capacity FROM 50 LITERS TO 15000 LITERS The ribbon blender machine comprises of a horizontal U shaped trough and a specially developed a double helical, fabricated ribbon agitator that rotates within the trough. The machine design is based on a proven agitator technology that efficiently achieves triple mixing action and ensures fast and efficient blending. The equipment dimensions and design of the operating parts are well balanced to provide balanced material movement within the container and avoids dead spots while rapidly discharging the product. The ribbon mixer machine is made with user friendly features such as wear resistance, corrosion resistant, vacuum filling and discharge arrangements, special shaft seals, heating and cooling jackets and in a variety of sizes and models for specialized applications. The operating capacity of the ribbon blender mixer ranges from 100 liters up to 8000 liters capacity, and it is constructed with stainless steel for maximum durability.

Ribbon Blender

25,000 - 500,000 Per piece

1 Piece (MOQ)

600 KG Double Cone Blender

200,000 Per Piece

1 Piece (MOQ)

Reaction Blender

Get Price Quote

We offer reaction blender. The entire unit is fabricated with engineering precision. Along with the double ribbons that provide to & fro, up & down movement to the powder. Two of chopper blades moving at cutting speed are provided at diagonally opposite sides to break lumps of the mixture. It accurately and rapidly blends small proportions into large stocks. Ribbon blender is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 15000 liter.

Reaction Blender

Get Price Quote

The entire unit is fabricated with engineering precision. Along with the double ribbons that provide to & fro, up & down movement to the powder. Two of chopper blades moving at cutting speed are provided at diagonally opposite sides to break lumps of the mixture. It accurately and rapidly blends small proportions into large stocks. Ribbon blender is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 15000 liter.

Container Tumbler Blender

Get Price Quote

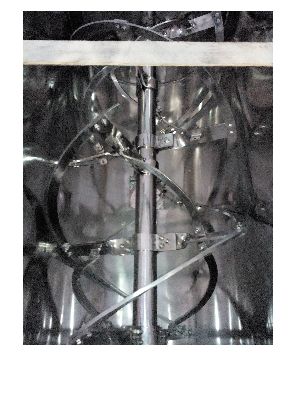

Dust free effective process technik of uniform mixing, lubricating & blending of dry powder & granules Application & Process : Tumbler blenders or IBC Container tumblers are used mainly for blending of dry powders for tablet production and capsule, which facilitates better flow for tablets and capsules. This is a closed contained, totally dust free single step transfer system. It can handle more than one size of IBC container tumblers. In granulation room the dry granules enter to the IBC container for blending through a dust free connection and the same IBC container is loaded over to the blender for blending. The IBC bin locked in the resting frame in 15° then lifted by hydraulic system to up ward for moving height after that the IBC bin rotates for blending. This same IBC container after blending raised over the tablet press for unloading in to the tablet press hoppers. Salient Features : Design is cGMP - Current Good Manufacturing Practices compliance All Product contact parts AISI 316/ 316L & non contact parts AISI 304. IBC Bin Tumbler Blender for Ideal dry mixer for lubrication of granules and homogenization mixing and conveying of the material to further process. Interchangeable different capacity IBC Bin can be used on same machine use for mixing. This is a closed and contained system where by a single step transfer material from Container of the Conta blender is transferred to the tablet press hopper. In granulation room the dry granules enter to the container for blending through a dust free connection and the same container is loaded over to the blender for blending Totally dust free. Also another advantage is adaptability of this system to handle more than one size of bunkers or containers so processing of different sizes of production batches in single equipment. Enclosed rigid drive with reduction gear box and motor in the machine pillar structure. Hydraulic power pack system for lifting of product bin for mixing. A suitable reeling around the cage with one entry point for the bin on detachable trolley The charging hole with cover is provided on top with quick opening and closing arrangement with dust proof joints for particle free transfer. IBC Bin having discharge with butterfly valve and trolley for easy mobility. Electric controls panel with cycle time Optional Features : Interchange able product container. AC Frequency variable drive for product container. PLC Controls with HMI touch screen, Flame proof motor and Push Button station. Safety Features : Limit switch. Overload relay protection & Emergency stop button..

Octagonal Blender

Get Price Quote

Operation: The Octagonal Blender Is An Efficient And Versatile Blending Machine For Mixing And Lubrication Process Of Dry Granules Homogeneously. Two Third Of The Volume Of The Cone Blender Is Filled To Ensure Proper Mixing. The Octagonal Blender Gives Best Result For Granules Due To Very Slow Speed And Octagon Shape Of Container. It Can Be Used For Pharmaceutical, Food, Chemical And Cosmetic Products Etc. In Octagonal Blender The Granules Comes From All Sides Due To The Octagonal Shape Of The Product Container, Hence Requirement Of RPM Is Less. Suitable Mainly For Crystalline & Granular Type Material. This Type Of Material Gets Sufficient Continuous Movement Due To Their Shape If Container Have Only Slow Movement And Will Results In Good Quality Of Blending / Lubrication Of Granules. Special Features: Octagonal Blender Contains Following Main Features uitable For Dry Mixing Of Products In Granule Form. Easy For Loading And Unloading Of Material. Easy For Cleaning. All Contact Parts Are Made Out Of SS 304 / SS 316 Or SS 316 L Quality Material, As Per Customer Requirement. The Octagonal Shape & Slow Speed Of Rotating Gives Sufficient Continuous Movement To The Granules Result In Good Quality. Simple Design Requires Minimum Maintenance. General Structure & Safety Guards Made Out Of Mild Steel & Colored In Standard Model And Made Out Of SS 304 & Polished To The Matt Finish In GMP Model. Maximum Care Has Been Taken To Ensure Safe Operation Of The Unit. Bigger Size Batch At Low Power Consumption. Other Options Available: We Offer Following Other Option For Octagonal Blender Buyers Contact Parts Made Out Of SS316 Instead Of SS304. Flame Proof Drive Motor Along With Flame Proof Starter. Vacuum Loading Facility For Material Charging. Cylindrical Container With Cone For Material Charging. Contact Parts Are Made Out Of SS316 / SS304 Material. Inside & Outside Surfaces Of Contact Parts Will Be Polished To The Mirror Finish. Gear Box: - Standard Make Starter: - D.O.L.

Double Cone Blender

Get Price Quote

We offer highly efficient Double Cone Blender in the international market. The Industrial Double Cone Blender manufactured by us is used for blending with whirling blades for chopping, mixing, or liquefying materials. The output capacity of our blenders depends on the materials to be used. Besides, we are one of the prime Double Cone Blender Machine Manufacturers in India.

Ribbon Blender

380,000 Per Piece

1 Piece(s) (MOQ)

The Mahavir ribbon blender are based on a proven agitator construction that provides a triple mixing action thus ensuring fast efficient blending. The dimensions and configuration of the ribbons in ribbon blender are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge. The design of the Mahavir ribbon blender can in corporate features required for a customer's product or process such as: wear resistance, corrosive resistance, vacuum filling and discharge arrangements, special shaft seals, heating/cooling jackets. Ribbon blender is available in sizes 100-8000 litters in Stainless Steel 304, Stainless Steel 316 and Mild Steel Construction.

Ribbon Blender

Get Price Quote

Model : 0.5 HP 100 HP 25 litter to 25,000 litter Capacity Direct Gear Drive , Counter Gear for load reduction Constraction : MS - MS / SS Coating – SS Material – Jeketared With and Without Counter Gear Ideal For : Pigment Colors - Minerals & Ores - Chemicals Technical Products Dyestuffs - Fertilizer - Insecticides - Pesticides Extra Material Handling Screw for loading & Unloading. HP required 2 HP 1440 Electric Motor 2 Nos. Capacity input and out material 75 kg per one minutes

Ribbon Blender

560,000 Per Piece

Ribbon Blender

Get Price Quote

The RIBBON BLENDER is an efficient and versatile blending machine for mixing of dry granules & powders homogeneously. Approximate two third of the volume of the container of Ribbon Blender is filled to ensure proper mixing. The Ribbon Blender gives best result for mixing of dry powder & granules due to the design and shape of the mixing ribbon and product container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. Material should be charge from the top side. There are port/ports should be provided on the top cover to charge the material as well as for air vent. One discharge valve provided at the bottom side at center of the container. The discharge height could be adjust as per the requirement, so that material gets discharge in the other container directly, so that material handling time for discharge is nil and the operation is dust free In Ribbon Blender the powder moves from center to the end of container and end of container to the center of container. Hence requirement of total mixing time is very less and the RPM required are also very less. The dry material gets sufficient continuous movement due to the shape & movement of ribbon & shape of the container. Which moves material for good quality of blending? The unit is consist of one electrical motor, one worm reduction gear, belt drive between motor and gear, couple drive between gear to ( ribbon ) mixing stirrer. Container having four nos. of legs with discharge valve & top cover. Both end of mixing shaft is sealed with bush & PTFE gland housing & safety guards are provided on all moving parts.

Industrial Blender

150,000 - 7,500,000 Per Piece

1 Piece (MOQ)

V Blender

Get Price Quote

All type of Blenders are available for Mixing i.e. Octagonal Shape, V Shape, Double Cone, Cage, Cone & Ribbon Blender in the MOC of Contact Parts S.S.316.

Juicer Mixer Blender

9,000 Per

1 Piece (MOQ)

Octagonal Blender

200,000 - 650,000 Per Piece

1 Piece(s) (MOQ)

octagonal blender is designed to process larger volume of material. it occupies less space compared to other similar blenders like v and double cone. power consumption is also less. the blending takes place at low speed during operation. it is well balanced even in higher capacities. it is very useful for pharmaceutical industries where in gentle of dry granules of powder are to be done. it is a slow sped blender and has removable type baffles mounted on a rectangular shell. the important feature of machine is easy to wash in place. octagonal blender is supplied with a bin charging system or can be designed for vacuum charging. dust free charging system is also incorporated, which is a completely closed system for charging and discharging of powders and granules. the power consumption is comparatively lower than other similar types of blenders. the machine basically consists of shell welded with conical octagonal shape ends and supported with sturdy supporters on the both sides. the right-hand side shaft is connected to a standard gearbox by means of chain and sprockets, which in turn coupled to an electric motor. the whole drive assembly is coupled with ss side panel. the inside panel portion of octa body is mirror polished and the outside surface of the octa body, frame & guards are matt polished. the material is to be mixed is charged in the machine either manually from top or bin discharging system or vacuum charging system and then the port is locked positively. then blender is started to pre-set blending time. at the end of process, machine is stopped and the product is transferred to process containers by opening the butterfly valve special feature: material handling in octa blender is through bin charging or vacuum charging system bin charging system ensures dust free closed system for charging and discharging of product slow speed blender with gentle blending of dry granule optional in-built vacuum design. no external pts required the baffles are eliminated with blending profile analysis available. pneumatically actuated valves for dust free transfers bins with level sensory for automatic cut off mechanical seals on shafts for pneumatic connections cgmp design for ease of cleaning

Gravimetric Blender

200,000 - 700,000 Per NOS

1 Nos (MOQ)

Octagon Blender

Get Price Quote

In keeping with our theme of client satisfaction, we are offering Octagonal Blender. Octagonal Blender is considered to be high effective blending machine. It could efficiently mix dry granules and apply lubrication process with ease. This Octagonal Blender is proven for its reliable performance. Owing to its octagonal shape, it could easily process large volume of material in comparison to V and double coned blenders.

Ribbon Blender

Get Price Quote

We are offering ribbon blender we have a state-of-the-art manufacturing facility, which helps us providing our clients with ribbon blenders. Ribbon blenders available size from 200 mm diameter to 2500 mm diameter in mild steel & stainless steel.

Double Cone Blender

Get Price Quote

The double cone blender is used to produce homogeneous solid-solid mixture. Mixing is a common process step in the manufacture of products for industries such as healthcare, food, chemical, cosmetics, detergents, fertilizers and plastics. Product Description Ideal for Mixing of powder and homogeneous lubrication of granules. Double cone blender is provide safety guard with limit switch interlocked to motor For higher capacity model. Available capacity 5 kg. to 1000 kgs. Automatic loading & unloading facilities provided. All parts made it S.S material is used for ss304 / 316 / 316L. It can be used to pharmaceutical,food,chemical and cosmetic product

Ribbon Blender

Get Price Quote

Ribbon blender is used for uniform, homogeneous and quick mixing of powders and semi-wet materials of different densities by specially designed helical ribbon agitator. It can be used for Pharmaceutical, Food, Chemical, Dyestuffs & Pigment etc. For Pharmaceutical Industries, Ribbon Blender is called as Mass Mixture. Uni-Mech manufactures Continuous type and Batch type Ribbon Blenders. Uni-Mech also designs Ribbon Blenders for Chemical Reactions with Heating & Cooling applications. Ribbon Blender Design Range : Capacity range: 5 liters to 15000 liters Material of Construction: Various grades of Stainless Steel, Mild Steel, Hastelloy (cGMP model is also available). Special Features : Homogeneous Mixing Dust Free Operation Easy Handling & Operations Top Charging & Bottom Discharge through Butterfly Valve / Sliding Gate

Ribbon Blender

Get Price Quote

Raj Ribbon Blenders are available from Lab model to Heavy duty model. Ribbon Blender is a light duty blender, useful for easy mixing powder components it is a LOW SHEAR Mixer, most commonly used for SOLIDSOLID, SOLIDLIQUID Mixing and when high shearing force is not required. Its counter flow helicoid flight mounted on shaft ensuring gentle mixing.

Ribbon Blender

500,000 Per Piece

1 Piece (MOQ)

Plough Blender

Get Price Quote

We manufacture superior quality plough mixer that are used for different blending, mixing and drying processes. The machines provide perfect homogeneous blends for dry, fine as well as coarse powders, grains and pastes.These mixers find application in industries like pharmaceuticals, brake lining, cement, chemicals, cosmetics, dyes, fertilizers, foodstuffs, paints etc. Our range of plough mixers can be availed with optional jacket for cooling and heating applications.

U-Mixer Cum Ribbon Blender

Get Price Quote

Very widely preferred machine for mixing and blending solid-to-solid different powders or to blend a small quantity of liquid with huge quantity of powder. Most economical way of mixing the powder if the moisture contain is not high. Available in different construction like SS 304, SS 316 etc. If require, heating or cooling jacket may be provided.

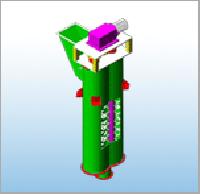

Vertical Continuous Blender

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufucturing of Vertical Continuous Blender to Mixing the Material.This continuous mixer is use for solid-solid and solid-liquid mixing for medium to large production on continuous basis. This mixer have double shaft with adjustable mixing paddles. In vertical mixer the mixing purpose can be solved under gravity force with interned impact. The output production range of this mixer is 100 Kgs. to 50000 Kgs.

Reaction Blender

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufacturing of Reaction Blender for mixing machinery.The entire unit is fabricated with engineering precision. Along with the double ribbons that provide to & fro, up & down movement to the powder. Two of chopper blades moving at cutting speed are provided at diagonally opposite sides to break lumps of the mixture. It accurately and rapidly blends small proportions into large stocks. Ribbon blender is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 15000 liter.